Method for determining the cut quality of a laser cutting process using a simulation program

A laser cutting, laser cutting machine technology, applied in laser welding equipment, design optimization/simulation, manufacturing tools, etc., can solve problems such as unknown physical reasons and inability to achieve 10μ radiator cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

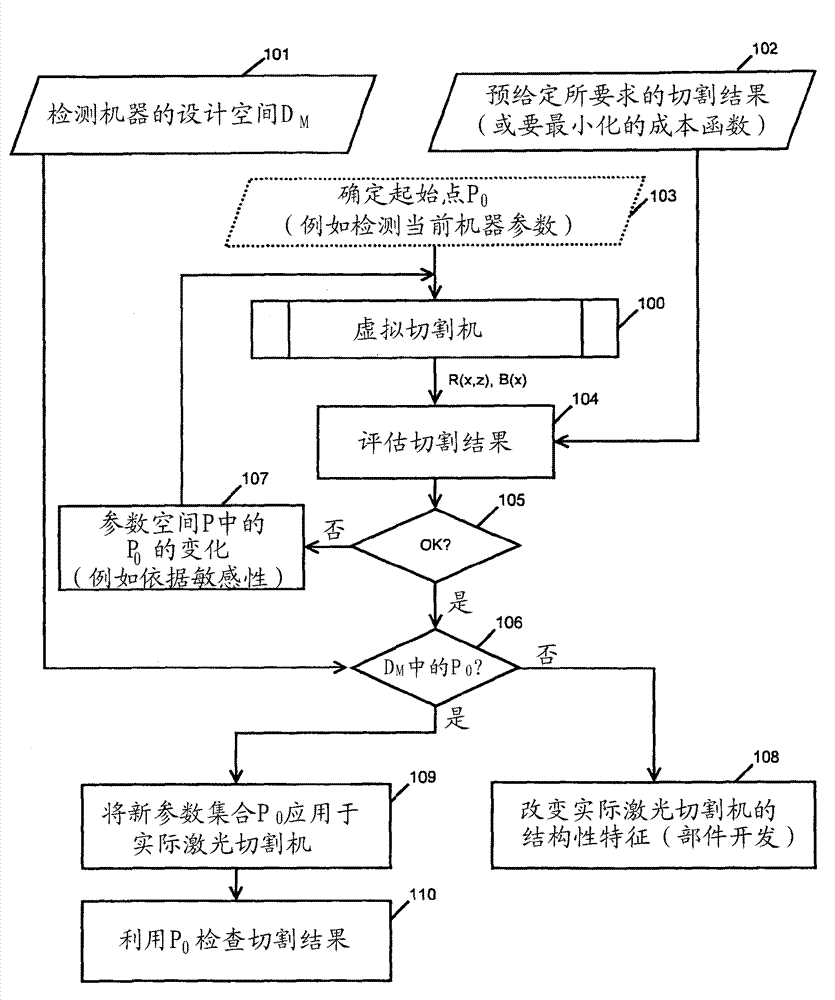

[0132] The method according to the invention (as shown in this figure) uses a virtual cutter, which is identified with the reference numeral 100 . To carry out the method, on the one hand examine (erfassen) the design space D M (step 101), and on the other hand input the required cutting result (step 102). A cost function to be minimized may also be determined in step 102 .

[0133] In order to start the virtual cutting machine 100, a starting point P is determined in step 103 0 , for example, is determined by detecting the machine parameters of the current actual cutting machine. Value P 0 The set of is selected from the parameter space P, as it was further defined before.

[0134] The simulation program is initiated by generating a virtual cut using a virtual cutting machine, which may be based on actual values. The simulation program outputs a cutting result containing the spatial distribution R(x,z) of the ridge amplitude on the cutting surface and the spatial distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com