Method for preparing molecular sieve solid acid catalyst used for preparing ethylene by ethanol dehydration

A solid acid catalyst, ethanol dehydration technology, applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., to achieve the effects of environmental friendliness, non-corrosive equipment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

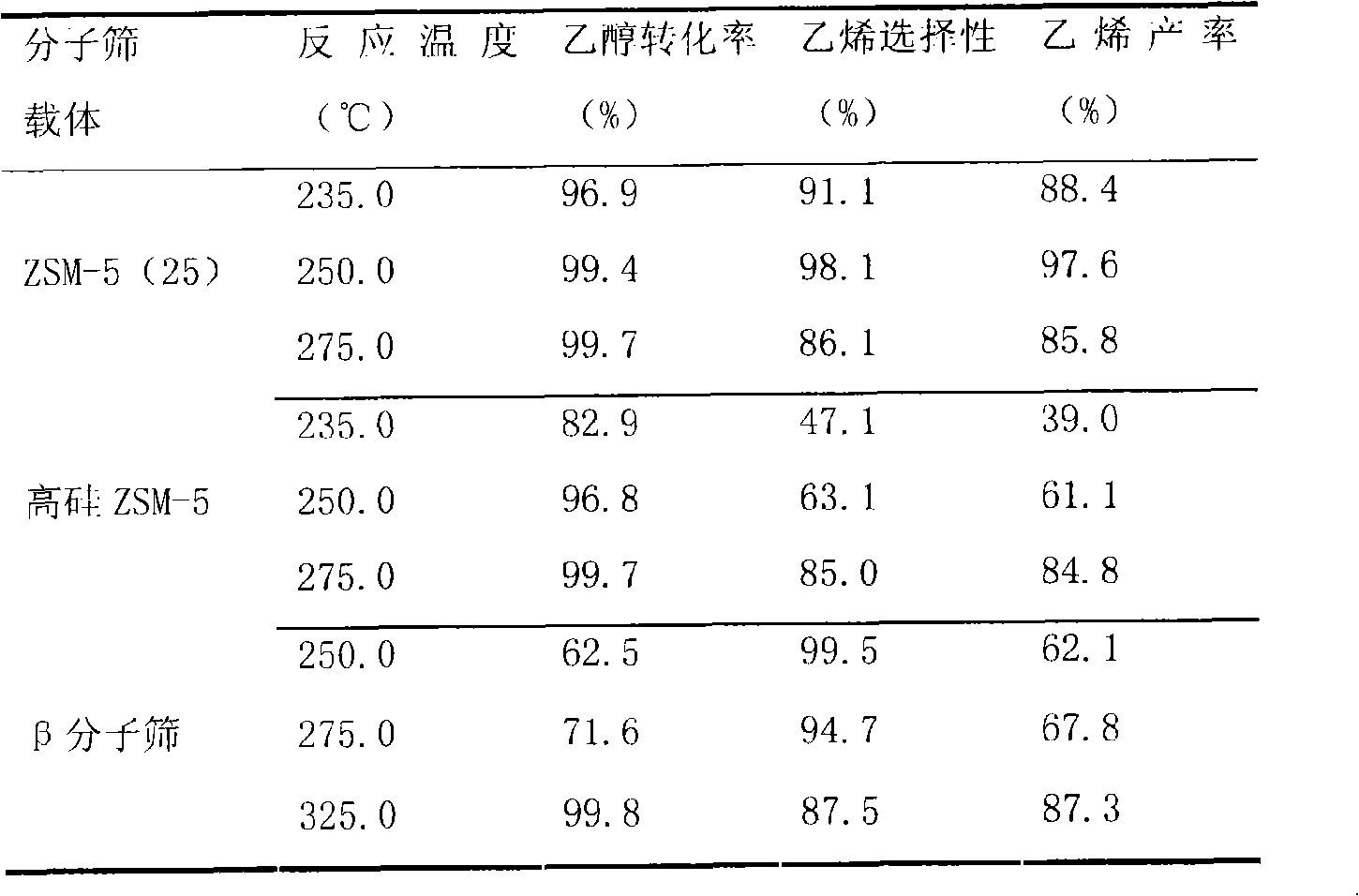

[0020] 10g of hydrogen-type ZSM-5, high-silicon ZSM-5 and beta molecular sieve with a silicon-to-aluminum ratio of 25 were impregnated in Fe with equal volume. 2 (SO 4 ) 3 solution (wherein, according to Fe 2 O 3 The mass ratio with molecular sieve is 10%), immersed at room temperature for 1 h, and then dried at 110 ° C; the dried catalyst was placed in a muffle furnace for pre-calcination for 3 h at a temperature of 350 ° C; Fe-modified catalyst was obtained; Fe-modified catalyst was obtained; Modified molecular sieve with 20ml of H with a concentration of 1mol / L 2 SO 4 The solution was impregnated, treated at room temperature for 30 min, and then dried at 110 °C; the dried catalyst was calcined in a muffle furnace for 3 h at a temperature of 600 °C; molecular sieve supported SO was obtained 4 2- / Fe 2 O 3 Acid catalyst, namely molecular sieve type solid acid catalyst prepared by impregnation method.

[0021] Take 4g of the catalyst prepared above and put it into a s...

Embodiment 2

[0026] In a closed hydrothermal kettle, Fe 2 (SO 4 ) 3 solution (wherein, according to Fe 2 O 3 The mass ratio with ZSM-5 is 15%) equal volume to impregnate 10g hydrogen-type ZSM-5 molecular sieve with a silicon-alumina ratio of 25, and the hydrothermal kettle is heated to 180°C in a closed state, and kept for 12h; then at 110°C After drying, the dried catalyst was calcined in a muffle furnace for 3 h at a temperature of 600 °C; ZSM-5 supported SO was obtained 4 2- / Fe 2 O 3 Acid catalyst, namely molecular sieve type solid acid catalyst prepared by hydrothermal treatment. Take 4g of the catalyst prepared above and load it into a stainless steel fixed-bed tubular reactor for catalytic reaction, the ethanol concentration is 10wt%, and the mass space velocity is 1.3h -1 , and the reaction temperature was 300 °C. Molecular sieve type solid acid catalyst The conversion rate of catalyzing ethanol dehydration to ethylene under this condition is 99.8%, and the selectivity of ...

Embodiment 3

[0028] 10 g of hydrogen-type ZSM-5 molecular sieve with a silicon-alumina ratio of 25 was immersed in Fe(NO) in an equal volume. 3 ) 3 solution (wherein, according to Fe 2 O 3 The mass ratio to molecular sieve is 15wt%), impregnated at room temperature for 1 h, and then dried at 110 ° C; the dried catalyst was placed in a muffle furnace for pre-calcination for 2.5 h at a temperature of 390 ° C; Fe / ZSM-5 modified catalyst was obtained. catalyst; Fe / ZSM-5 modified molecular sieve was used with 20ml H concentration of 1mol / L 2 SO 4 The solution was impregnated, treated at room temperature for 30 min, and then dried at 110 °C; the dried catalyst was calcined in a muffle furnace for 20 h at a temperature of 300 °C; molecular sieve supported SO was obtained 4 2- / Fe 2 O 3 acid catalyst. Take 4g of the catalyst prepared above and load it into a stainless steel fixed-bed tubular reactor for catalytic reaction, the ethanol concentration is 50wt%, and the mass space velocity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com