High efficient washing agent composition for washing textiles

A detergent and textile technology, applied in the field of daily chemicals, can solve the problems of inability to completely wash off stains, easily damaged clothes, poor washing effect, etc., and achieve the effect of protecting the color of clothes, strong detergency, and fresh smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

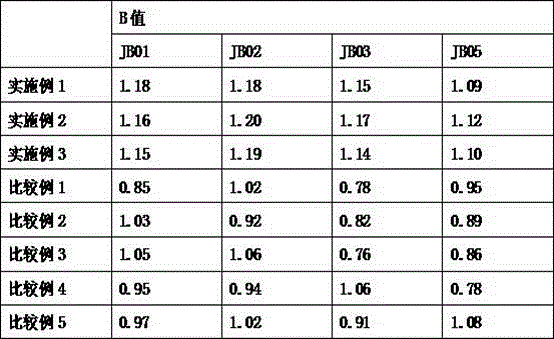

Examples

Embodiment 1

[0023] A high-efficiency detergent composition for cleaning textiles, made of the following raw materials in parts by weight: 5 parts of fatty acid diethanolamide, 10 parts of dodecyl dimethyl benzyl ammonium chloride, dodecyl dimethyl 8 parts of betaine, 6 parts of chitosan, 4 parts of sodium fatty acid methyl ester sulfonate, 1 part of sodium alginate, 2 parts of sodium sulfate, 2 parts of sodium perborate, 3 parts of sodium citrate, 2 parts of triethanolamine, hydroxyl 3 parts of propyl methylcellulose sodium, 4 parts of polyvinylpyrrolidone, 3 parts of oxidized corn starch, 0.8 parts of tea saponin, 1.2 parts of fungicide, 1 part of chelating agent, 0.2 parts of essence, 6 parts of glycerin, 8 parts of ethanol, 40 parts of deionized water;

[0024] The preparation method comprises the following steps:

[0025] (1) Prepare materials according to the dosage of each component;

[0026] (2) Add deionized water to the configuration tank, and heat it, the temperature is contro...

Embodiment 2

[0031] A high-efficiency detergent composition for cleaning textiles, made of the following raw materials in parts by weight: 8 parts of fatty acid diethanolamide, 7 parts of dodecyl dimethyl benzyl ammonium chloride, dodecyl dimethyl 8 parts of betaine, 5 parts of chitosan, 2 parts of sodium fatty acid methyl ester sulfonate, 1.5 parts of sodium alginate, 2.5 parts of sodium sulfate, 1.5 parts of sodium perborate, 2.5 parts of sodium citrate, 1.5 parts of triethanolamine, hydroxyl 4 parts of propyl methylcellulose sodium, 3 parts of polyvinylpyrrolidone, 2 parts of oxidized corn starch, 0.6 parts of tea saponin, 1.8 parts of fungicide, 1.5 parts of chelating agent, 0.4 parts of essence, 10 parts of glycerin, 5 parts of ethanol, 35 parts of deionized water;

[0032] The preparation method comprises the following steps:

[0033] (1) Prepare materials according to the dosage of each component;

[0034] (2) Add deionized water to the configuration tank, and heat it, the tempera...

Embodiment 3

[0039] A high-efficiency detergent composition for cleaning textiles, made of the following raw materials in parts by weight: 10 parts of fatty acid diethanolamide, 6 parts of dodecyl dimethyl benzyl ammonium chloride, dodecyl dimethyl 10 parts of betaine, 9 parts of chitosan, 5 parts of sodium fatty acid methyl ester sulfonate, 2 parts of sodium alginate, 3 parts of sodium sulfate, 2.5 parts of sodium perborate, 3 parts of sodium citrate, 2.5 parts of triethanolamine, hydroxyl 2 parts of propyl methylcellulose sodium, 5 parts of polyvinylpyrrolidone, 3.5 parts of oxidized corn starch, 0.4 parts of tea saponin, 0.6 parts of fungicide, 1.8 parts of chelating agent, 0.3 parts of essence, 5 parts of glycerin, 10 parts of ethanol, 40 parts of deionized water;

[0040] The preparation method comprises the following steps:

[0041] (1) Prepare materials according to the dosage of each component;

[0042](2) Add deionized water to the configuration tank, and heat it, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com