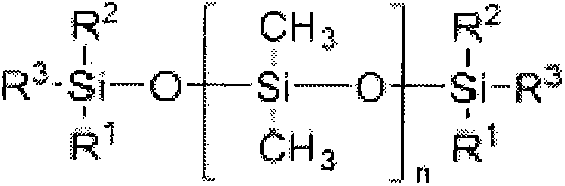

A kind of alkoxy terminated polysiloxane polymer and preparation method thereof

A technology of alkoxy-terminated and hydroxyl polydimethylsiloxane, which is applied in the direction of adhesives, etc., can solve problems such as production troubles, damage to processing performance, and viscosity peaks, and achieve simple and stable production processes and difficult neutralization , the effect of high capping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

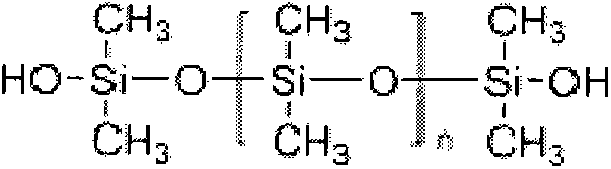

[0025] Catalyst preparation: At room temperature, 1 mol of dibutylamine and 1 mol of acetic acid were subjected to a salt-forming reaction in a flask for 1 hour to prepare dibutylamine acetate.

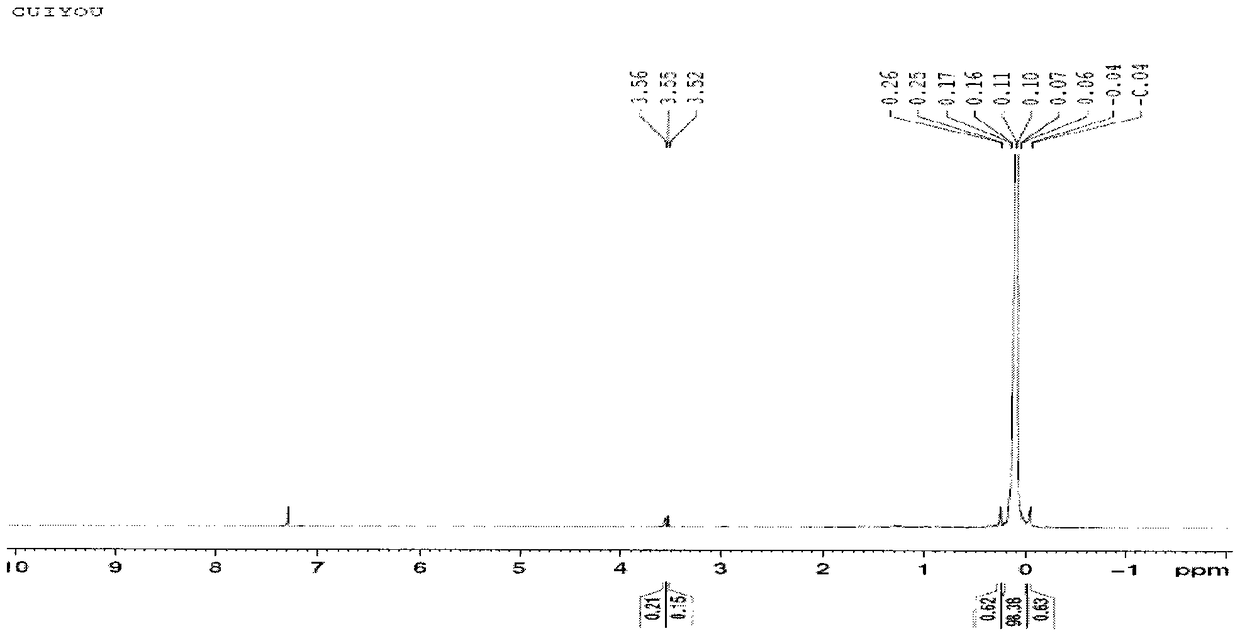

[0026] Preparation of alkoxy-terminated polymer: Add 100 parts of α, ω-dihydroxypolydimethylsiloxane and 1 part of methyltrimethoxysilane into the reaction kettle, and stir to raise the temperature to 60 At about ℃, add 0.05 part of the above-mentioned dibutylamine acetate, keep it warm for about 3 hours, heat up to 110 ℃, distill at a vacuum degree of ≥0.09MPa for 1 hour, remove low molecular weight, and obtain alkoxy-terminated polysiloxane Polymer, product performance test results are shown in Table 1.

Embodiment 2

[0028] Catalyst preparation: 1 mol of isopropylamine and 1 mol of formic acid were subjected to a salt-forming reaction in a flask at room temperature for 3 hours to prepare isopropylamine formate.

[0029] Preparation of alkoxy-terminated polymer: Add 100 parts of α, ω-dihydroxy polydimethylsiloxane and 5 parts of vinyltriethoxysilane into the reaction kettle, and stir to raise the temperature to At about 60°C, add 0.1 part of the above-mentioned isopropylamine formate, keep it warm for about 3 hours, heat up to 110°C and distill under reduced pressure for 1 hour, remove low molecular weight, and obtain alkoxy-terminated polysiloxane polymer, product performance test results See Table 1 for details.

Embodiment 3

[0031] Catalyst preparation: 1 mol of aniline and 1 mol of formic acid were subjected to a salt-forming reaction in a flask at room temperature for 2 hours to prepare aniline formate.

[0032] Preparation of alkoxy-terminated polymer: Add 100 parts of α, ω-dihydroxypolydimethylsiloxane and 1 part of methyltriethoxysilane to the reaction kettle, and stir and heat up to At about 60°C, add 0.2 parts of the above-mentioned aniline formate, keep it warm for about 1h, then raise the temperature to 110°C and distill under reduced pressure for 1h to remove low molecular weight, and obtain an alkoxy-terminated polysiloxane polymer. The product performance test results are detailed See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com