Reticular nano hole zinc oxide micron hollow ball and preparation method thereof

A zinc oxide micron and hollow sphere technology, applied in nanostructure manufacturing, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problem that zinc oxide micron hollow spheres cannot be produced, the shape and size of the hollow part are difficult to control, and the environment causes Pollution and other problems, to achieve the effect of easy control of various parameters, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

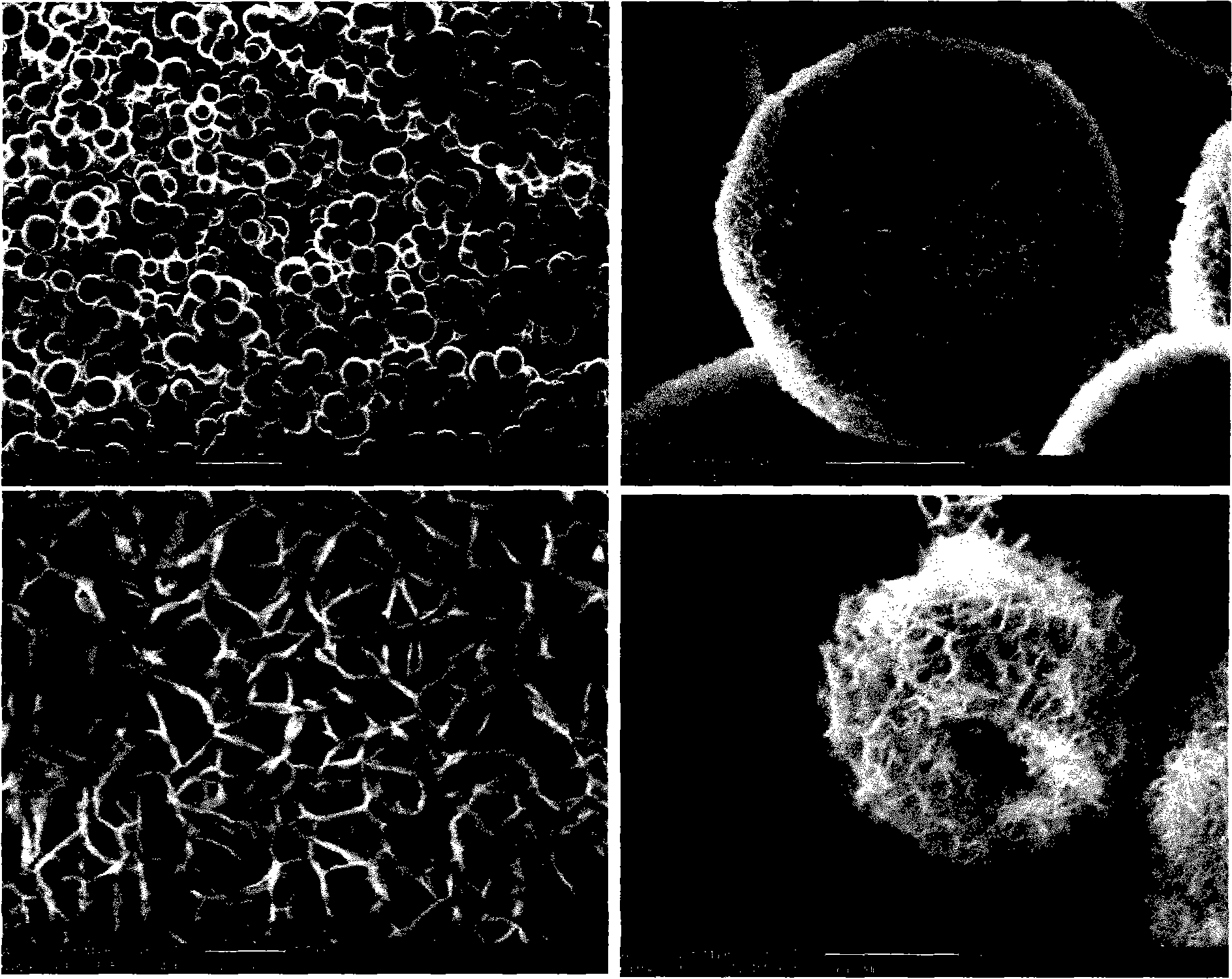

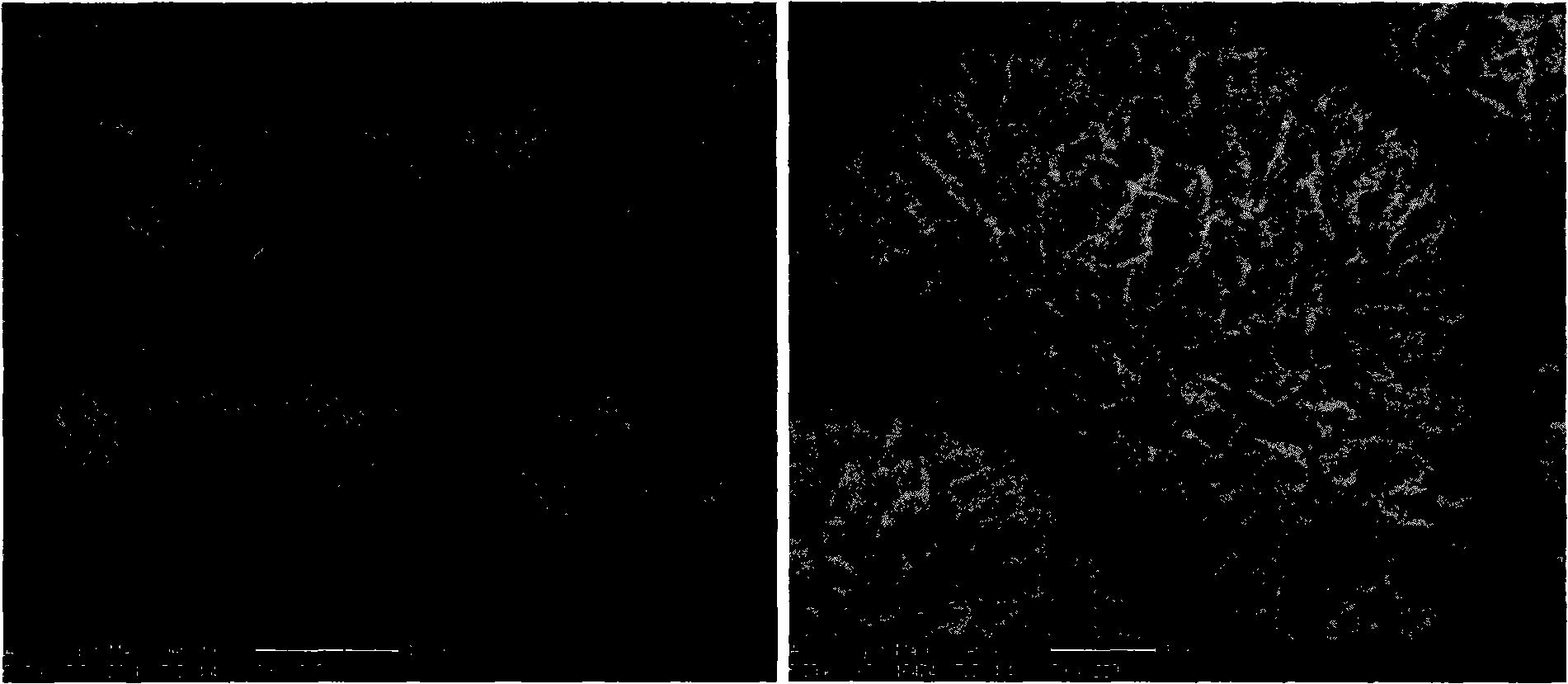

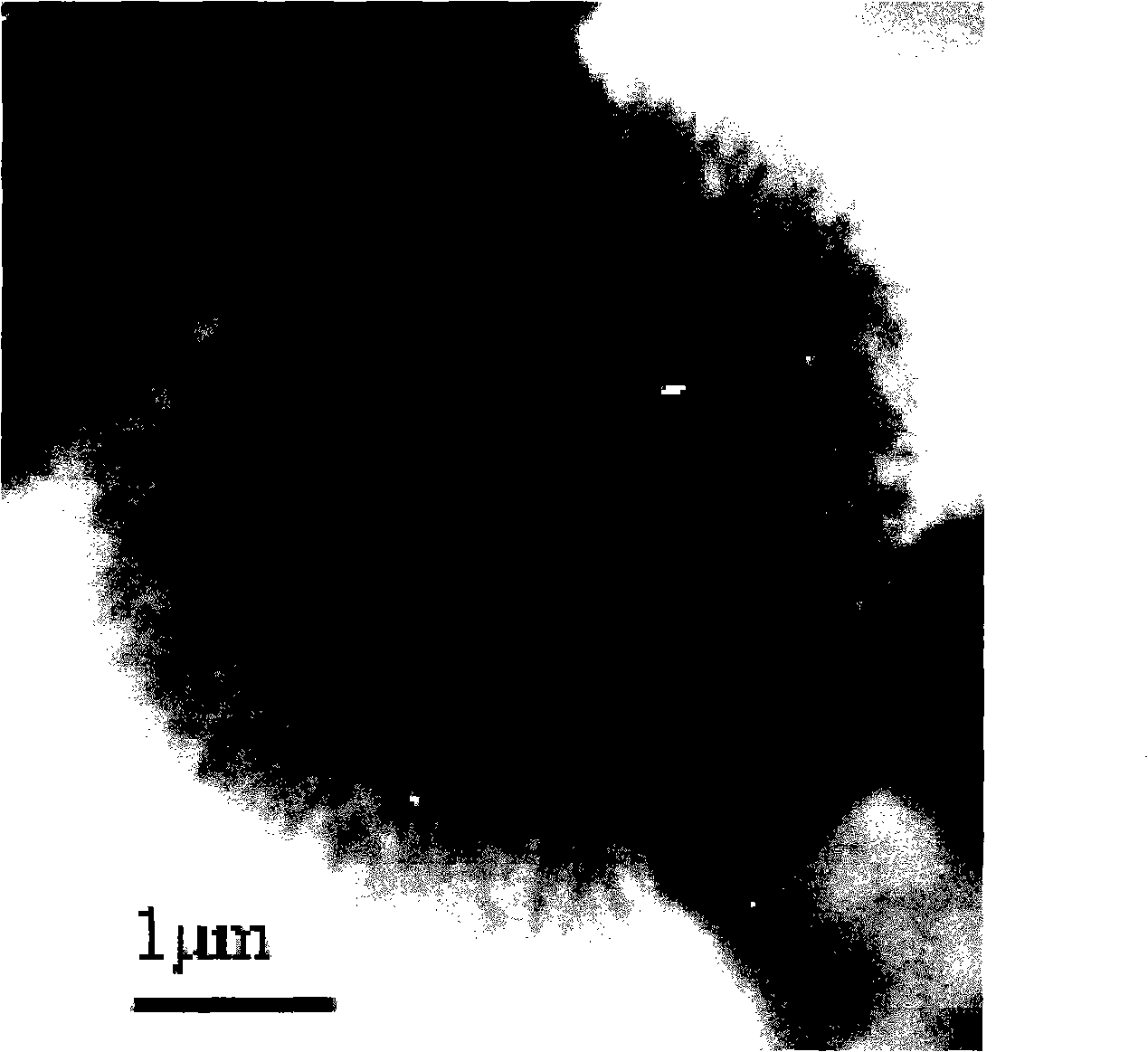

[0018] Embodiment 1: complete preparation successively according to the following steps: a) according to the molar ratio of zinc salt: chelating agent: sodium citrate: water=1: 0.5: 0.15: 50, be placed in container after weighing and stir to dissolve, after sealing The product is obtained by incubating at 70° C. for 10 hours under the state; wherein zinc nitrate is selected as the zinc salt, urea is selected as the chelating agent, and deionized water is selected as the water. The product was obtained as a white precipitate. b) filter the white precipitate first, and wash it with water once to obtain the following figure 1 and image 3 as shown and as Figure 4 The network nanoporous micron hollow sphere shown in the curve in (a) is then heated at 300°C for 3 hours to obtain the following figure 2 as shown and as Figure 4 Figure (b) of and Figure 5 The networked nanoporous ZnO micron hollow spheres shown in the middle curve.

Embodiment 2

[0019] Embodiment 2: complete preparation successively according to the following steps: a) according to the molar ratio of zinc salt: chelating agent: sodium citrate: water=1: 0.8: 0.13: 75, be placed in container and stir to dissolve after weighing, after sealing The product is obtained by incubating at 77° C. for 9 hours under the state; wherein zinc nitrate is selected as the zinc salt, urea is selected as the chelating agent, and deionized water is selected as the water. The product was obtained as a white precipitate. b) first filter the white precipitate, and wash it with water for 2 times to obtain the following figure 1 and image 3 as shown and as Figure 4 (a) network nanoporous micron hollow spheres shown in the curve, and then heated at 350 ° C for 2.5 hours to obtain the following figure 2 as shown and as Figure 4 Figure (b) of and Figure 5 The networked nanoporous ZnO micron hollow spheres shown in the middle curve.

Embodiment 3

[0020] Embodiment 3: complete preparation successively according to the following steps: a) according to the molar ratio of zinc salt: chelating agent: sodium citrate: water=1: 1: 0.1: 100, be placed in container after weighing and stir to dissolve, after sealing The product is obtained by incubating at 85° C. for 7 hours under the state; wherein zinc nitrate is selected as the zinc salt, urea is selected as the chelating agent, and deionized water is selected as the water. The product was obtained as a white precipitate. b) first filter the white precipitate and wash it with water for 3 times to obtain the following: figure 1 and image 3 as shown and as Figure 4 The network nanoporous micron hollow sphere shown in the curve in (a) is then heated at 400°C for 2 hours to obtain the following figure 2 as shown and as Figure 4 Figure (b) of and Figure 5 The networked nanoporous ZnO micron hollow spheres shown in the middle curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com