Sealing structure

A sealing structure and structure technology, which is applied in the field of sealing structures, can solve the problems such as the joint between the flexible wiring substrate 1 and the sealing part 3 is not smooth, and achieve the effects of reliable sealing, improved waterproof performance, and reduced gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

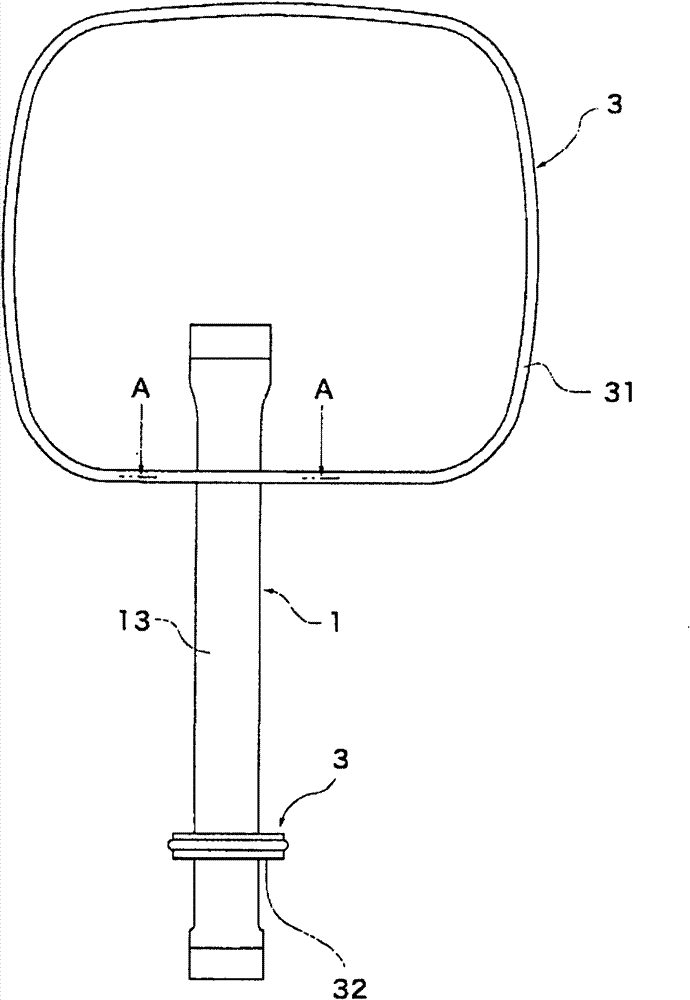

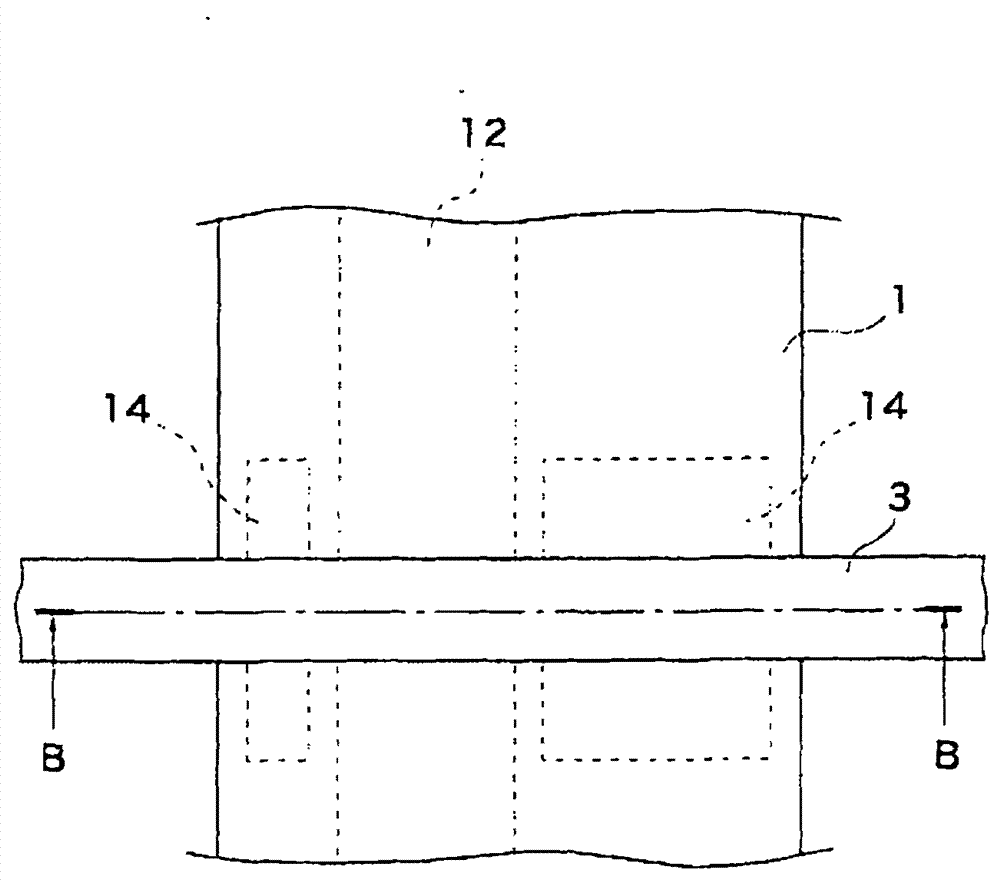

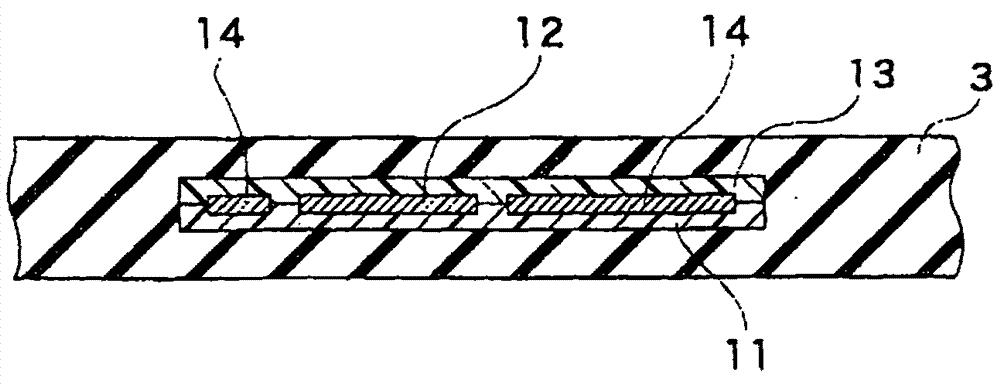

[0062] Below, based on Figure 1 to Figure 5 ,as well as Figure 10 , a preferred embodiment for carrying out the present invention will be described.

[0063] figure 1 is a diagram showing an example of a sealing structure to which the present invention is applied, figure 2 is the first embodiment of the present invention, image 3 shown with the existing example of Figure 6 same place, yes figure 2 The B-B section diagram.

[0064] exist figure 1 Among them, at both ends of the flexible wiring board 1, sealing members 3, 3 having different shapes are integrally formed.

[0065]The upper sealing member 3 in the figure forms a casing-shaped sealing member 31 that simultaneously seals the gap between the housings and the gap with the flexible wiring board 1, and the lower sealing member 3 in the figure forms a seal between the insertion hole provided in the housing and the flexible wiring board. A sleeve-shaped seal 32 for the gap of the wire substrate 1 .

[0066...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com