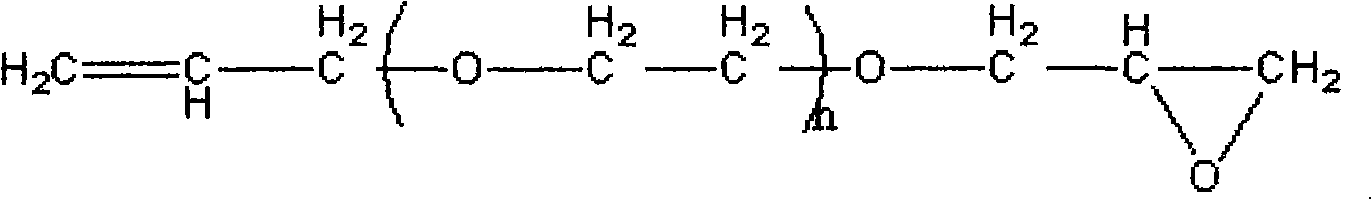

Method for preparing glycidol ether terminated propenol polyoxyethylene ether

A technology of terminal allyl alcohol polyoxyethylene ether and terminal allyl polyoxyethylene ether, which is applied in the field of preparation of end-capped polyether, and can solve the problem of many intermediate by-products, affecting product yield, and epoxy group ring-opening. Addition side reactions and other problems, to achieve the effect of high reactivity, convenient and fast purification, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

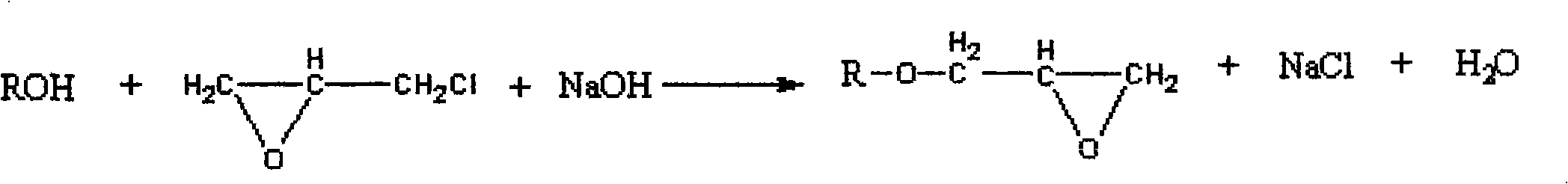

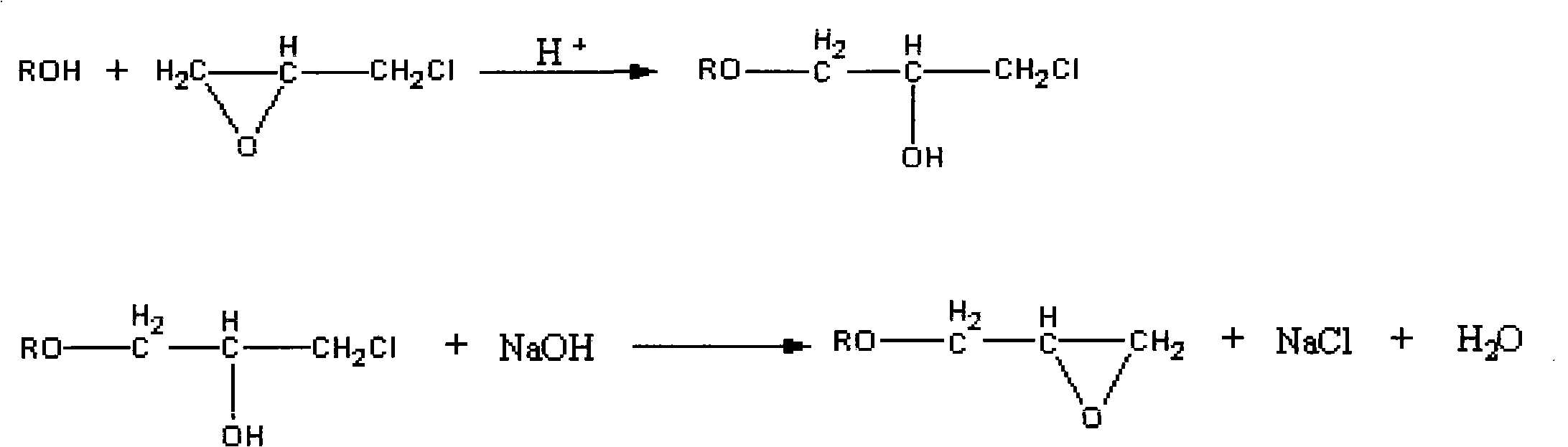

Method used

Image

Examples

Embodiment 1

[0046] In thermometers, condensers, stirrers, N 2 Add 454.8 g of allyl polyoxyethylene ether (produced by Zhejiang Huangma Chemical Group Co., Ltd., molecular weight 454) into the 1000 mL dry four-neck flask at the entrance, vacuum dehydrate at 100 ° C for 30 min, and when the temperature drops to 80 ° C, add the catalyst NaH1. 6g. Add 101.8 g of epichlorohydrin dropwise with a constant pressure dropping funnel for 2 hours. After the addition, continue the reaction for 2 hours. Control the reaction temperature at 80° C. and remove excess epichlorohydrin under reduced pressure. Weigh 40.2g of NaOH and dissolve it in deionized water to form a 40% aqueous solution, add it dropwise to the intermediate of allyl polyoxyethylene chlorohydrin ether, and add it for 2 hours. The reaction was continued for 2 hours. After the reaction was finished, impurities were removed by post-processing such as vacuum distillation and filtration to obtain a capped polyether product. The measured epo...

Embodiment 2

[0048] In thermometers, condensers, stirrers, N 2Add 430.8 g of allyl polyoxyethylene ether (produced by Zhejiang Huangma Chemical Group Co., Ltd., molecular weight 718) into the 1000 mL dry four-neck flask at the entrance, vacuum dehydrate at 100 ° C for 30 min, and when the temperature drops to 70 ° C, add the catalyst NaH2. 0g. Add 66.6 g of epichlorohydrin dropwise with a constant-pressure dropping funnel for 1 hour, and continue the reaction for 3 hours after the addition is complete. Control the reaction temperature at 70° C., and remove excess epichlorohydrin under reduced pressure. Weigh 28.8g of NaOH and dissolve it in deionized water to form a 30% aqueous solution, add it dropwise to the intermediate of allyl polyoxyethylene chlorohydrin ether, the time of adding is 1 hour, control the reaction temperature at 30°C, and the addition is completed The reaction was continued for 3 hours, and after the reaction was completed, after the reaction, the impurities were remov...

Embodiment 3

[0050] In thermometers, condensers, stirrers, N 2 Add allyl polyoxyethylene ether (produced by Zhejiang Huangma Chemical Group Co., Ltd., molecular weight 1158) 463.2g into the 1000mL dry four-necked flask at the entrance, vacuum dehydrate at 100°C for 30min, and when the temperature drops to 55°C, add the catalyst NaH2. 5g. Add 48.1 g of epichlorohydrin dropwise with a constant pressure dropping funnel for 3 hours. After the addition, continue the reaction for 1 hour. Control the reaction temperature at 55° C. and remove excess epichlorohydrin under reduced pressure. Weigh 30.2g of KOH and dissolve it in deionized water to form a 40% aqueous solution, and add it dropwise to the intermediate of allyl polyoxyethylene chlorohydrin ether. The dropping time is 3 hours, and the reaction temperature is controlled at 45°C. The reaction was continued for 1 hour. After the reaction was finished, impurities were removed by post-processing such as vacuum distillation and filtration to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com