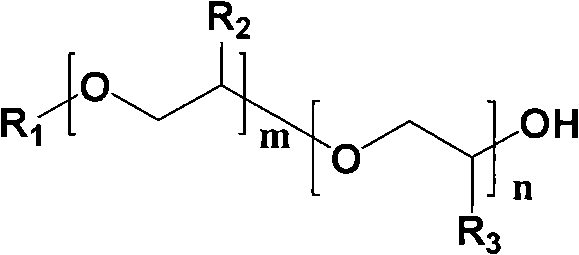

Secondary terminating method for synthesizing methoxy-terminated polyether with high terminating rate

A technology of methoxy capping and capping rate, which is applied in the field of secondary capping method to synthesize high capping rate methoxy capped polyether, which can solve the problems of low capping rate, increased alkali dosage, unsuitable use, etc. , to achieve the effect of increasing the sealing rate and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

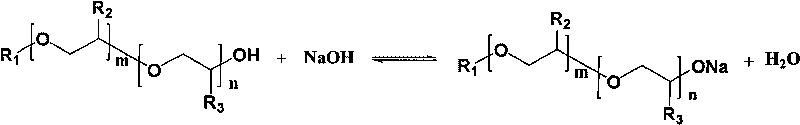

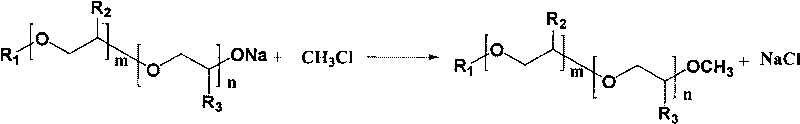

Method used

Image

Examples

Embodiment 1

[0041] Add 600g of polypropylene oxide-ethylene oxide mono-n-butanol ether with a molecular weight of 1210 into a 1L autoclave, gradually raise the temperature to 110°C~120°C through the jacket, and dehydrate under vacuum (0.095MPa~0.099MPa) 1 hour, then lower the temperature to 30°C, add 32g of sodium methoxide into the kettle, then raise the temperature to 110°C~120°C, demethanolize under 0.095MPa~0.099MPa vacuum for 1 hour, cool down to 70°C~80°C, and introduce 32g Chloromethane, control the pressure in the kettle to 0.2-0.4MPa, age for 5 hours, add 6.9g sodium hydride (50% active ingredient) after venting, degas for 1 hour under the same conditions as before, then press 8g of methyl chloride, The pressure is 0.2MPa. When the pressure in the kettle drops to 0.1MPa, the temperature is lowered to 30°C and the material is discharged. After the feed liquid is post-treated, 550g of methoxy-terminated polypropylene oxide-ethylene oxide mono-n-butanol ether is obtained. The value ...

Embodiment 2

[0043] Add 600g of polypropylene oxide-ethylene oxide mono-n-butanol ether with a molecular weight of 1112 into a 1L autoclave, gradually raise the temperature to 110°C~120°C with steam through the jacket, and dehydrate under vacuum (0.095MPa~0.099MPa) 1 hour, then lower the temperature to 30°C, add 25.9g of sodium hydroxide into the kettle, then raise the temperature to 110°C~120°C, dehydrate under 0.095MPa~0.099MPa vacuum for 1 hour, cool down to 70°C~80°C, pass 36g of methyl chloride, control the pressure in the kettle to 0.2-0.4MPa, age for 5 hours, add 7.51g of sodium hydride (50% active ingredient) after venting, degas for 1 hour under the same conditions as before, and then press 9g of methyl chloride into the kettle. The internal pressure is 0.2MPa. When the pressure in the kettle drops below 0.1MPa, the temperature is lowered to 30°C and the material is discharged. The material liquid is post-treated to obtain 547g of methoxy-terminated polypropylene oxide-ethylene oxi...

Embodiment 3

[0045]Add 600g of polypropylene oxide-ethylene oxide monoethanol ether with a molecular weight of 1305 into a 1L autoclave, gradually raise the temperature to 110°C~120°C through the jacket, and dehydrate under vacuum (0.095MPa~0.099MPa) for 1 hour , then lower the temperature to 30°C, add 30.9g of potassium hydroxide to the kettle, then raise the temperature to 110°C to 120°C, dehydrate under vacuum at 0.095MPa to 0.099MPa for 1 hour, cool down to 70°C to 80°C, and introduce 30g of chlorine Methane, control the pressure in the kettle to 0.2-0.4MPa, age for 5 hours, add 6.4g sodium hydride (50% active ingredient) after venting, degas for 1 hour under the same conditions as before, then press 7g of methyl chloride, the pressure in the kettle 0.2MPa, when the pressure in the kettle drops below 0.1MPa, the temperature is lowered to 30°C and the material is discharged, and the material liquid is post-treated to obtain 542g of methoxy-terminated polypropylene oxide-ethylene oxide mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com