Yellowing-resistant UV-curing liquid-state optical transparent adhesive and preparation method thereof

An optically transparent adhesive and anti-yellowing technology, which is applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of low end-blocking rate and yellowing of large monomers, and achieve short reaction time and fast reaction time. Fast speed and good storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

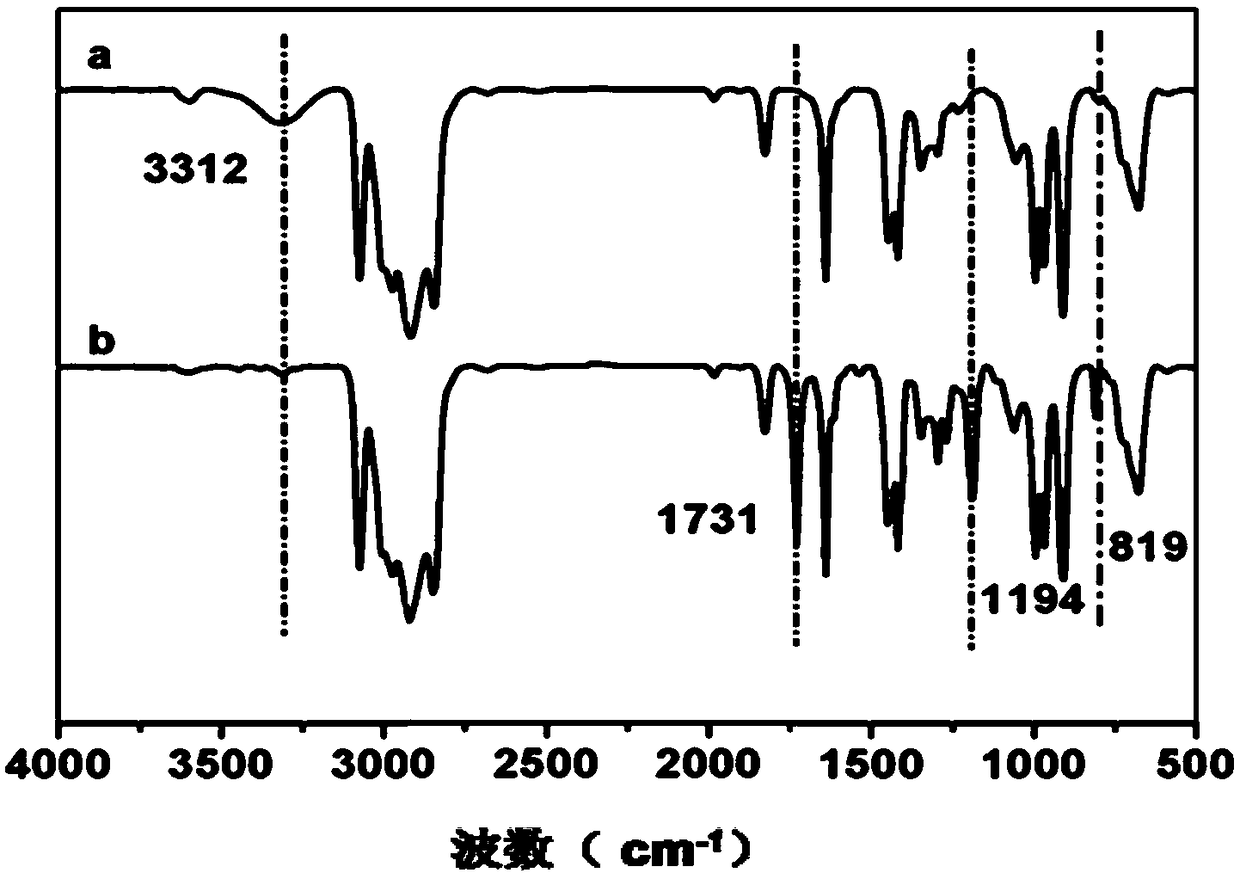

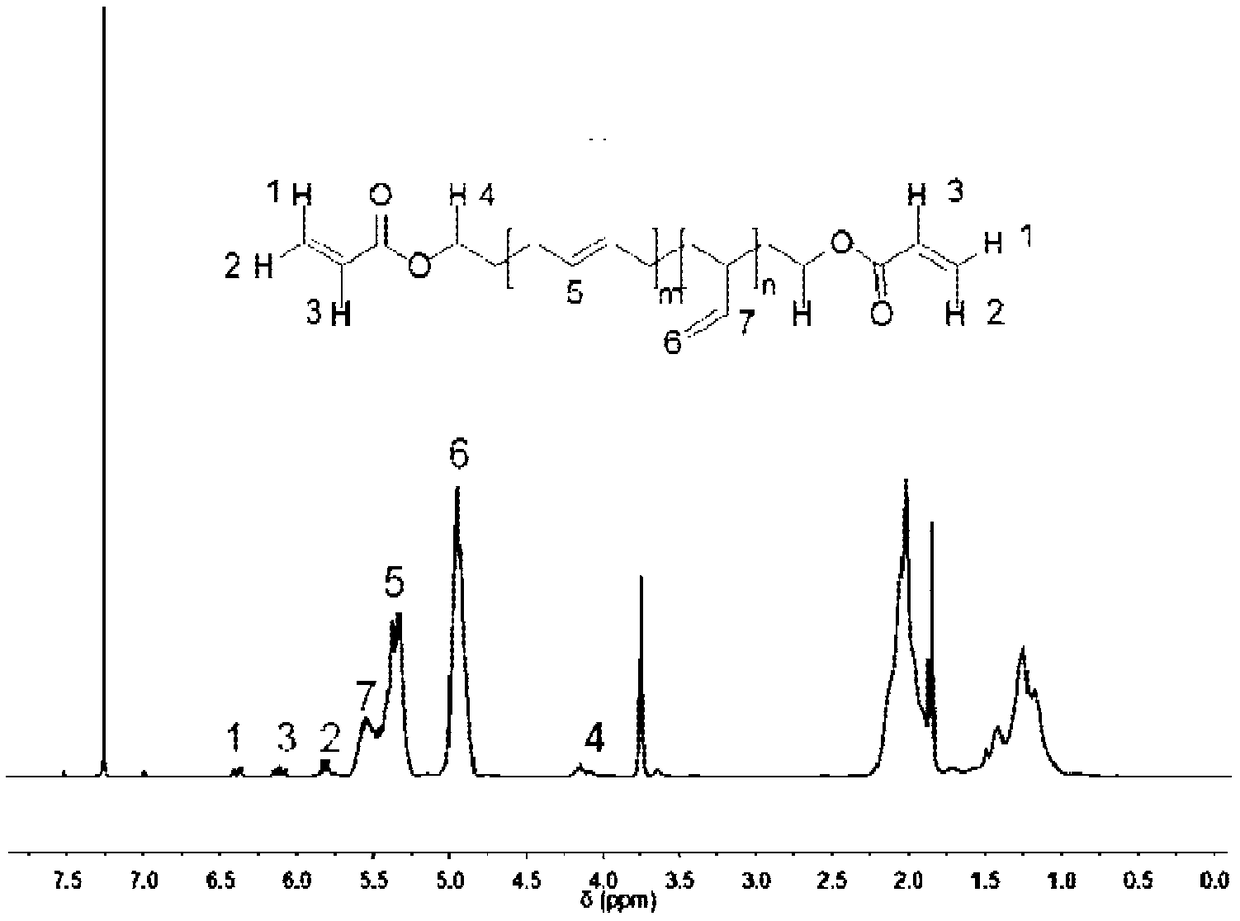

[0042] Embodiment 1, the synthesis of polybutadiene acrylate macromonomer

[0043] Add 10g of hydroxyl-terminated polybutadiene (hydroxyl content 0.64mmol / g) to a dry and clean 100ml three-neck flask, distill 60ml of THF, stir until clear and transparent under the protection of argon, add 0.66mmol of potassium naphthalene with a syringe and react at room temperature 1h, add 0.06g of acryloyl chloride (0.70mmol) to react for 0.5h, filter, precipitate with absolute ethanol and water for 3 times respectively, and vacuum dry at 50°C. The polybutadiene acrylate macromonomer is obtained with a yield of about 92%.

Embodiment 2

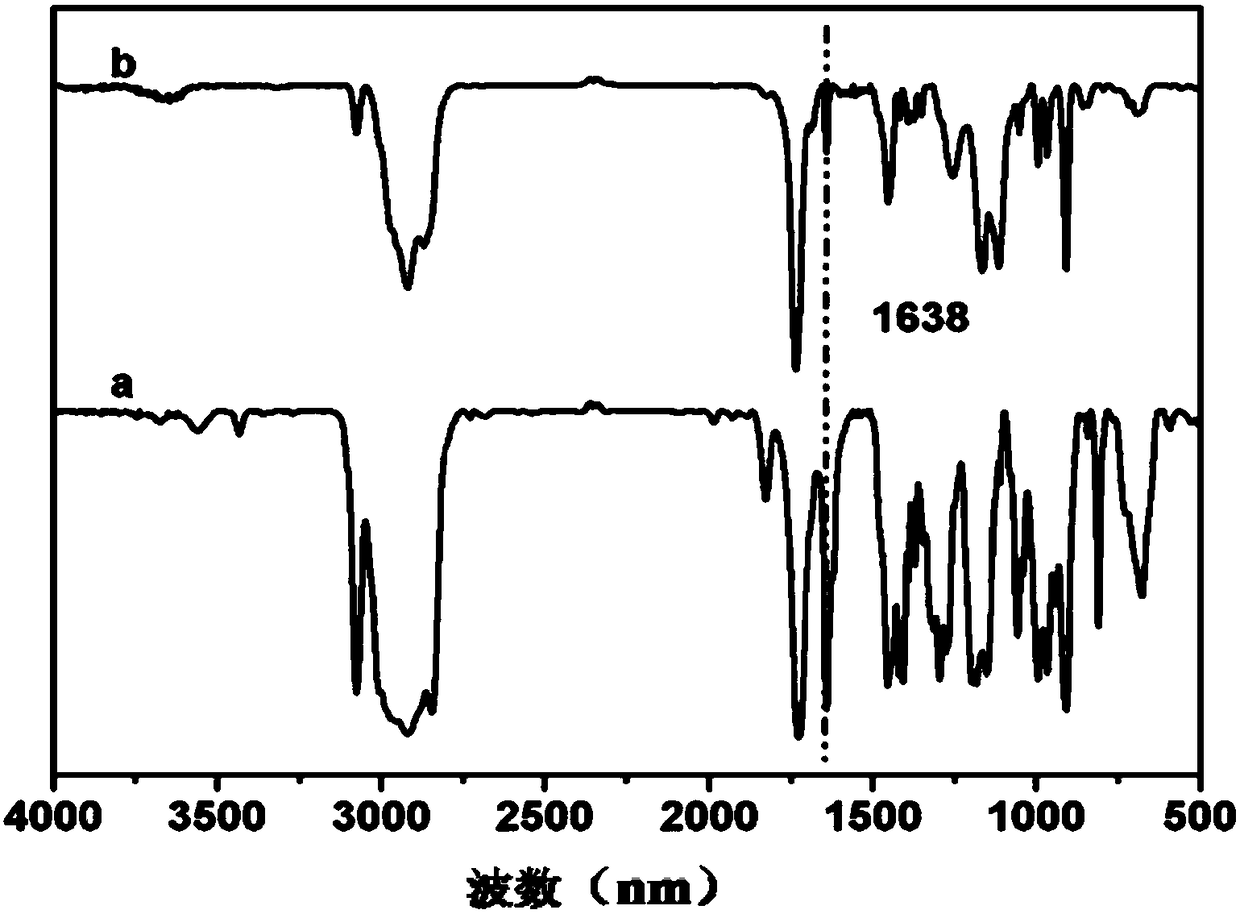

[0044] Embodiment 2, anti-yellowing UV curing liquid optically transparent adhesive preparation method

[0045] In the 100ml there-necked flask equipped with a stirrer, add 2.3g of polybutadiene acrylate macromonomer prepared in Example 1, 0.46g of isobornyl acrylate, 1.61g of ethoxyethoxyethyl acrylate, 0.23g of 1,6-hexanediol diacrylate, 0.46g of polybutadiene resin, after stirring evenly, add 0.23g of photoinitiator 2-hydroxy-2-methyl-1-phenylacetone (1173), continue Stir for 2 hours until uniform and transparent to obtain a UV-curable liquid optically transparent adhesive that is resistant to yellowing.

Embodiment 3

[0047] In the 100ml there-necked flask equipped with a stirrer, add 2.75g of polybutadiene acrylate macromonomer prepared in Example 1, 0.46g of isobornyl acrylate, 1.14g of ethoxyethoxyethyl acrylate, 1,6-hexanediol diacrylate 0.23g, polybutadiene resin 0.46g after stirring evenly, add photoinitiator 2-hydroxyl-2-methyl-1-phenylacetone (1173) 0.23g, polybutadiene Diene resin 0.46g, continue to stir for 2h until it is uniform and transparent, and a UV curable liquid optically transparent adhesive that is resistant to yellowing is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com