High-temperature-resistant silicone rubber foam material and preparation method thereof

A foam material and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant silicone rubber foam material and its preparation, can solve the problems of poor tensile strength of silicone rubber foam material, high amount of pore-forming agent, complicated intermediate process, etc., and achieve excellent The effect of comprehensive performance, low weight loss and longitudinal deformation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

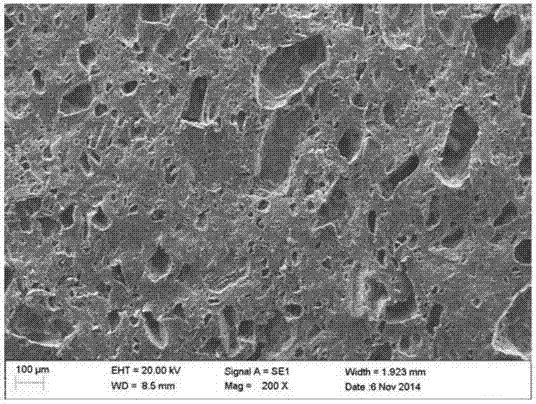

Image

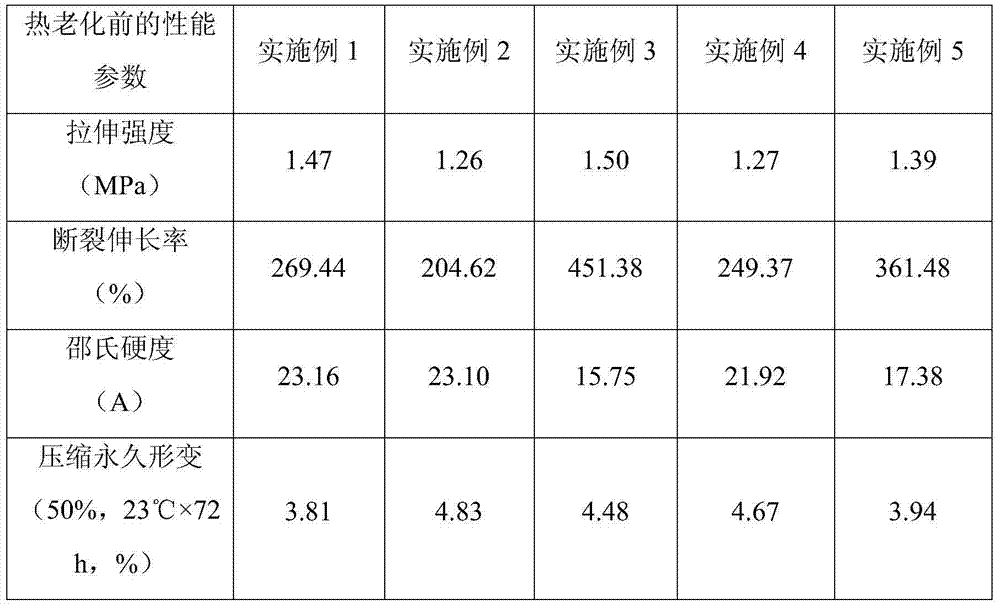

Examples

Embodiment 1

[0040] Step 1. Take 20g of methyl vinyl silicone rubber and add it to the double-roller open mill, masticate at room temperature for 5 minutes, then add 5g of fumed silica, 0.5mL of hydroxyl silicone oil, mix for 5 minutes, and then add 30g of urea , Triallyl cyanurate 1g, continue mixing for 10 minutes to obtain a rubber compound, then store the rubber compound statically at room temperature for 48 hours, then return the rubber compound for 10 minutes at room temperature, and then The rubber material that has been re-milled is molded into a sheet or a block on a tablet press; the rotating drum speed of the two-roll mill is set to 200r.min -1 ; The die used in the molding is stainless steel;

[0041] Step 2. After the formed sheet or block is plastic-sealed, place it in the air at room temperature 60 The absorbed dose rate in the Coγ single-plate radiation field is 130Gy.min -1 Carry out radiation cross-linking at the position where the absorbed dose is 50kGy, so that the ru...

Embodiment 2

[0044] Step 1. Take 50g of methyl vinyl silicone rubber and add it to the double-roller open mill, masticate for 5 minutes at room temperature, then add 15g of precipitated silica, 1mL of hydroxyl silicone oil, and 0.1g of phthalocyanine green, and mix for 5 minutes , then add 35g of urea and 2g of triallyl cyanurate, continue mixing for 10 minutes to obtain a rubber compound, then store the rubber compound at room temperature for 48 hours, and then re-mill the rubber compound at room temperature In 10 minutes, at room temperature, the sizing material that has been re-milled is molded into a sheet or block on a tablet press; the rotating drum speed of the two-roll mill is set to 300r.min -1 ; The mold used in the molding is polyethylene;

[0045] Step 2. After the formed sheet or block is plastic-sealed, place it in the air at room temperature 60 Absorbed dose rate in Coγ single plate radiation field is 160Gy.min -1 Carry out radiation cross-linking at the position where the...

Embodiment 3

[0048] Step 1. Take 100g of methyl vinyl silicone rubber and add it to a two-roller open mill, masticate for 5 minutes at room temperature, then add 20g of fumed silica and 3mL of hydroxyl silicone oil, mix for 10 minutes, then add 120g of urea, Triallyl cyanurate 4.5g, continue to knead for 10 minutes, obtain sizing material, then said sizing material is statically stored at room temperature for 72 hours, then at room temperature the sizing material is returned to kneading for 15 minutes, at room temperature Next, mold the rubber material that has been re-milled into a sheet or block on a tablet press; the rotating drum speed of the two-roll mill is set to 400r.min -1 ; The mold used in the molding is polyethylene;

[0049] Step 2. After the formed sheet or block is plastic-sealed, place it in the air at room temperature 60 Absorbed dose rate in Coγ single-plate radiation field is 151Gy.min -1 Carry out radiation cross-linking at the position where the absorbed dose is 30kG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com