Collector for floating ilmenite and preparation method thereof

A collector and ilmenite technology, which is applied to the collector for flotation and the field of preparation thereof, can solve the problems of adverse effects on ecology and environmental protection, low recovery rate, narrow pH value range, etc., and achieves the preparation method and use. Simple method, reduced dosage, rich foam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

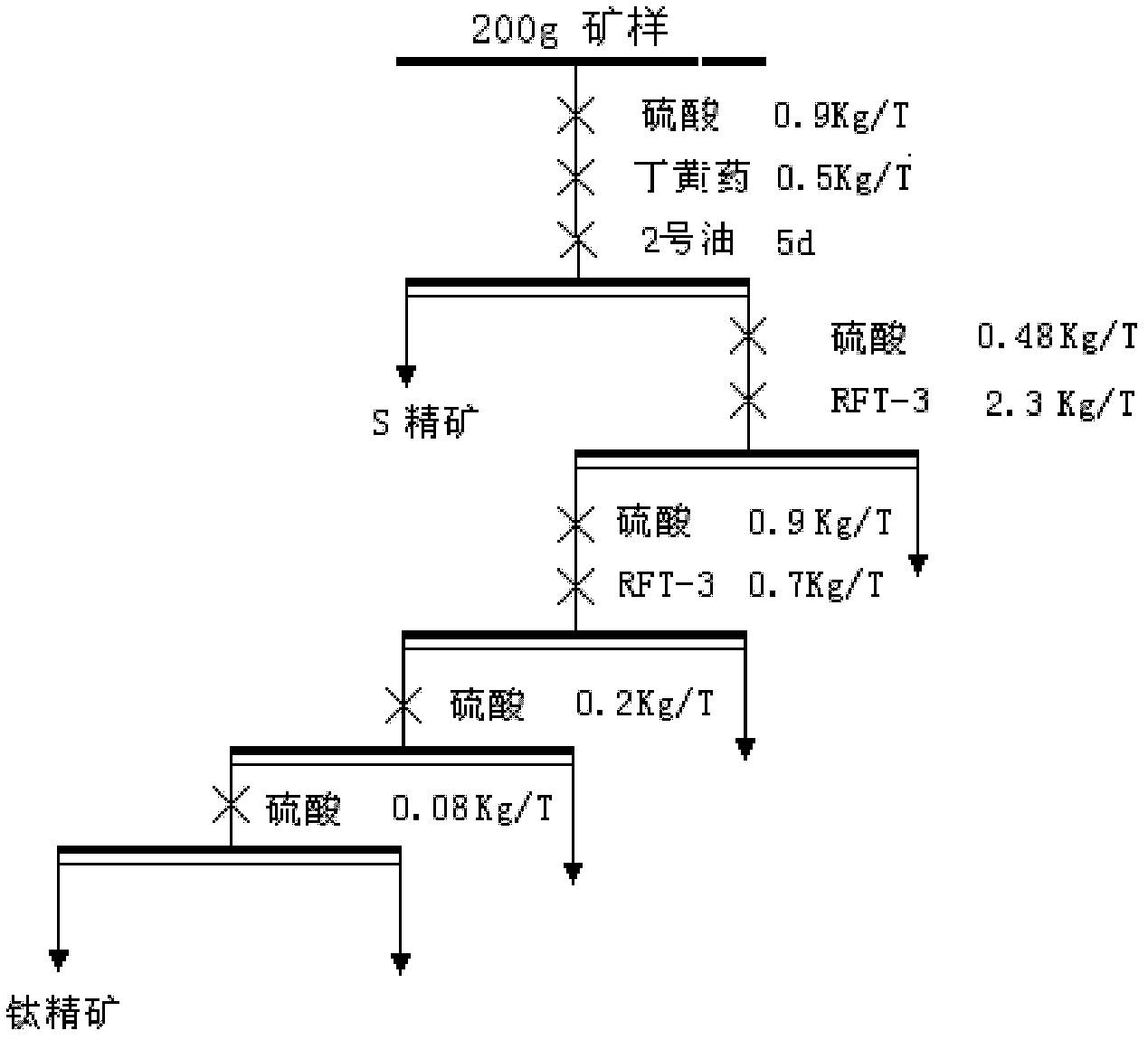

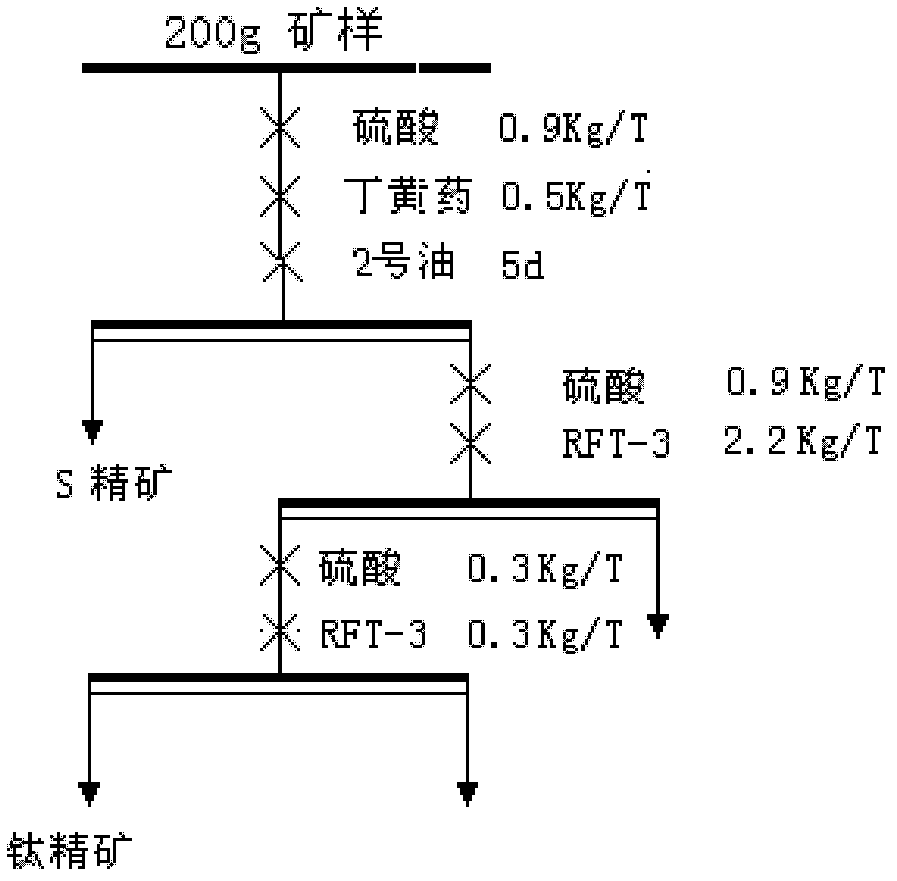

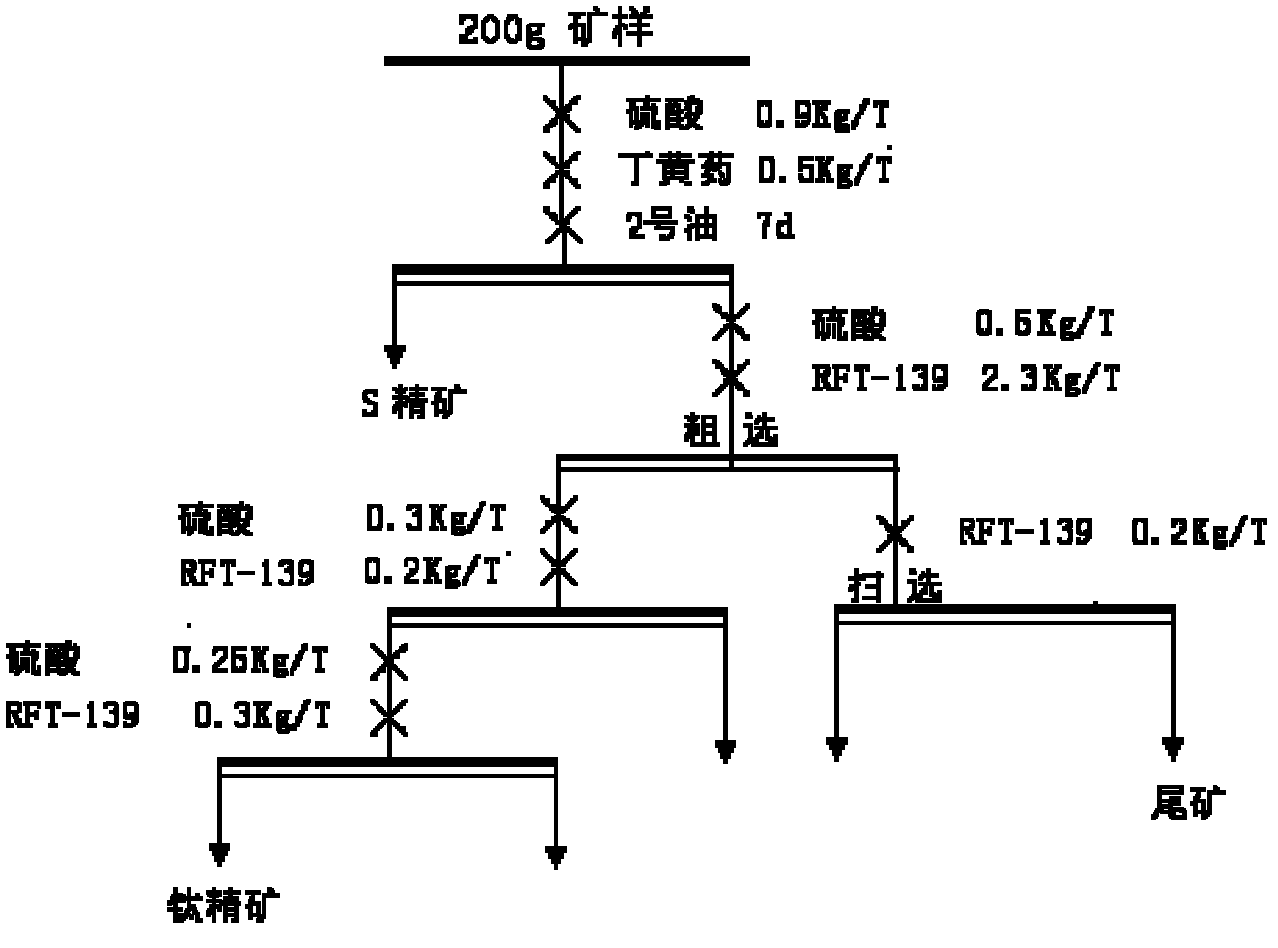

Method used

Image

Examples

Embodiment 1

[0023] A kind of collector of flotation ilmenite of the present invention, it is mainly formulated by the component of following mass fraction:

[0024] Sodium Peroxylate 25%

[0025] Sodium Linoleate Peroxide 15%

[0026] Emulsifier OP-105%

[0027] Tween - 808%

[0028] Kerosene 10% and

[0029] remaining water.

[0030] The components according to the above-mentioned mass fraction ratio were mixed evenly and put into the reaction kettle, and the collector of this example was obtained after stirring for 0.5 h.

Embodiment 2

[0032] A kind of collector of flotation ilmenite of the present invention, it is mainly formulated by the component of following mass fraction:

[0033] Sodium Peroxypalmitate 25%

[0034] Sodium Benzoate Peroxide 35%

[0035] Emulsifier OP-108%

[0036] Spann - 805%

[0037] Diesel 12% and

[0038] remaining water.

[0039] The components according to the above-mentioned mass fraction ratio were mixed evenly and put into the reaction kettle, and the collector of this example was obtained after stirring for 1 hour.

Embodiment 3

[0041] A kind of collector (RFT-3) of flotation ilmenite of the present invention, it is mainly formulated by the component of following mass fraction:

[0042] Sodium peroxylinoleate 50%

[0043] Sodium Benzoate Peroxide 10%

[0044] Emulsifier calcium dodecylbenzenesulfonate 7%

[0045] Tween - 805%

[0046] Spann - 803%

[0047] Kerosene 12% and

[0048] remaining water.

[0049] The components according to the above-mentioned mass fraction ratio were mixed evenly and put into the reaction kettle, and the collector of this example was obtained after stirring for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com