Low-foam nonionic surfactant, preparation method therefor and application of low-foam nonionic surfactant

A non-ionic surface and active agent technology, applied in the direction of surface active detergent composition, polymer surface active compound, chemical equipment and methods, etc., can solve the problem of low product yield, achieve low foam, excellent emulsification, The effect of fast defoaming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

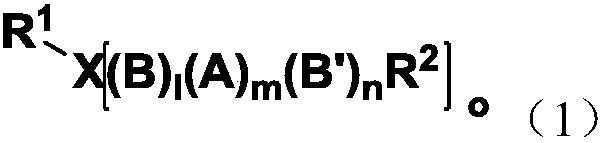

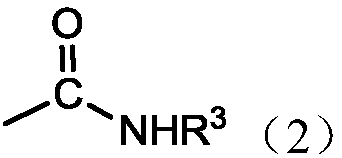

Method used

Image

Examples

Embodiment 1

[0053] (1) Put starter C into the reactor 8-10 100g of straight-chain aliphatic alcohol is reacted with 168g propylene oxide (PO) under the effect of 1.2gKOH as catalyst at a reaction temperature of 100°C and a reactor pressure of 60Psi;

[0054] (2) Raise the reaction temperature to 120° C., keep the pressure constant and the catalyst constant, and react the polyether obtained in step (1) with 418 g of ethylene oxide (EO) to generate intermediate I;

[0055] (3) At a reaction temperature of 100°C, add 70g of butyl isocyanate and 0.35g of stannous octoate catalyst to 186g of intermediate I under normal pressure, then raise the temperature to 120°C and keep it warm for 8 hours to obtain a low-foaming nonionic Surfactant FCB01P.

[0056]

[0057] R 1 for C 8 straight chain alcohol or C 10 The alkane moiety of a straight chain alcohol.

Embodiment 2

[0059] (1) In the reactor, drop into initiator 60g isooctyl alcohol and 40g 2-ethylhexanol, be 100 ℃ at reaction temperature, reactor pressure is 60Psi, under the effect of 1.7gKOH as catalyst, with 186g propylene oxide (PO) response;

[0060] (2) Raise the reaction temperature to 120° C., keep the pressure constant and the catalyst constant, and react the polyether obtained in step (1) with 435 g of ethylene oxide (EO) to generate intermediate I;

[0061] (3) At a reaction temperature of 80°C, add 90g of cyclohexyl isocyanate and 0.60g of bismuth isooctanoate catalyst to 158g of intermediate I under normal pressure, then raise the temperature to 120°C and keep it warm for 6 hours to obtain a low-foaming nonionic Surfactant FCB02D.

[0062]

[0063] R 1 is the alkane moiety of isooctyl alcohol or 2-ethylhexanol.

Embodiment 3

[0065] (1) Put starter C into the reactor 8-10 100g of straight-chain aliphatic alcohol reacts with 174g of ethylene oxide (EO) at a reaction temperature of 120°C, a reactor pressure of 60Psi, and 1.4gKOH as a catalyst;

[0066] (2) Elevate the reaction temperature to 160° C., keep the pressure constant and the catalyst constant, and react the polyether obtained in step (1) with 100 g of ethylene oxide (BO) to generate intermediate I;

[0067] (3) Keeping the reaction temperature at 160° C., the pressure constant, and the catalyst constant, the polyether obtained in step (2) reacts with 174 g of ethylene oxide (EO) to generate intermediate II;

[0068] (4) At a reaction temperature of 90°C, add 130g of phenylisocyanate and 0.54g of stannous octoate catalyst to 180g of intermediate II under normal pressure, then raise the temperature to 130°C and keep it warm for 4 hours to obtain a low-foaming nonionic Surfactant FCB01F.

[0069]

[0070] R 1 for C 8 straight chain alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com