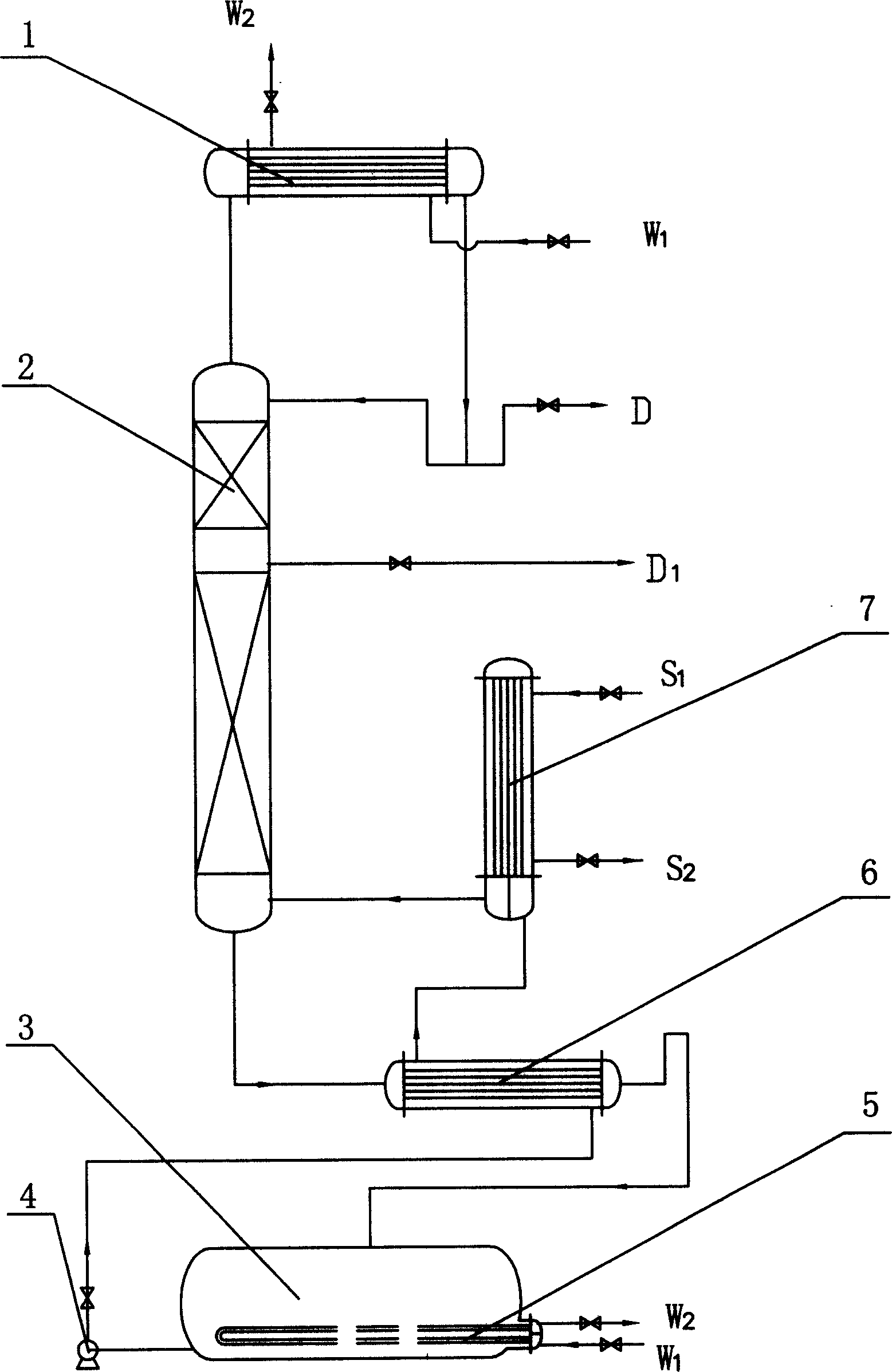

Thermosensitive material intermittent rectifying process having side material output and tower kettle cold material storage

A rectification process and side-line technology, applied in the field of batch rectification process of heat-sensitive materials, can solve the problems of difficult to achieve, decompose, low yield and other problems with ordinary rectification technology, and achieve short rectification time, low thermal decomposition rate, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: The raw material is 91% (mass percentage) dimethylbenzyl orthoacetate. Take appropriate batch of raw material liquid into the tower kettle, turn on the canned motor pump, evaporator, cooler and condenser to start the distillation tower, adjust the flow rate of the cooling water of the cooler, so that the temperature of the material liquid in the tower kettle is not higher than 50℃ . Volatile impurities are concentrated at the top of the tower and extracted from the top of the tower. When the material concentration at the sideline outlet reaches 99.5% (mass percentage), the finished product is extracted from the sideline outlet. When the concentration of distillate at the top outlet reaches When 99.5% (mass percentage), the product is extracted from the top of the tower and the side line at the same time. With the rectification, when the product content of the side line outlet is less than 99% (mass percentage), the side line discharging is stopped, and the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com