Coating composite and optical fiber containing same

A composition and coating technology, applied in the directions of clad optical fibers, coatings, optical waveguides and light guides, etc., can solve the problems of slow coating speed, etc., and achieve the effects of fast curing speed, bright color and flexible texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Raw materials: get hydroxyethyl acrylate, ζ-caprolactone and phthalic anhydride, poly(ζ-caprolactone) and epoxy resin (manufacturer Changchun Chemical (Jiangsu Co., Ltd.) company), the mass ratio of brand BE-188EL) is 6:1.

[0038] The preparation method is as follows:

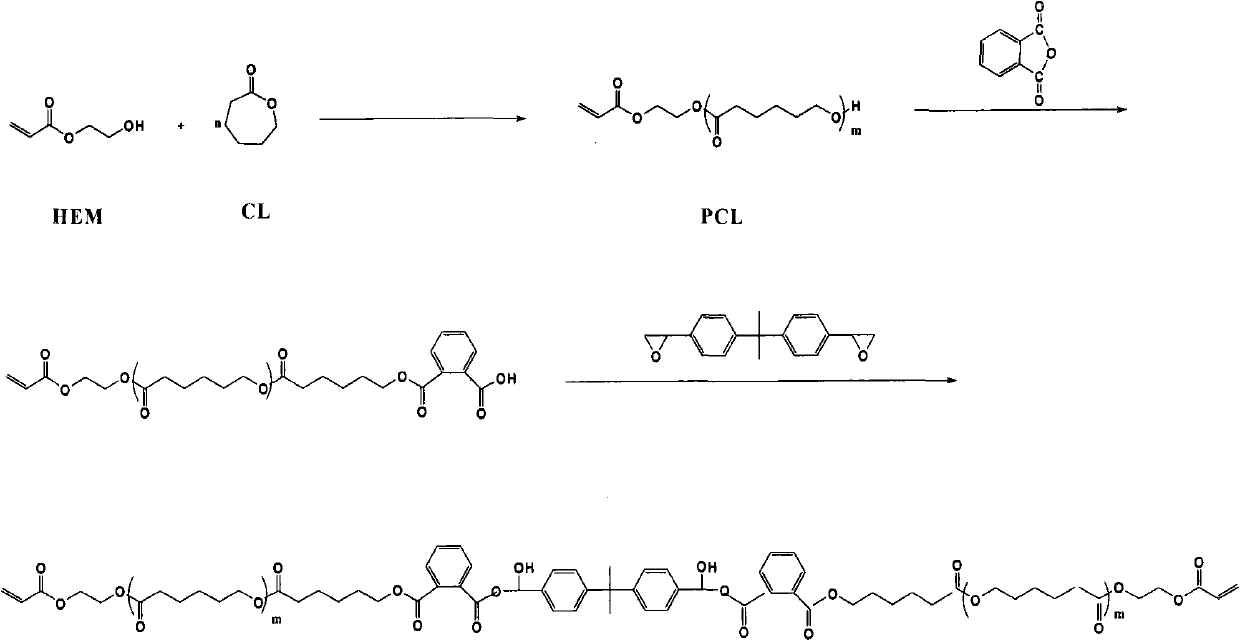

[0039] (1) Make hydroxyethyl acrylate and ζ-caprolactone under the catalysis of stannous octoate and in an inert atmosphere, adjust the temperature to 80°C, react for 3 hours, then precipitate poly(ζ-caprolactone) with petroleum ether (PCL).

[0040] (2) Make poly(ζ-caprolactone) and phthalic anhydride react in toluene solvent under the catalysis of triethylamine, the temperature is maintained between 80-100 ℃, after reacting for 2 hours, to the reaction system Add standard bisphenol A epoxy resin to it, and react until the acid value is less than 2mg / KOH.

[0041] (3) After removing most of the solvent, precipitate the product with petroleum ether to obtain poly(ζ-caprolactone)-modified epoxy acryli...

Embodiment 2

[0043] Raw materials: hydroxyethyl acrylate, ζ-caprolactone and phthalic anhydride are used in a mass ratio of 1:10:1.27, and the mass ratio of poly(ζ-caprolactone) and epoxy resin is 11:1.

[0044] The preparation method is as follows:

[0045] (1) Make hydroxyethyl acrylate and ζ-caprolactone under the catalysis of stannous octoate and in an inert atmosphere, adjust the temperature to 85 ° C, react for 6 hours, then precipitate poly(ζ-caprolactone) with petroleum ether (PCL).

[0046] (2) Make poly(ζ-caprolactone) and phthalic anhydride react in toluene solvent under the catalysis of triethylamine, the temperature is maintained between 80-100 ℃, after two hours of reaction, to the reaction system Add standard bisphenol A epoxy resin to it, and react until the acid value is less than 2mg / KOH.

[0047] (3) After removing most of the solvent, precipitate the product with petroleum ether to obtain poly(ζ-caprolactone)-modified epoxy acrylic resin (PCLER).

[0048] The ingredi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com