Curable resin composition, dry membrane and printed circuit board using same

A technology of curable resin and composition, applied in printed circuit parts, secondary processing of printed circuit, photosensitive materials for opto-mechanical equipment, etc. problems, achieving the effects of low flame retardancy, low warpage, low environmental burden, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

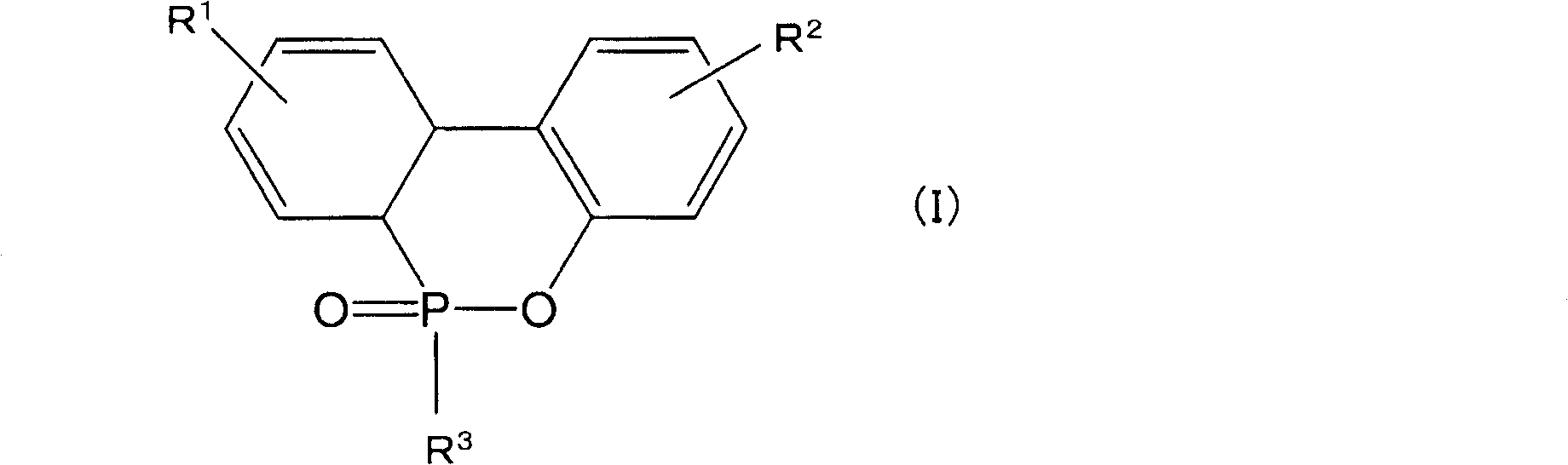

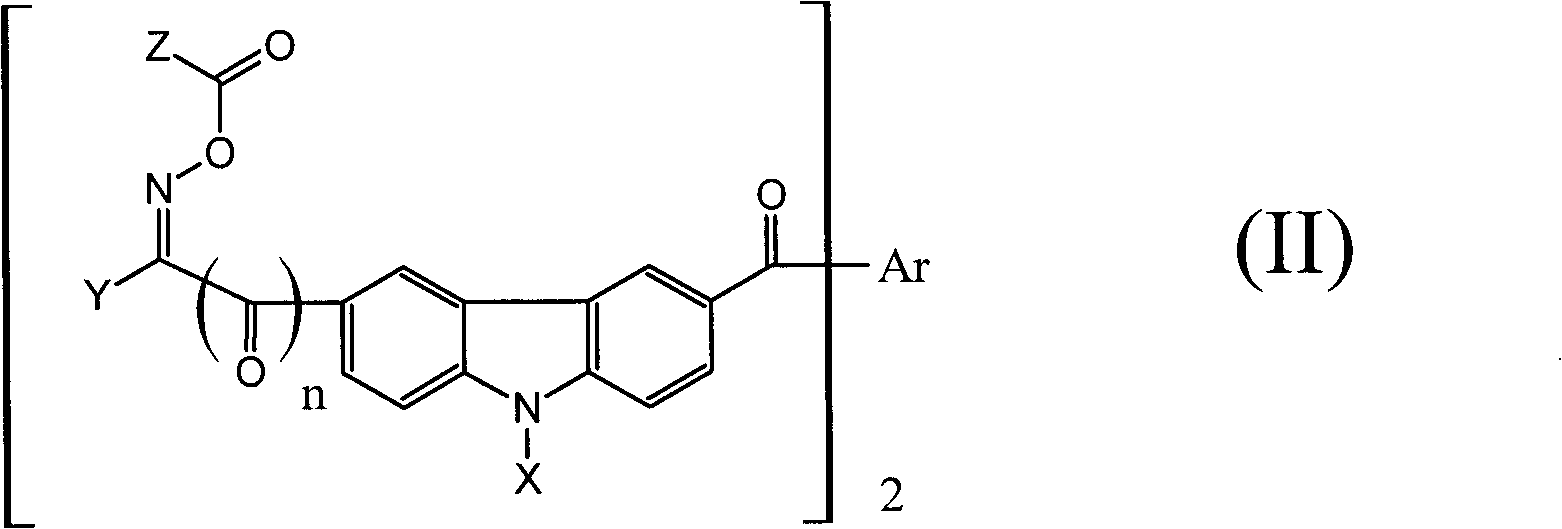

Method used

Image

Examples

Embodiment

[0173] Hereinafter, although an Example and a comparative example are shown and this invention is concretely demonstrated, this invention is not limited to a following example. In addition, the following "parts" and "%" refer to a mass basis unless otherwise specified.

Synthetic example

[0175] (A-1) is equivalent to the synthesis of the resin of aforementioned carboxyl-containing resin (5):

[0176] 2400 g (3 moles) of polycarbonate diol derived from 1,5-pentanediol and 1,6-hexanediol (manufactured by Asahi Kasei Chemicals Corporation, TJ5650J) were charged into a reaction vessel equipped with a stirring device, a thermometer, and a condenser. , number average molecular weight 800), 603 g (4.5 moles) of dimethylolpropionic acid and 238 g (2.6 moles) of 2-hydroxyethyl acrylate as a monohydroxy compound. Then, 1887g (8.5 moles) of isophorone diisocyanate as a polyisocyanate was put in, heated to 60°C while stirring, and then stopped. When the temperature in the reaction vessel began to drop, it was heated again, and the stirring was continued at 80°C. The spectrum confirms the absorption spectrum of the isocyanate group (2280cm -1 ) disappears, the reaction ends. Then, carbitol acetate was added so that the solid content would be 50% by mass. The acid valu...

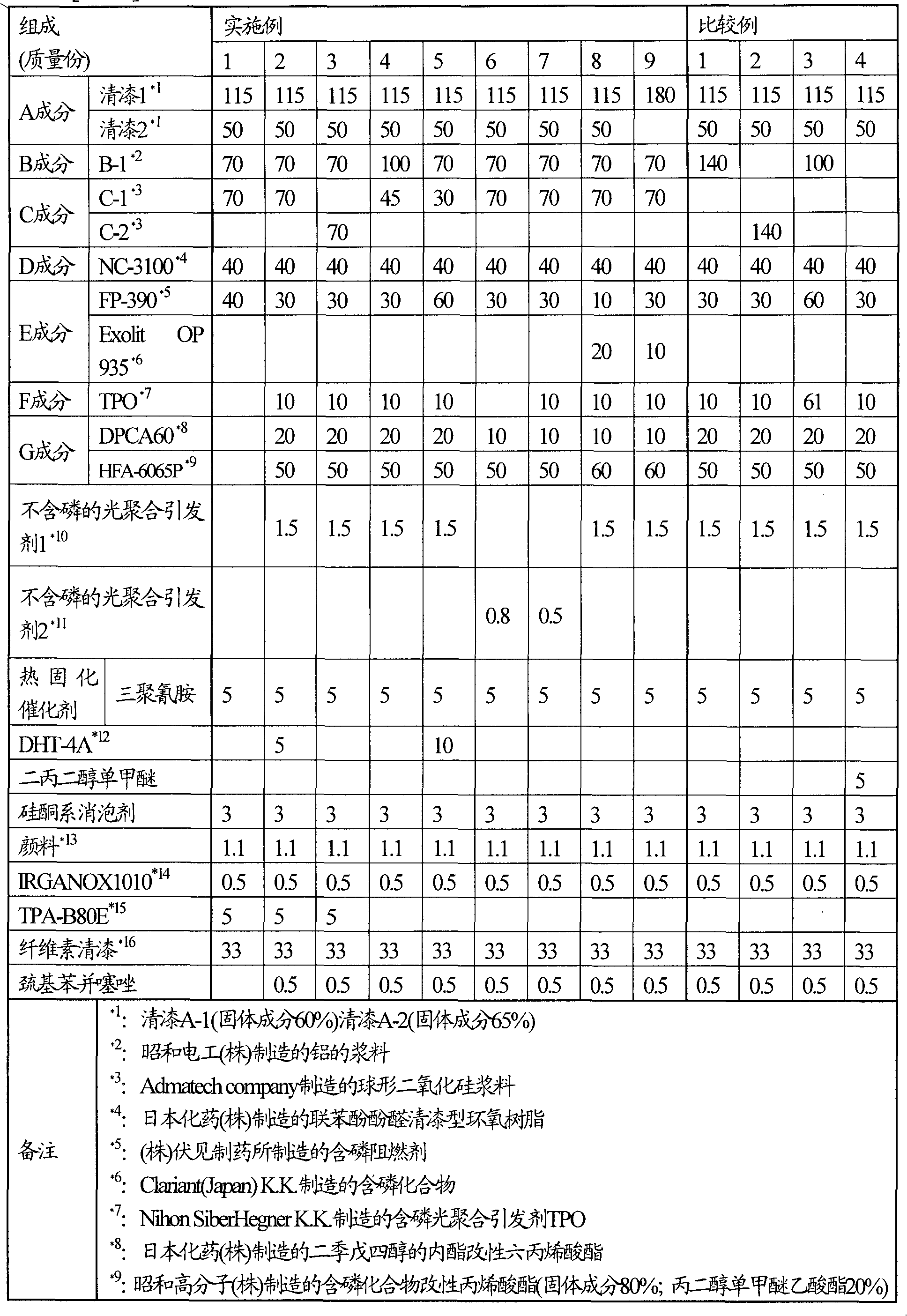

Embodiment 1~9、 comparative example 1~4

[0185] Use the resin solution of above-mentioned synthesis example, mix according to the various compositions shown in Table 1 and the ratio (mass part) shown in Table 1, carry out pre-mixing by agitator, then carry out kneading with 3 roller mills, prepare resistance Solder curable resin composition. Here, the particle size was measured with a particle size analyzer manufactured by ERICHSEN, and the degree of dispersion of the curable resin composition obtained was evaluated to be 15 μm or less.

[0186] [Table 1]

[0187]

[0188]

[0189] Performance evaluation:

[0190] optimal exposure

[0191] A circuit pattern substrate with a copper thickness of 35 μm is ground with a polishing roll, washed with water, dried, and then coated with the thermosetting and photocurable resins of Examples 2 to 9 and Comparative Examples 1 to 4 above by the screen printing method on the entire surface. The composition was dried in a hot air circulation drying oven at 80° C. for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com