Automatic wedge bonding method on micro bonding pad in overlaying or side-by-side manner

An automatic, wedge welding technology, applied in the field of microelectronics, can solve problems such as breakage, lead wire contact deformation, etc., to achieve the effect of reducing size, reducing quantity and improving coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] In this example 1, the improved wedge knife is used to perform overlapping wedge bonding on the micro-pad, so as to realize superposition bonding of 2 leads on the micro-pad by using an automatic wedge bonder.

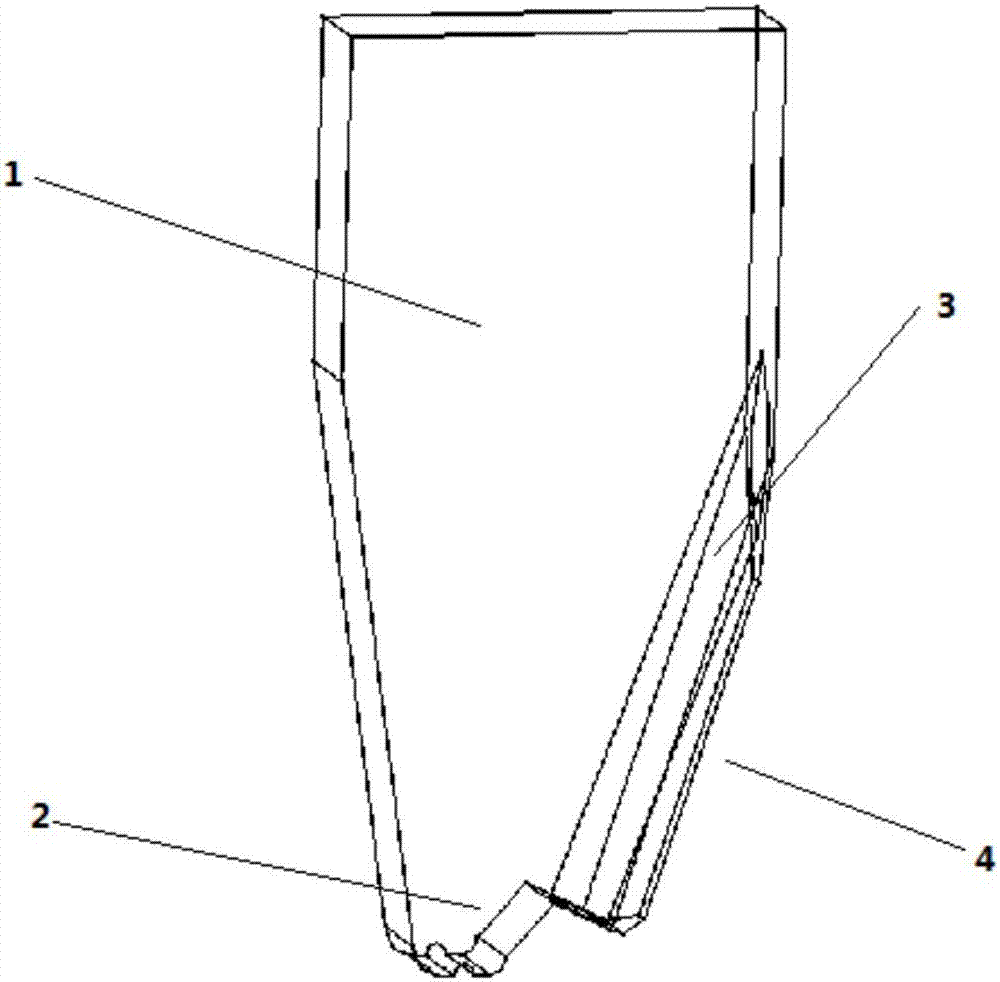

[0052] The structural schematic diagram of the improved automatic wedge-bonded hacking knife in Example 1 is as follows: figure 1 shown. It includes a rivet main body 1, a rivet end 2 and a thread hole 3, the rivet end 2 is located at the end of the rivier main body 1, the thread hole 3 runs through the rivier main body 1 and forms an angle with the side of the main body, A notch 4 is formed on the side of the riving knife end 2 .

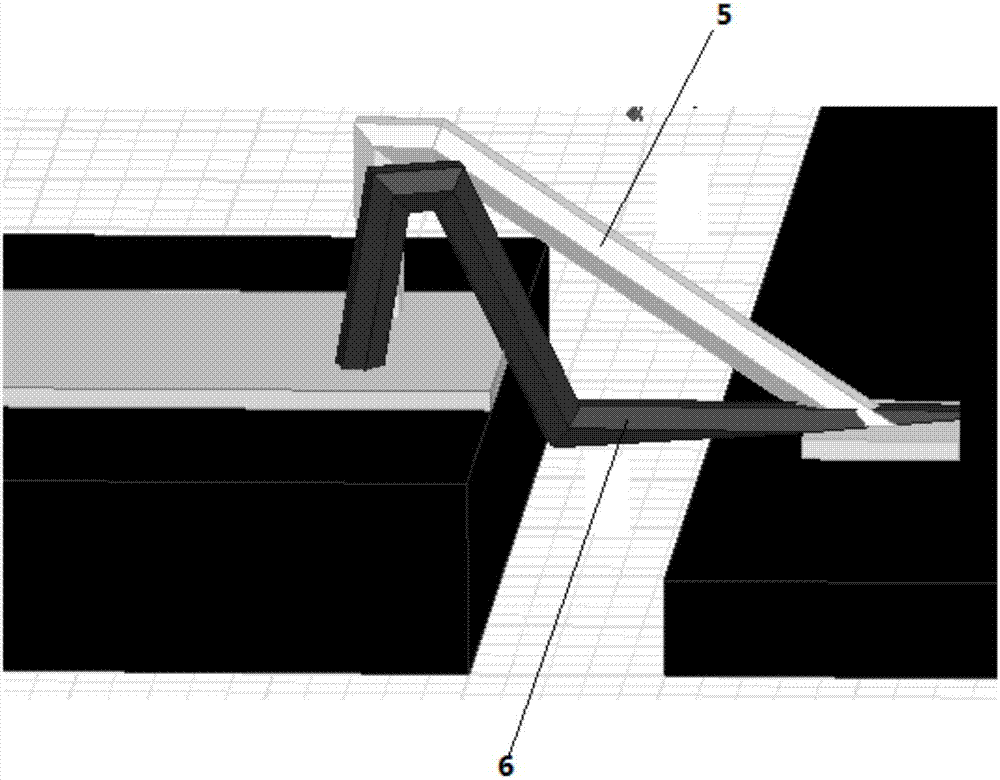

[0053] In this example 1, the improved automatic wedge-bonded rivet is used, and a notch 4 is formed on the side of the end 2 of the rivet, which can effectively prevent the end 2 of the rivet from deforming or even breaking the bonded leads. The schematic diagram of the interference of two wires superimposed and bonded by using an...

example 2

[0059] In this example 2, an improved rivet is used to perform side-by-side wedge bonding on the micro-pad, so that two wires can be bonded side by side on the micro-pad by using an automatic wedge bonder.

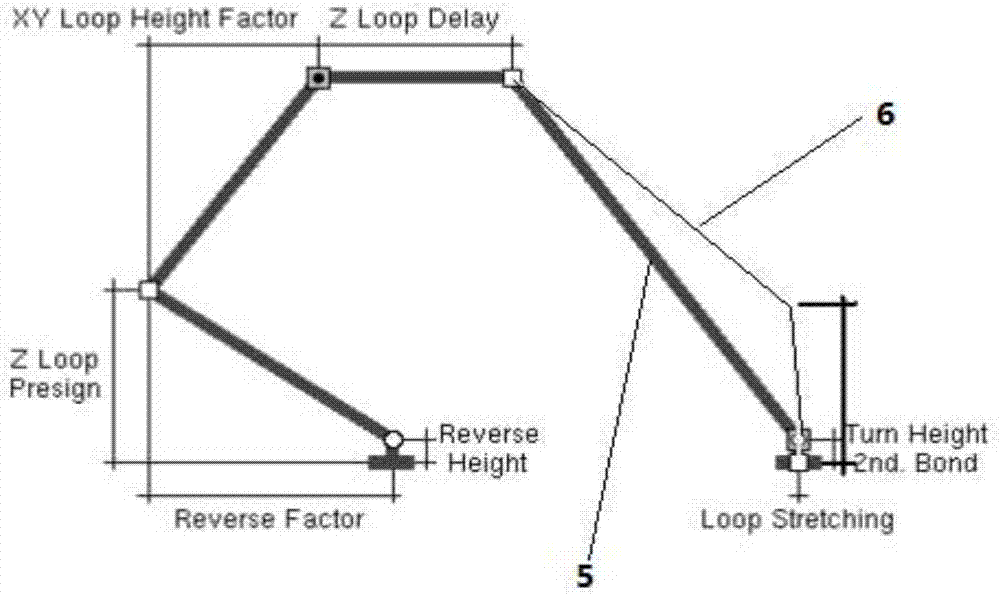

[0060] Figure 5 The top view of the side-by-side bonding structure of the micro-pads with two leads that are obtained by side-by-side bonding on the semiconductor chip 8 micro-pads by adopting the improved chopper for example 2; Figure 5 As shown, in this example 2, the specific process of bonding two wires side by side on the 8 micro-pads of the semiconductor chip is as follows:

[0061] Adopting the improved automatic wedge-bonding hacker, on the pad of the substrate circuit sheet 7, adopting common bonding mode, bonding the first bonding point of the first lead 5 to the micro-pad 9 of the substrate circuit sheet 7, That is to realize the bonding of the first lead 5 on the substrate circuit sheet 7 and the semiconductor chip 8 respectively;

[0062] Using the improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com