Battery body

A battery and battery pack technology, applied in the direction of batteries, secondary batteries, battery pack parts, etc., can solve the problems of inability to form resin injection parts, less rise of PTC components, and inability to properly cut off power supply, etc., to achieve easy packaging Overlay, the effect of preventing the rise of the resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

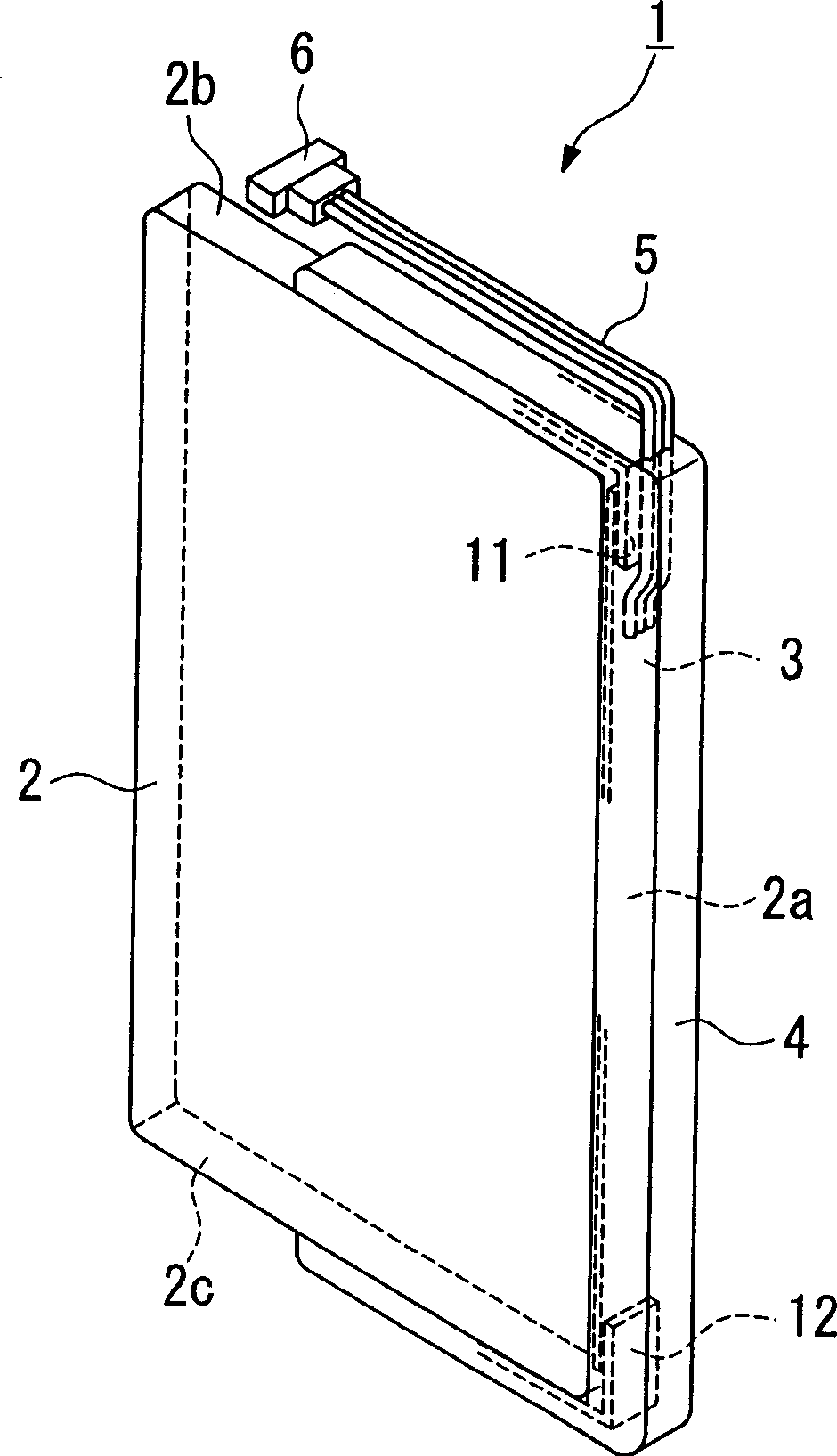

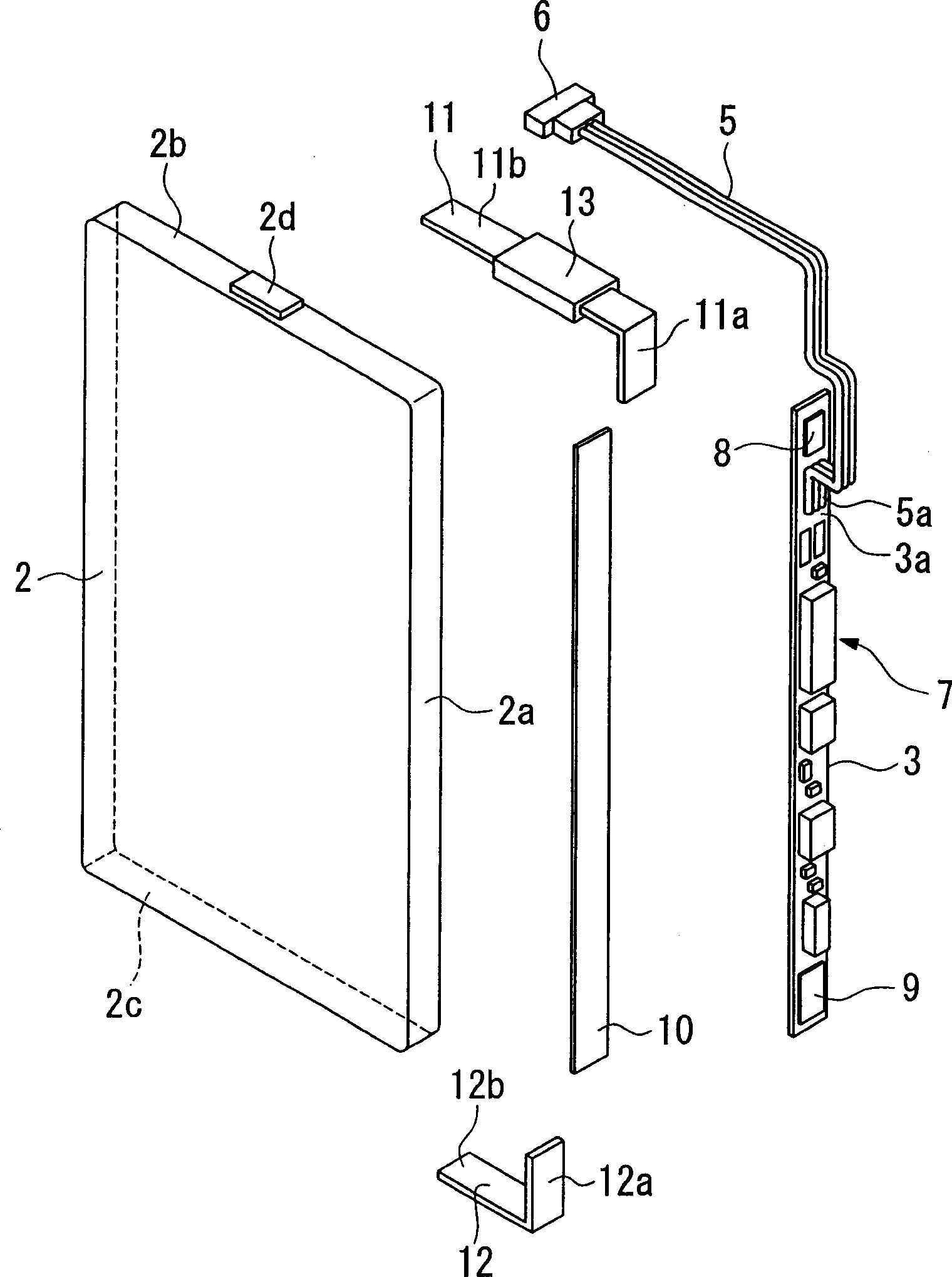

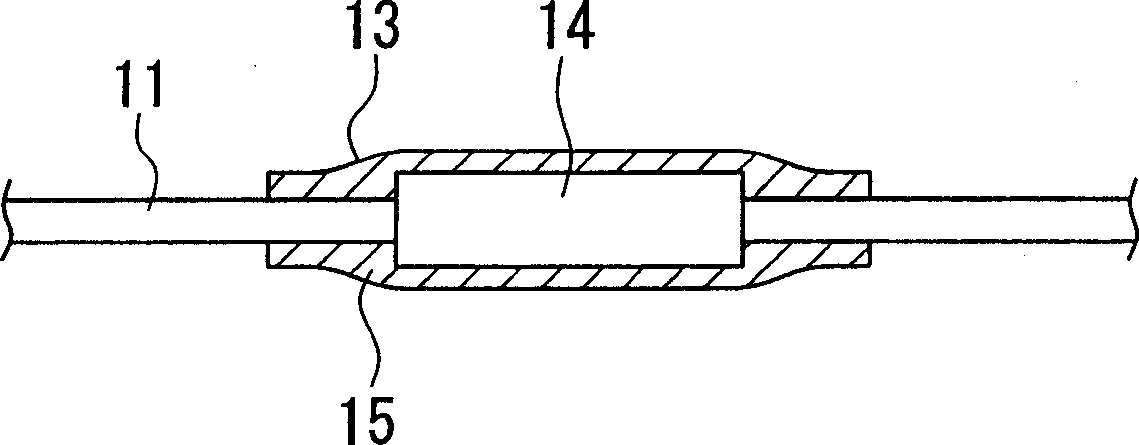

[0033] Figure 1 to Figure 5 An example of the present invention is shown. Such as figure 1 As shown, the storage battery body 1 of the present embodiment is a storage battery body used in a portable electronic device such as a mobile phone, and has a storage battery pack 2 in the shape of a rectangular plate, and a side surface 2a disposed along the storage battery pack 2 The circuit board 3, and the resin injection molding part 4 that wraps the circuit board 3 and is fixed on the side surfaces 2a, 2b, 2c of the battery pack 2, and the cable 5 drawn out from the resin injection molding part 4 and is arranged on the front end of the cable 5 , and form a connecting terminal 6 electrically connected to the electronic instrument.

[0034] On the side 2b of the battery pack 2, such as figure 2 As shown, the protruding negative terminal 2d is arranged in the center, and the other surfaces are positive terminals. In addition, the protruding negative terminal 2d is electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com