A kind of preparation method of alkoxy-terminated polydimethylsiloxane

A technology of hydroxypolydimethylsiloxane and dimethylsiloxane, which is applied in the field of preparation of alkoxy-terminated polydimethylsiloxane, which can solve the problem of poor storage stability, affecting production efficiency, and peak viscosity and other problems, to achieve the effect of high stability, high end-capping efficiency, and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

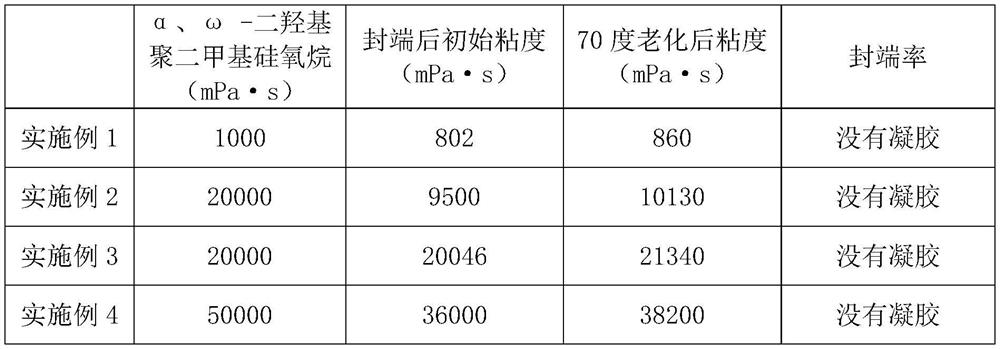

Embodiment 1

[0025] Follow the steps below to prepare alkoxy terminated polydimethylsiloxane:

[0026] (1) After mixing DMC and hexamethyldisiloxane, the temperature was raised to 170° C., phosphoric acid was added dropwise, stirred at a speed of 300 r / min for 7 hours, and water was removed by refluxing to obtain a silicon phosphate terminator, DMC, hexamethyldisiloxane The mass ratio of oxane and phosphoric acid is 70:10:15.

[0027] (2) heating the linear body to 150° C., adding a potassium hydroxide aqueous solution with a mass concentration of 10% and then stirring the polycondensation reaction, monitoring the viscosity on-line, and adding the silicon phosphate terminator obtained in step (1) before reaching the target viscosity of 1000 mPa·s, After the reaction was continued for 50 minutes, the low-boiling substances were removed by vacuum and reduced pressure distillation to obtain hydroxy silicone oil. The mass ratio of linear body, potassium hydroxide aqueous solution, and silicoph...

Embodiment 2

[0031] Follow the steps below to prepare alkoxy terminated polydimethylsiloxane:

[0032] (1) After mixing DMC and hexamethyldisiloxane, the temperature was raised to 170° C., phosphoric acid was added dropwise, stirred at a speed of 300 r / min for 7 hours, and water was removed by refluxing to obtain a silicon phosphate terminator, DMC, hexamethyldisiloxane The mass ratio of oxane and phosphoric acid is 70:10:15.

[0033] (2) heating the linear body to 150° C., adding a potassium hydroxide aqueous solution with a mass concentration of 10% and then stirring the polycondensation reaction, monitoring the viscosity on-line, and adding the silicophosphate terminator obtained in step (1) before reaching the target viscosity of 20000 mPa·s, After the reaction was continued for 50 minutes, the low-boiling substances were removed by vacuum and reduced pressure distillation to obtain hydroxy silicone oil. The mass ratio of linear body, potassium hydroxide aqueous solution, and silicopho...

Embodiment 3

[0037] Follow the steps below to prepare alkoxy terminated polydimethylsiloxane:

[0038] (1) After mixing DMC and hexamethyldisiloxane, the temperature was raised to 170° C., phosphoric acid was added dropwise, stirred at a speed of 300 r / min for 7 hours, and water was removed by refluxing to obtain a silicon phosphate terminator, DMC, hexamethyldisiloxane The mass ratio of oxane and phosphoric acid is 70:10:15.

[0039] (2) heating the linear body to 150° C., adding a potassium hydroxide aqueous solution with a mass concentration of 10% and then stirring the polycondensation reaction, monitoring the viscosity on-line, and adding the silicophosphate terminator obtained in step (1) before reaching the target viscosity of 20000 mPa·s, After the reaction was continued for 50 minutes, the low-boiling substances were removed by vacuum and reduced pressure distillation to obtain hydroxy silicone oil. The mass ratio of linear body, potassium hydroxide aqueous solution, and silicopho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com