Preparation method of alkoxy end capping silicone oil

An alkoxy-terminated and alkoxysilane technology, which is applied in the field of preparation of alkoxy-terminated silicone oil, can solve the problems of cumbersome process, poor product storage stability, difficulty in removing hydrogen chloride, etc., and achieves a simple reaction route and stable product. The effect of good performance and high end capping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of alkoxy-terminated silicone oil comprises the following steps:

[0019] a. Under the protection of nitrogen, add a catalyst to the high-viscosity hydroxyl-terminated polydimethylsiloxane and alkoxysilane, raise the temperature to 80-130°C, and react for 1-6 hours;

[0020] b. After the reaction is completed, add a neutralizing agent to neutralize to neutrality;

[0021] c, filter the filtrate, and the filtrate is the crude product of alkoxy-terminated silicone oil;

[0022] d. Distill the crude product at 120-170°C under a pressure of -0.06--0.09 MPa to obtain alkoxy-terminated silicone oil.

[0023] Wherein, in the step a of the preparation method of the above-mentioned alkoxy-terminated silicone oil, the alkoxysilane is tetramethoxysilane, methyltrimethoxysilane, methyltriethoxysilane, vinyltrimethoxysilane Any one of base silane and vinyl triethoxy silane.

[0024] Wherein, in step a of the above method, the viscosity of the high-viscosity...

Embodiment 1

[0035] Put 100 parts of high-viscosity hydroxyl-terminated polydimethylsiloxane and 2 parts of vinyltrimethoxysilane into the reaction kettle, open the nitrogen protection device to feed nitrogen into the reaction kettle, and add 100ppm of potassium siloxane alkoxide catalyst , heated up to 110°C, and reacted for 5 hours. Add a phosphoric acid neutralizing agent in an equimolar ratio to the catalyst, neutralize the product to neutrality, filter the product in a filter device, and place the filtered product in a reaction kettle at -0.09MPa, 150°C Under low boiling conditions, the low boilers were removed by distillation to obtain a colorless, transparent, low-viscosity alkoxy-terminated silicone oil. Product viscosity is 300mPa. s, the refractive index is 1.44.

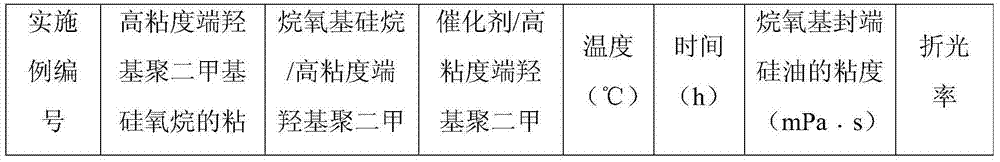

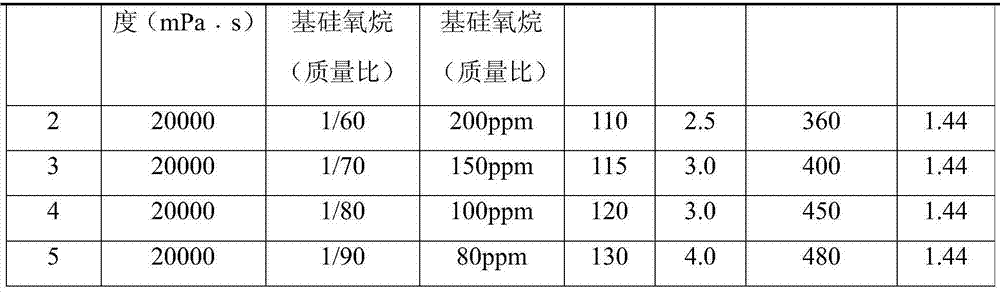

Embodiment 2~5

[0037] The specific raw materials and operation steps of Examples 2 to 5 are the same as those of Example 1, the difference lies in the ratio of materials, see Table 2 for specific data, and the ratio of materials and output of each embodiment are by weight.

[0038] Table 2

[0039]

[0040]

[0041] According to the data in Table 2, it can be seen that in the formulas of the above examples, the viscosity of the product is directly related to the ratio of the end-capping agent alkoxysilane, and the amount of the catalyst only has an impact on the reaction rate, and has no effect on the final viscosity of the product. Has little effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com