Phase-change energy-storage polyurethane foam and preparation method thereof

A polyurethane foam and phase-change energy storage technology, which is applied in the field of phase-change energy storage rigid polyurethane foam and its preparation, can solve the problems of aggravated foam quality reduction, application obstacles, etc., and achieve energy saving, wide application, and fireproof performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

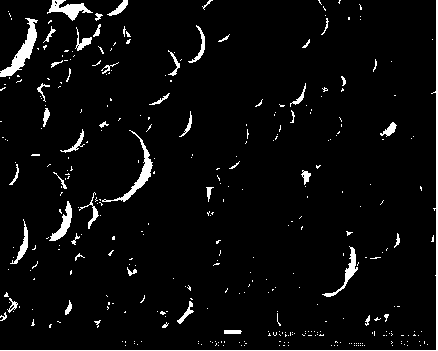

[0038] Using n-octadecane (melting point: 28.5°C, latent heat of phase transition: 242.4kJ / kg) as the capsule core and polyurethane-polysiloxane as the capsule wall, MicroPCMs were prepared according to the in-situ polymerization method, with an average particle size of 5 μm. The latent heat of phase change of MicroPCMs measured by differential scanning calorimetry (DSC) was 105.7 kJ / kg. In the phase change energy storage microcapsules, the organic phase change material accounts for 40% of the weight of the phase change energy storage microcapsules, the amount of the crosslinking agent is 6% of the weight of the phase change energy storage microcapsules, and the polysiloxane is Silica accounts for 10% of the weight of the microcapsule wall.

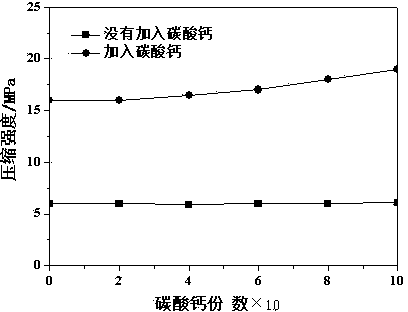

[0039] Using ultrasonic equipment, 60 parts of nano-calcium carbonate (average particle size is 70nm) and 20 parts of MicroPCMs are uniformly dispersed in 150 parts of PAPI, and left for 20h to obtain mixture I, wherein the dispersion ado...

Embodiment 2

[0051] In embodiment 1, 60 parts of nano-calcium carbonates are changed into 50 parts, add 10 parts of red phosphorus simultaneously, all the other materials and operating conditions are constant, obtain sample E. The oxygen index of the polyurethane foam was determined to be 30 by the oxygen index method, indicating that the synergistic flame retardant system of nano-calcium carbonate and red phosphorus has a better flame retardant effect.

Embodiment 3

[0053] In Example 1, the proportion of the organic phase-change material in the weight of the phase-change energy storage microcapsules was increased to 65%, and the remaining materials and operating conditions were kept unchanged to obtain sample F. The phase transition temperature of the polyurethane foam was determined by DSC to be 27.2° C., and the latent heat of phase transition was 79.6 kJ / kg; meanwhile, the oxygen index of the foam was measured to be 24. That is, as the proportion of organic phase change materials increases, the latent heat value of phase change of polyurethane foam increases, while the flame retardancy decreases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com