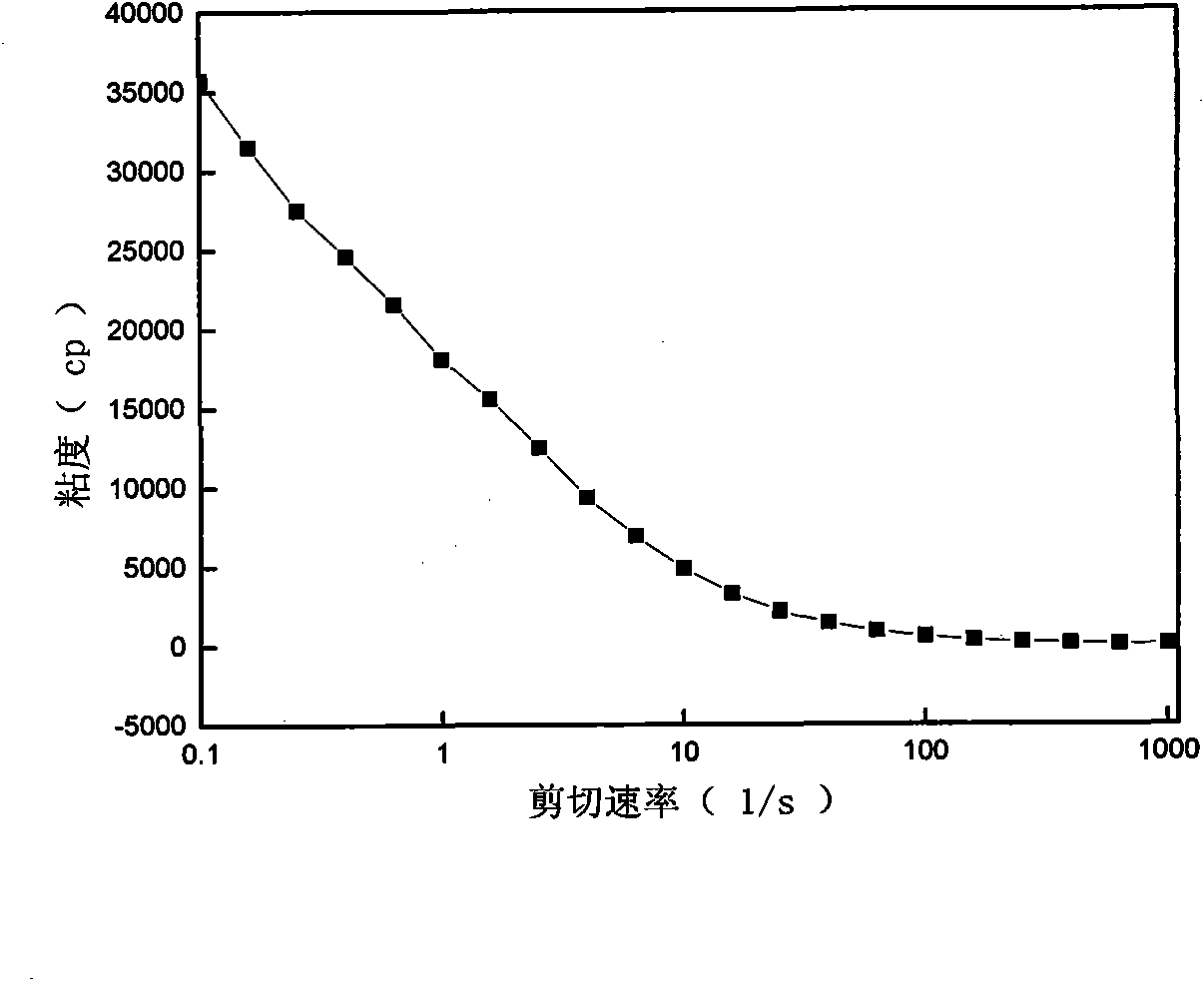

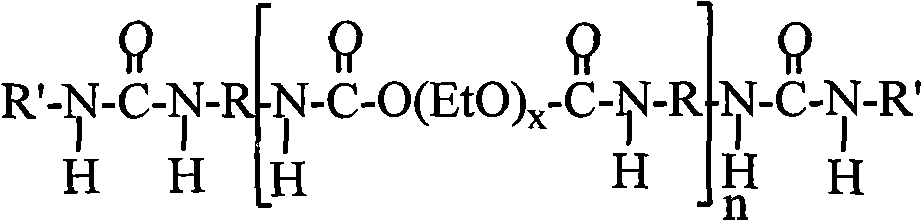

Poly(urethane-urea) associative thickener and preparation method and application thereof

A technology of associative thickener and urethane, applied in coatings, latex paints, etc., can solve the problems of coating stability, poor leveling, etc., achieve improved end-capping rate, stable storage performance, and shortened reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 80 parts (mass ratio) of PEG6000 and 250 parts of toluene into a four-necked flask equipped with a stirrer, thermometer and distillation device, raise the temperature to 120°C to distill 100 parts of toluene, cool down to 50°C, add 4.68 parts of IPDI, Then add 0.3 parts of dibutyltin dilaurate (mass ratio). Under rapid stirring, the temperature was raised to 70° C. for 2 hours. Then, 10 parts of hexadecylamine and 0.1 part of triethylenediamine (mass ratio) were added to the prepolymer solution, and the temperature was raised to 80° C. for 6 hours to obtain a yellow transparent liquid. The product was poured into 3 times the volume of petroleum ether, and the resulting precipitate was filtered and vacuum-dried to obtain poly(urethane-urea).

[0051] Get 20 parts of dry poly(urethane-urea), 20 parts of ethylene glycol butyl ethers, 60 parts of deionized water mix and dissolve, be mixed with the solution that mass concentration is 20%, as thickening styrene-acrylic e...

Embodiment 2

[0057] Add 80 parts (mass ratio) of PEG6000 and 250 parts (mass ratio) of toluene into a four-neck flask equipped with a stirrer, a thermometer and a distillation device, raise the temperature to 120°C to distill 80 parts (mass ratio) of toluene, and cool down to 50 ℃, add 3.9 parts of IPDI, 0.5 parts of dibutyltin dilaurate (mass ratio). Under rapid stirring, the temperature was raised to 80°C for 6 hours, and then added. Then add 10 parts (mass ratio) of hexadecylamine and 0.4 parts of triethylenediamine (mass ratio) to the prepolymer solution, and react for 8 hours to obtain a yellow transparent liquid. The product was poured into 3 times the volume of petroleum ether, and the resulting precipitate was filtered and vacuum-dried.

[0058] Get 20 parts of dry thickening agent, 20 parts of ethylene glycol butyl ether, 60 parts of deionized water mix and dissolve, be configured into the solution that mass concentration is 20%, as thickening styrene-acrylic emulsion (styrene-ac...

Embodiment 3

[0063] Add 80 parts (mass ratio) of PEG10000 and 250 parts (mass ratio) of toluene into a four-necked flask equipped with a stirrer, a thermometer and a distillation device, raise the temperature to 135°C to distill 90 parts (mass ratio) of toluene, and cool down to 50 °C, add 3.56 parts of IPDI, add 0.1 part of dibutyltin dilaurate (mass ratio), and heat up to 60 °C for 2 hours under rapid stirring. Then, 10 parts (mass ratio) of hexadecylamine and 0.4 parts of triethylenediamine (mass ratio) were added to the prepolymer solution, and the temperature was raised to 80° C. for 2 hours. A yellow transparent liquid was obtained, and the product was poured into 3 times the volume of petroleum ether, and the resulting precipitate was filtered and vacuum-dried.

[0064] Get 20 parts of dry thickening agent, 20 parts of ethylene glycol butyl ether, 60 parts of deionized water mix and dissolve, be configured into the solution that mass concentration is 20%, as thickening styrene-acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com