Butadiene refining method and butadiene refining device

A refining method and refining device technology, applied in chemical instruments and methods, hydrocarbons, organic chemistry, etc., can solve the problems of inability to use butadiene copolymers, reduce the yield of butadiene, and consume a large amount of circulating water. Achieve significant practicality and economic benefits, reduce device investment and operating costs, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

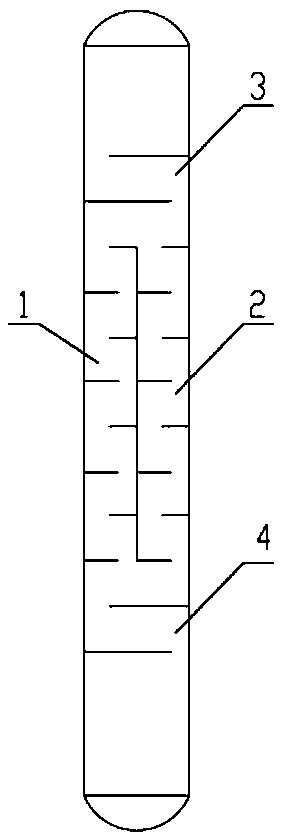

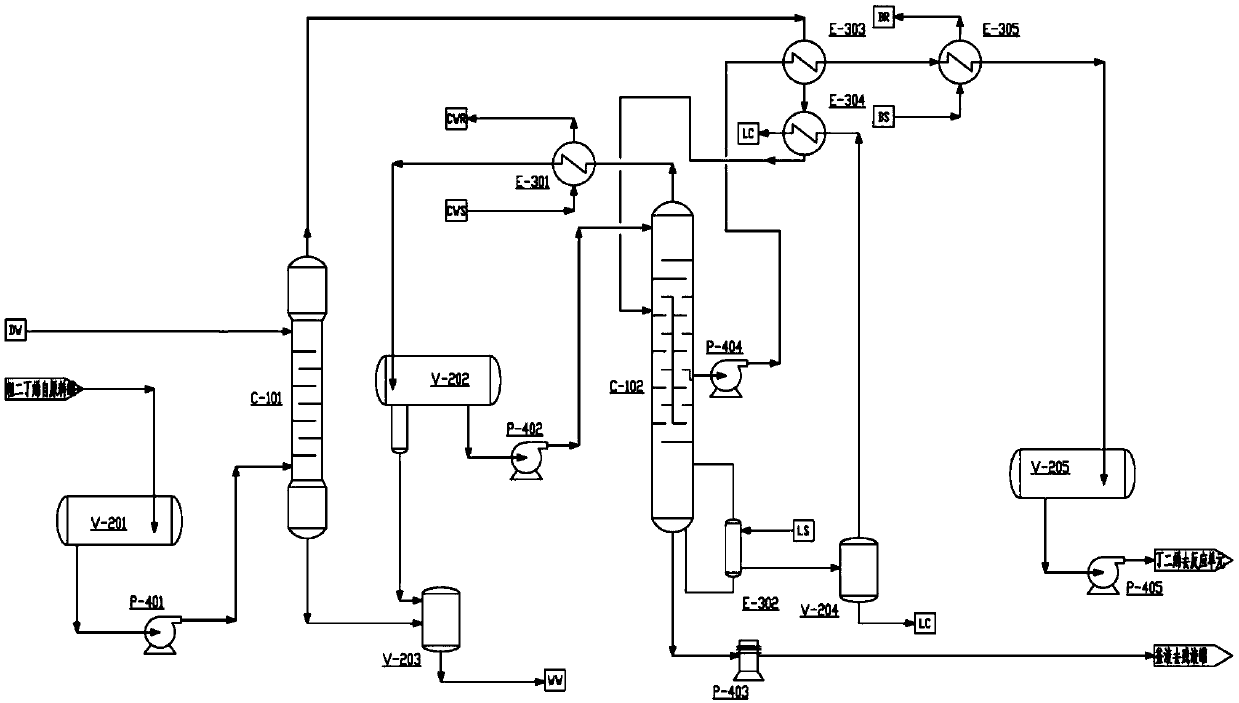

[0032] use figure 2In the process flow shown, the feed rate of crude butene in a plant is 5500kg / h, the feed temperature is 25°C, and the feed pressure is 0.6MPa (absolute pressure). Crude butadiene contains 50ppm p-tert-butylcatechol (TBC), 100ppm water and traces of water-soluble light components (small molecule alcohols and solvents), and the remaining components are butadiene. Crude butadiene is pumped into the bottom of water washing tower C-101 through butadiene buffer tank V-201 by water washing tower feed pump P-401. 100kg / h of process water is fed into the top of the washing tower, and the water temperature is 10°C. The water washing tower is a plate extraction tower with 32 real plates (8 theoretical plates). The wastewater from the water washing tower is discharged into the sewage buffer tank V-203, and the washed crude butadiene is discharged from the top of the water washing tower, which is preheated by the first raw material preheater E-303 and the second raw ...

Embodiment 2

[0037] use figure 2 In the process flow shown, the feed rate of crude butene in a plant is 3300kg / h, the feed temperature is 20°C, and the feed pressure is 0.4MPa (absolute pressure). Crude butadiene contains 30ppm p-tert-butylcatechol (TBC), 50ppm water and traces of water-soluble light components (small molecule alcohols and solvents), and the remaining components are butadiene. Crude butadiene is pumped into the bottom of water washing tower C-101 through butadiene buffer tank V-201 by water washing tower feed pump P-401. 40kg / h of process water is fed into the top of the washing tower, and the water temperature is 5°C. The water washing tower is a plate extraction tower with 24 real plates (6 theoretical plates). The wastewater from the water washing tower is discharged into the sewage buffer tank V-203, and the washed crude butadiene is discharged from the top of the water washing tower, which is preheated by the first raw material preheater E-303 and the second raw ma...

Embodiment 3

[0042] use figure 2 In the process flow shown, the feed rate of crude butene in a plant is 6600kg / h, the feed temperature is 20°C, and the feed pressure is 0.7MPa (absolute pressure). Crude butadiene contains 80ppm p-tert-butylcatechol (TBC), 80ppm water and traces of water-soluble light components (small molecule alcohols and solvents), and the remaining components are butadiene. Crude butadiene is pumped into the bottom of water washing tower C-101 through butadiene buffer tank V-201 by water washing tower feed pump P-401. 130kg / h of process water is fed into the top of the washing tower intermittently, and the water temperature is 18°C. The water washing tower is a packed extraction tower with 10 meters of structured packing (14 theoretical plates). The wastewater from the water washing tower is discharged into the sewage buffer tank V-203, and the washed crude butadiene is discharged from the top of the water washing tower, which is preheated by the first raw material p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com