Halogen-free flame retardant epoxy resin composite and flexible copper clad laminate prepared with same

A technology of epoxy resin and hydantoin epoxy resin, applied in the direction of circuit substrate materials, improvement of metal adhesion of insulating substrates, layered products, etc., can solve the problem of carcinogenic dioxins, unsatisfactory flame retardant effect, substrate Susceptible to heat damage and other issues, to achieve excellent dimensional stability, outstanding corrosion resistance, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

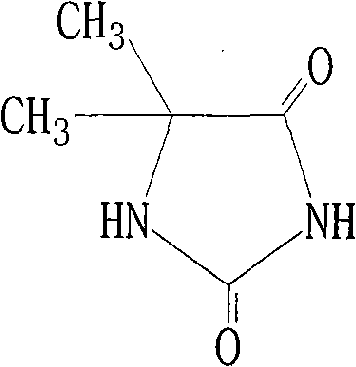

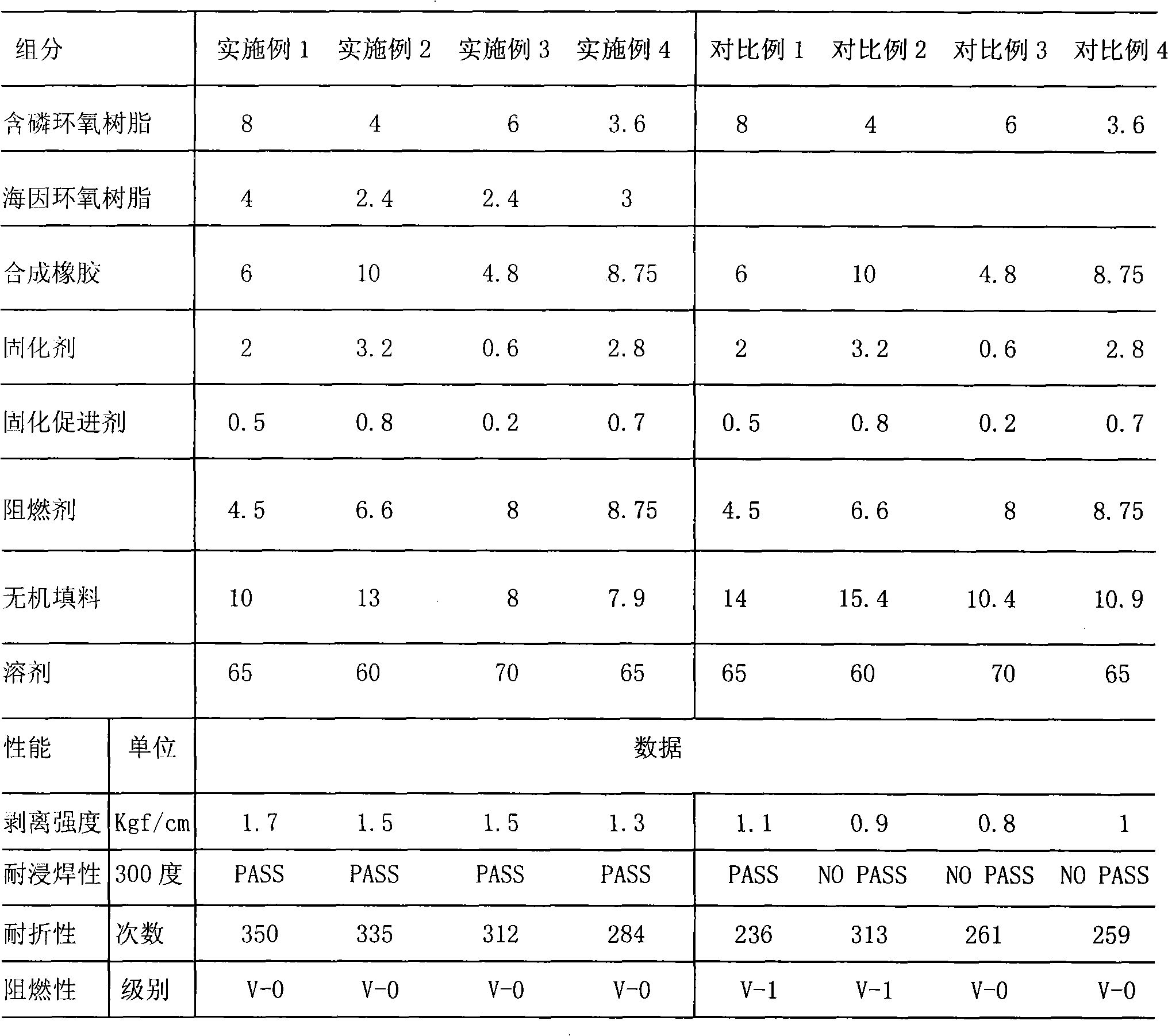

[0034] Halogen-free flame-retardant epoxy resin composition, composed of solid components and organic solvents, the weight of each component is as follows: 8 grams of phosphorus-containing epoxy resin, 6 grams of synthetic rubber, 4 grams of hydantoin epoxy resin, two curing agents 2 grams of cyanamide, 0.5 grams of curing accelerator 2-methylimidazole, 10 grams of inorganic filler aluminum hydroxide, 4.5 grams of flame retardant triphenyl phosphate, and 65 grams of solvent butanone.

[0035] Among the above components, imidazole compounds used as curing accelerators are not particularly limited, and 2-methylimidazole, 1-methylimidazole, 2-ethyl-4-methylimidazole, 1 -cyanoethyl-2-ethyl-4-methylimidazole, 2-phenylimidazole, 2-undecylimidazole, 2-phenyl-4-methylimidazole, these imidazoles can be used alone or in two or in multiple combinations.

[0036] The curing agent contains one or more of dicyandiamide, diaminodiphenylmethane, diaminodiphenylsulfone, phthalic anhydride, me...

Embodiment 2

[0041] The content percentage of each component is as shown in Table 1, and the weight of each component is as follows: 4 grams of phosphorus-containing epoxy resin, 10 grams of synthetic rubber, 2.4 grams of hydantoin epoxy resin, 3.2 grams of curing agent dicyandiamide, and curing accelerator 0.8 grams of 2-phenylimidazole, 13 grams of inorganic filler silicon dioxide, 6.6 grams of flame retardant triphenyl phosphate, and 60 grams of solvent ethanol.

[0042] The thickness of the coating is 30um, the thickness of the polyimide flexible board is 35um, the thickness of the copper foil is 25um, and the rest are the same as in Example 1.

Embodiment 3

[0044] The content percentage of each component is as shown in Table 1, and the weight of each component is as follows, 6 grams of phosphorus-containing epoxy resin, 4.8 grams of synthetic rubber, 2.4 grams of hydantoin epoxy resin, 0.6 grams of curing agent diaminodiphenyl sulfone, curing Accelerator 2-phenylimidazole 0.2 grams, inorganic filler magnesium hydroxide 8 grams, flame retardant tricumyl phosphate 8 grams, solvent ethyl acetate 70 grams.

[0045] The thickness of the coating is 25um, the thickness of the polyimide flexible board is 35um, the thickness of the copper foil is 25um, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com