Tobacco stem modified processing method for paper-making process reconstituted tobaccos

A technology for reconstituting tobacco leaves and a treatment method, which is applied in the field of modification treatment of tobacco stem components, and can solve the problems of lack of tobacco stem components and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

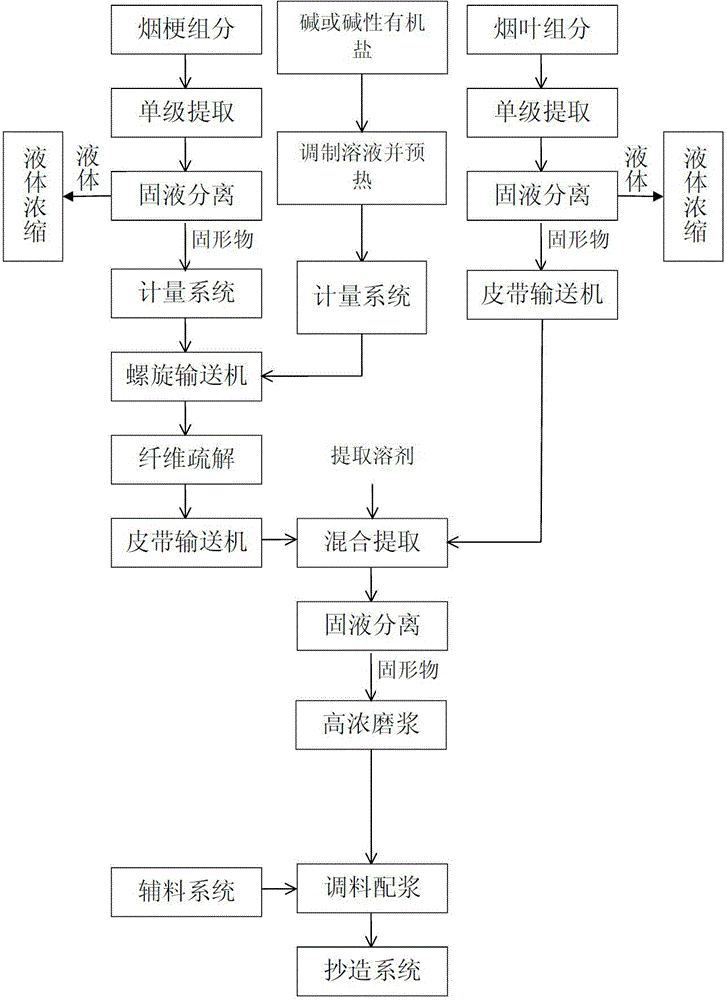

[0011] Embodiment one: choose the CG-1 product of a certain papermaking method tobacco sheet production plant. refer to figure 1 The production process is produced according to the following steps:

[0012] a. The tobacco stem component and the tobacco leaf component are respectively added to the extract to carry out a single extraction (single-stage extraction), and the solid-liquid separation is carried out through the solid-liquid separation equipment;

[0013] b. concentrating the extract of the tobacco leaf component as a leaf paste, and concentrating the extract of the tobacco stem component as a stem paste;

[0014] c. The solid matter of the separated tobacco stem component is sent to conveying equipment such as a screw conveyor, and the NaOH of 0.3% absolute dry weight of the tobacco stem solid is weighed, and the NaOH is adjusted to an aqueous solution with a mass concentration of 11% and preheated to After 30°C-35°C, add it to the conveying equipment and mix it wi...

Embodiment 2

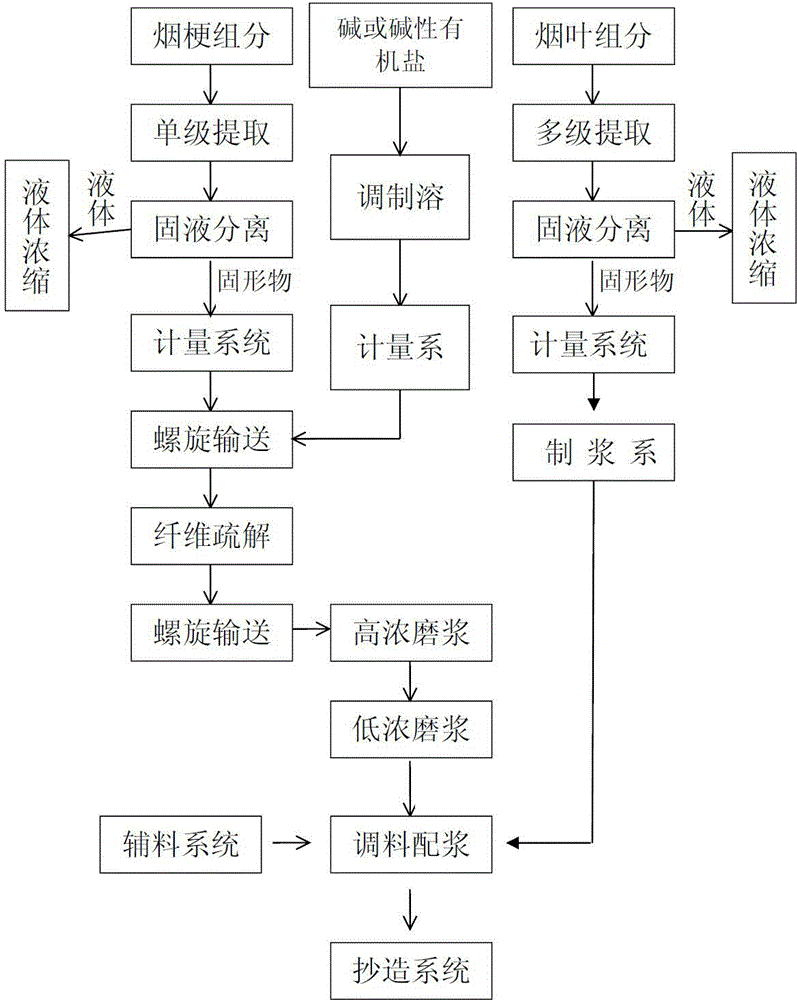

[0019] Embodiment two: choose the GD-01 product of a certain papermaking method tobacco sheet production plant. refer to figure 2 The production process is produced according to the following steps:

[0020] a. adding the tobacco stem components to the extracting solution for single-stage extraction and solid-liquid separation; and for the tobacco leaf components through multi-stage extraction for solid-liquid separation;

[0021] b. concentrating the extract of the tobacco leaf component as a leaf paste, and concentrating the extract of the tobacco stem component as a stem paste;

[0022] c. The solid matter of the separated tobacco stem component is sent to a conveying device such as a screw conveyor, and KOH with an absolute dry weight of 3% of the tobacco stem solid matter is weighed, and the KOH is adjusted to an aqueous solution with a mass concentration of 10% to 12% and After preheating to 60°C-65°C, add it to the conveying equipment and mix it with the solid conten...

Embodiment 3

[0028] Embodiment three: choose the TS-Y product of a paper-making method tobacco sheet production plant, other method steps are the same as embodiment two, just use sodium citrate to modify the tobacco stem solids after extraction treatment, and the tobacco stem solids 5% sodium citrate by absolute dry weight is adjusted to a solution with a mass ratio concentration of 10%, preheated to 40°C-50°C, and added to the solid. Produce products according to the requirements of TS-Y product manufacturing process.

[0029] The measured physical and chemical indicators of the product meet the requirements of YC / T16.3-2003, and also meet the user's requirements for physical and chemical indicators of TS-Y products. The chloride ion content of the product produced by the invention is 10.71% lower than that of the original product. The reduction of chloride ion content is beneficial to improve the flammability of the product.

[0030] Take the above product and the TS-Y product produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com