Preparation method of alkoxy-terminated polydimethylsiloxane

A technology of hydroxyl polydimethylsiloxane and dimethylsiloxane is applied in the field of preparation of alkoxy-terminated polydimethylsiloxane, which can solve the problems affecting production efficiency, viscosity peak and poor storage stability. and other problems, to achieve the effect of high end capping efficiency, less addition and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

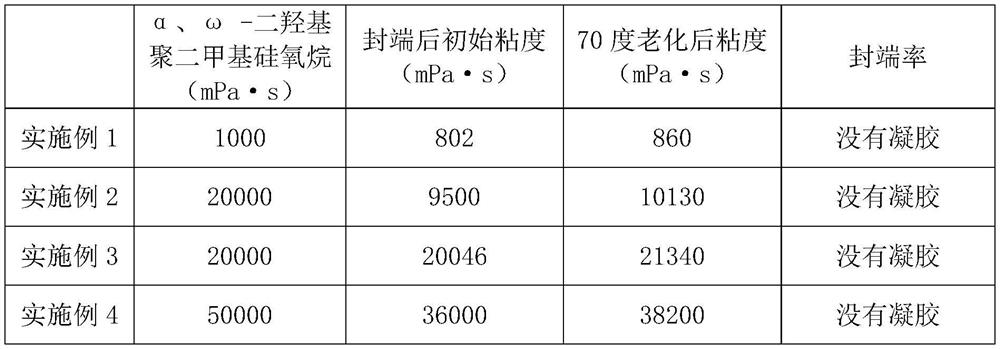

Embodiment 1

[0025] Prepare the alkoxy terminated polydimethylsiloxane as follows:

[0026] (1) Mix DMC and hexamethyldisiloxane and heat up to 170°C, add phosphoric acid dropwise, stir at 300r / min for 7 hours, reflux to remove water to obtain silicon phosphate terminator, DMC, hexamethyldisiloxane The mass ratio of oxane to phosphoric acid is 70:10:15.

[0027] (2) Warm up the linear body to 150°C, add potassium hydroxide aqueous solution with a mass concentration of 10%, and then stir the polycondensation reaction, monitor the viscosity online, and add the silicon phosphate terminator obtained in step (1) before reaching the target viscosity of 1000mPa·s, After continuing the reaction for 50 minutes, the low-boiling point substances were removed by vacuum vacuum distillation to obtain hydroxyl silicone oil. The mass ratio of linear body, potassium hydroxide aqueous solution, and silicon phosphate terminator was 40000:1:1.5.

[0028] (3) Add a certain proportion of methyltrimethoxysilane...

Embodiment 2

[0031] Prepare the alkoxy terminated polydimethylsiloxane as follows:

[0032] (1) Mix DMC and hexamethyldisiloxane and heat up to 170°C, add phosphoric acid dropwise, stir at 300r / min for 7 hours, reflux to remove water to obtain silicon phosphate terminator, DMC, hexamethyldisiloxane The mass ratio of oxane to phosphoric acid is 70:10:15.

[0033] (2) Warm up the linear body to 150°C, add potassium hydroxide aqueous solution with a mass concentration of 10%, and then stir the polycondensation reaction, monitor the viscosity online, and add the silicon phosphate terminator obtained in step (1) before reaching the target viscosity of 20000mPa·s, After continuing the reaction for 50 minutes, the low-boiling point substances were removed by vacuum vacuum distillation to obtain hydroxyl silicone oil. The mass ratio of linear body, potassium hydroxide aqueous solution, and silicon phosphate terminator was 40000:1:1.5.

[0034] (3) Add a certain proportion of methyltrimethoxysilan...

Embodiment 3

[0037] Prepare the alkoxy terminated polydimethylsiloxane as follows:

[0038] (1) Mix DMC and hexamethyldisiloxane and heat up to 170°C, add phosphoric acid dropwise, stir at 300r / min for 7 hours, reflux to remove water to obtain silicon phosphate terminator, DMC, hexamethyldisiloxane The mass ratio of oxane to phosphoric acid is 70:10:15.

[0039] (2) Warm up the linear body to 150°C, add potassium hydroxide aqueous solution with a mass concentration of 10%, and then stir the polycondensation reaction, monitor the viscosity online, and add the silicon phosphate terminator obtained in step (1) before reaching the target viscosity of 20000mPa·s, After continuing the reaction for 50 minutes, the low-boiling point substances were removed by vacuum vacuum distillation to obtain hydroxyl silicone oil. The mass ratio of linear body, potassium hydroxide aqueous solution, and silicon phosphate terminator was 40000:1:1.5.

[0040] (3) Add a certain proportion of methyltrimethoxysilan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com