High-temperature and high-safety non-water electrolyte

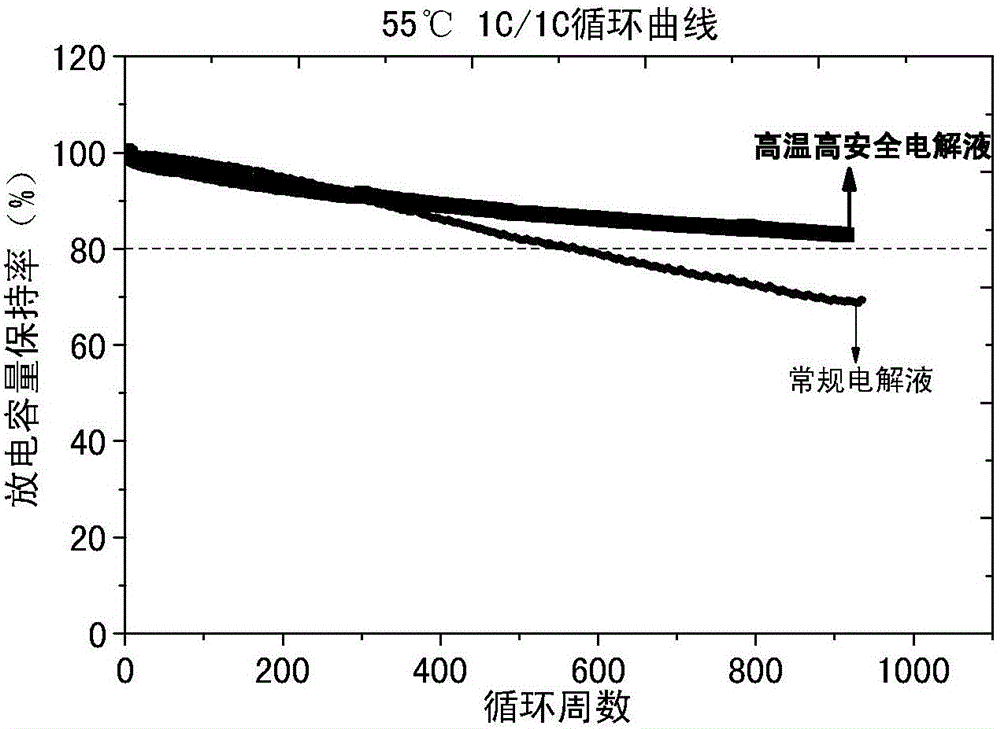

A non-aqueous electrolyte, high-temperature technology, applied in non-aqueous electrolytes, organic electrolytes, circuits, etc., can solve the problems that the high-temperature cycle performance and safety performance of batteries have not been researched, so as to improve cycle life and safety performance, improve Thermal stability, effect of reducing thermal decomposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

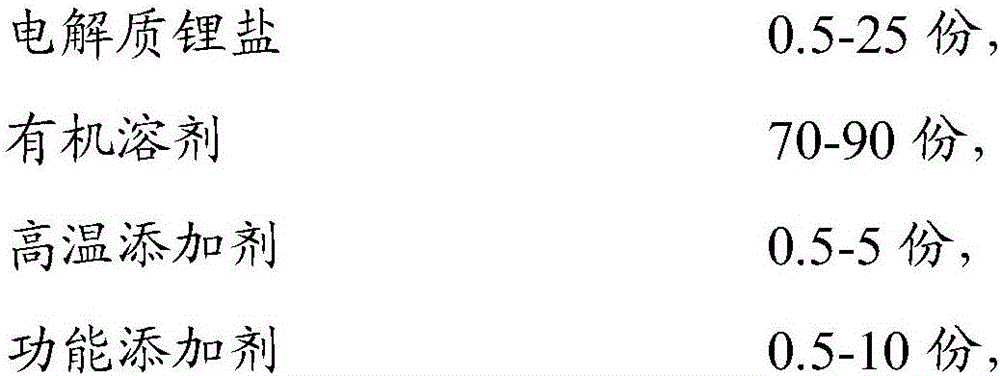

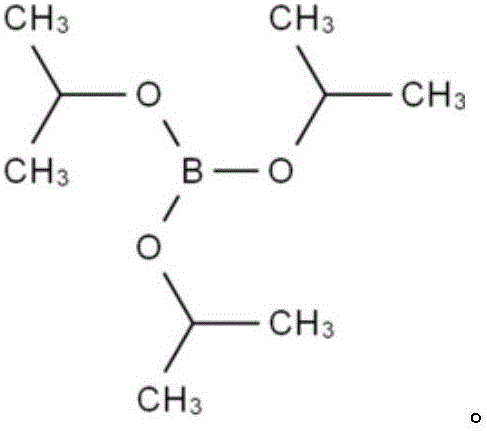

[0023] Embodiment 1, this embodiment provides a high temperature and high safety non-aqueous electrolyte, each component and its content are as follows: Lithium salt is LiPF 6 , the concentration in the electrolyte is 1.0mol / L, the solvent is EC:DEC:EMC=1:1:1 (volume ratio), the additive is VC, which accounts for 1% of the total mass of the electrolyte, and triisopropyl borate accounts for 1% of the total mass of the electrolyte. 1% of the total mass of the electrolyte, and methyl fluorosulfonyl difluoroacetate accounts for 1% of the total mass of the electrolyte.

Embodiment 2

[0024] Embodiment 2, this embodiment provides a high temperature and high safety non-aqueous electrolyte, each component and its content are as follows: Lithium salt is LiPF 6 , the concentration in the electrolyte is 1.0mol / L, the solvent is EC:DEC:EMC=1:1:1 (volume ratio), the additive is VC, which accounts for 1% of the total mass of the electrolyte, and triisopropyl borate accounts for 1% of the total mass of the electrolyte. 1% of the total mass of the electrolyte, and methyl fluorosulfonyl difluoroacetate accounts for 3% of the total mass of the electrolyte.

Embodiment 3

[0025] Embodiment 3, this embodiment provides a high temperature and high safety non-aqueous electrolyte, each component and its content are as follows: Lithium salt is LiPF 6 , the concentration in the electrolyte is 1.0mol / L, the solvent is EC:DEC:EMC=1:1:1 (volume ratio), the additive is VC, which accounts for 1% of the total mass of the electrolyte, and triisopropyl borate accounts for 1% of the total mass of the electrolyte. 1% of the total mass of the electrolyte, and methyl fluorosulfonyl difluoroacetate accounts for 5% of the total mass of the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com