Injection equipment for blast furnace in metallurgical industry

A blast furnace and industry technology, applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of unbalanced airflow in branch pipes, large airflow resistance loss at elbows, and reduced production efficiency, so as to achieve uniform injection and facilitate airflow balance , the effect of increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

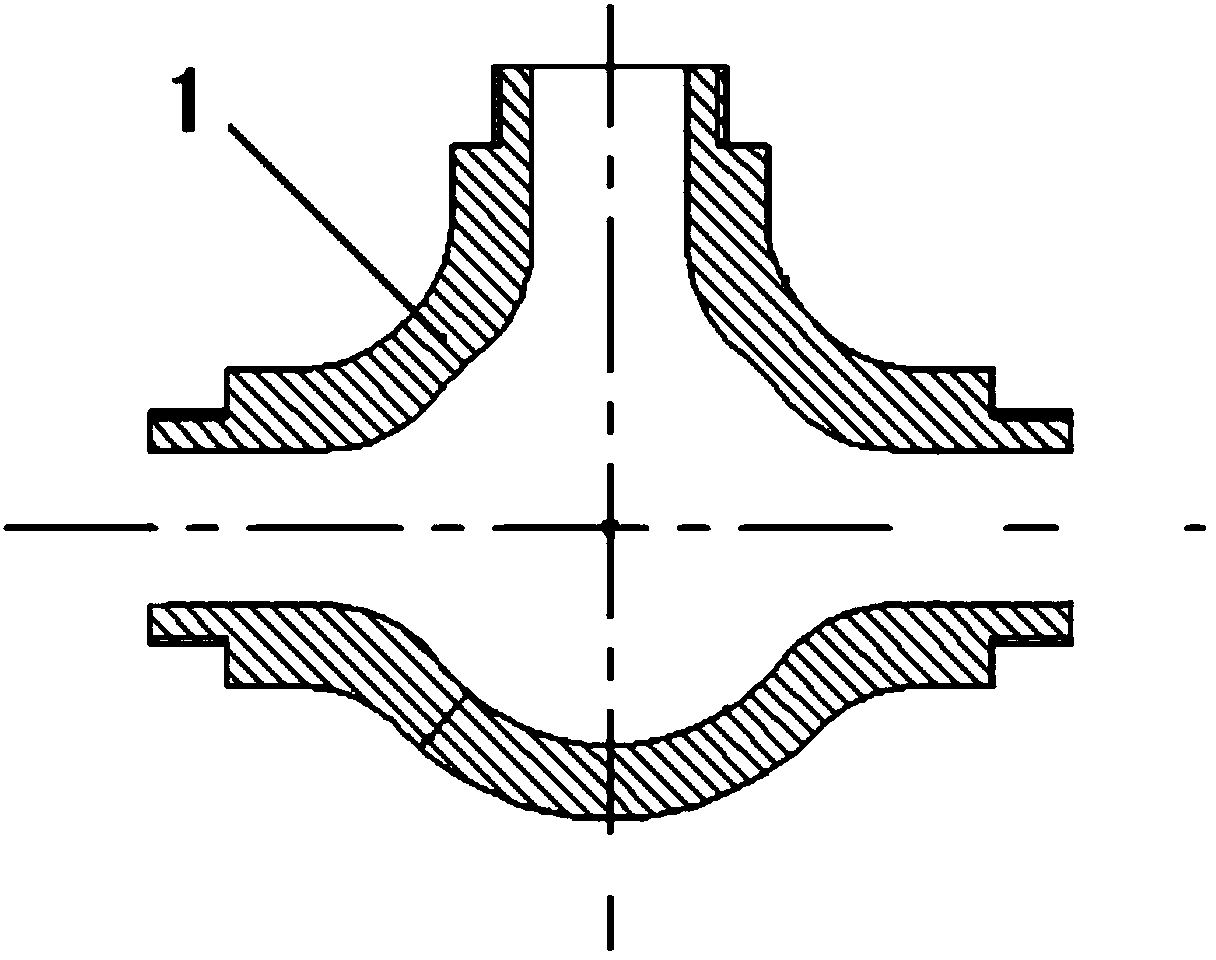

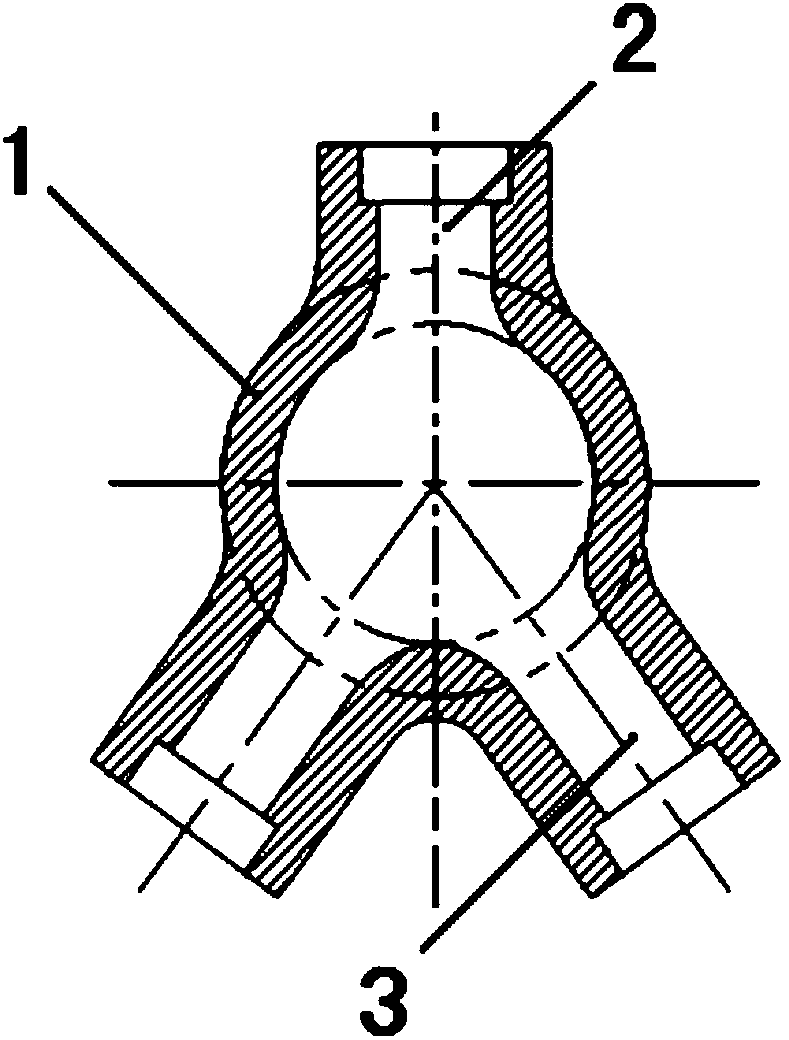

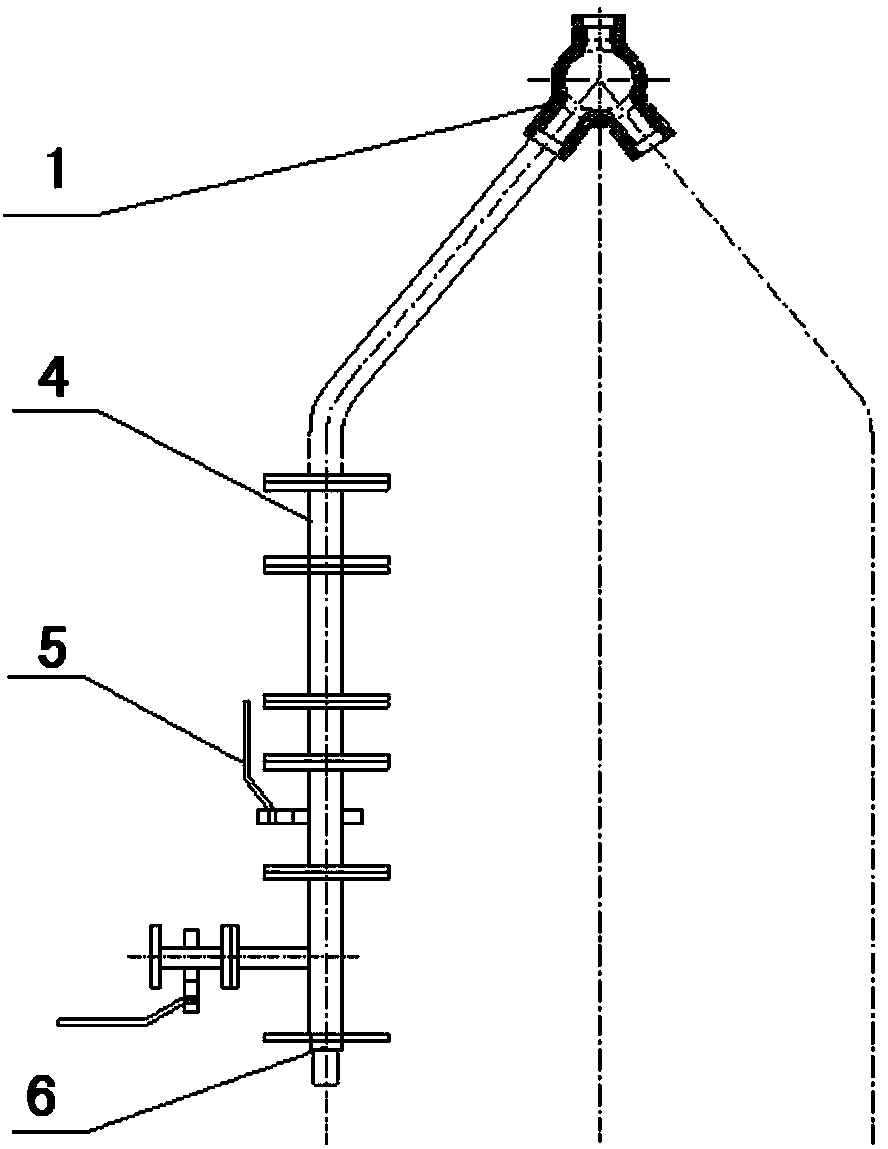

[0023] Such as Figure 1-3 As shown, the technical solution provided by the present invention is a blast furnace injection equipment in the metallurgical industry, including a distributor 1, the distributor 1 includes a main pipe 2 and a branch pipe 3, and the intersection of the main pipe 2 and the branch pipe 3 A spherical cavity is provided, and the included angle between the main pipe 2 and the branch pipe 3 is greater than 90 degrees. The distributor 1 is provided with two branch pipes 3 , and the two branch pipes 3 are respectively arranged on both sides of the central line of the main pipe 2 . The two branch pipes 3 on the distributor 1 are arranged symmetrically. The included angle between the main pipe 2 and the branch pipe 3 is 100-150°. The included angle between the two branch pipes 3 is smaller than the included angle between the main pipe 2 and the branch pipe 3 . The branch pipe 3 includes a restrictor tube 4 , and the restrictor pipe 4 is connected with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com