Method for preparing alkyl end capping polyether using alkylsulfate as end capping reagent

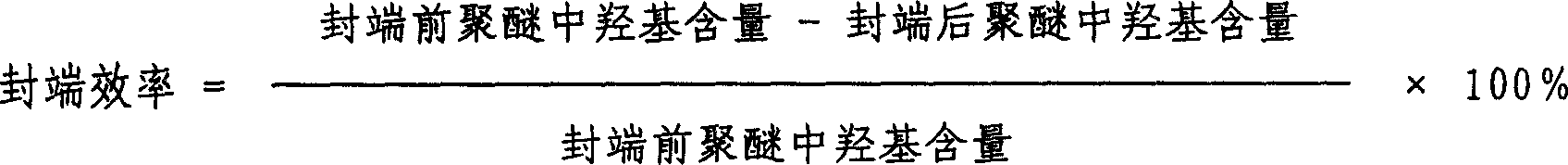

An alkyl sulfate and alkyl end-capping technology is applied in the field of preparing alkyl-terminated polyether by using alkyl sulfate as end-capping agent, which can solve problems such as increasing end-capping agent, avoid decomposition, reduce usage, The effect of improving the end-capping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

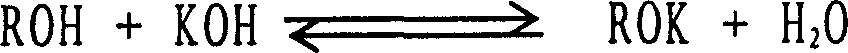

Method used

Image

Examples

Embodiment 1

[0033] Add 200 grams of butanol polyether (EO / PO=50 / 50, random, hydroxyester 36), 14.0 grams of solid potassium hydroxide, and 4.0 grams of anhydrous sodium sulfite (antioxidant) in a 500 ml four-necked flask, add 9.3 grams of calcium oxide, stirred vigorously. Under stirring, it was replaced with nitrogen four times, and reacted at 90-100° C. for 1 hour. Cool down to 40-45°C, add 15.8 grams of dimethyl sulfate dropwise, continue to react at 40-45°C for 2 hours, 60°C for 1 hour, and 90°C for 1 hour after the dropwise addition. Add 100 ml of water, stir at 90°C for 1 hour, maintain 80-90°C to allow the reactants to stand for stratification, remove the water phase, vacuum dehydrate, and filter to remove solid impurities to obtain the end-capped polyether product

Embodiment 2

[0035] Add 200 grams of polyethylene glycol (hydroxyl value 78), 30.4 grams of solid potassium hydroxide, 4.0 grams of anhydrous sodium sulfite, 20.3 grams of calcium oxide, and 80 milliliters of xylene in a 500 milliliter four-necked flask, blow nitrogen for 10 minutes, and then Stirring is carried out at a temperature of 90-100°C for 1 hour. Cool down to 40-45°C, add 30.2 grams of dimethyl sulfate dropwise, and continue to react at 40-45°C for 2 hours after the dropwise addition, 1 hour at 60°C, and 1 hour at 90°C. Add 100 ml of water, stir at 90°C for 1 hour, maintain 80-90°C to allow the reactants to stand for stratification, remove the water phase, remove the solvent in a vacuum, and filter to remove solid impurities to obtain a blocked polyether product.

Embodiment 3

[0037] Add 200 grams of glycerol polyether (EO / PO=30 / 70, random, hydroxyl value 37), 14.4 grams of solid potassium hydroxide, 4.0 grams of anhydrous sodium sulfite, and 9.6 grams of calcium oxide in a 500 milliliter four-necked flask, and stir The mixture was replaced with nitrogen four times, and then stirred and reacted at 90-100° C. for 1 hour. Cool down to 40-45°C, add 16.2 g of dimethyl sulfate dropwise, and then maintain 40-45°C to continue the reaction for 2 hours, 1 hour at 60°C, and 1 hour at 90°C. Add 100 ml of water, stir at 90°C for 1 hour, maintain 80-90°C to allow the reactants to stand for stratification, remove the water phase, vacuum dehydrate, and filter to remove solid impurities to obtain a blocked polyether product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com