Instant automatic noodle making machine

An automatic flour-making technology, applied in dough forming machinery or equipment, dough sheeter/rolling machine/rolling pin, food preparation, etc., to achieve the effect of chewy texture, no cleaning, and automatic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

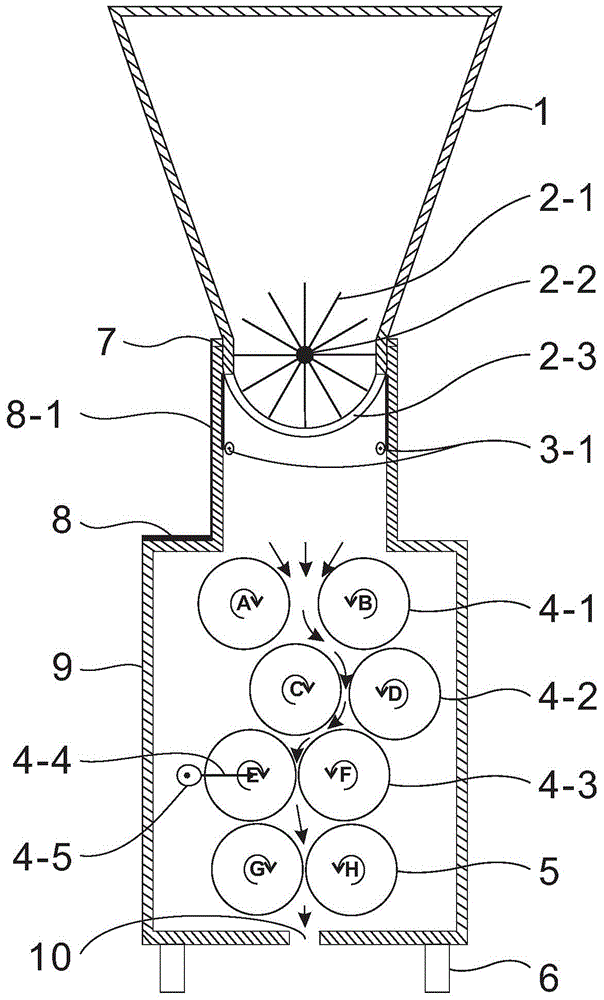

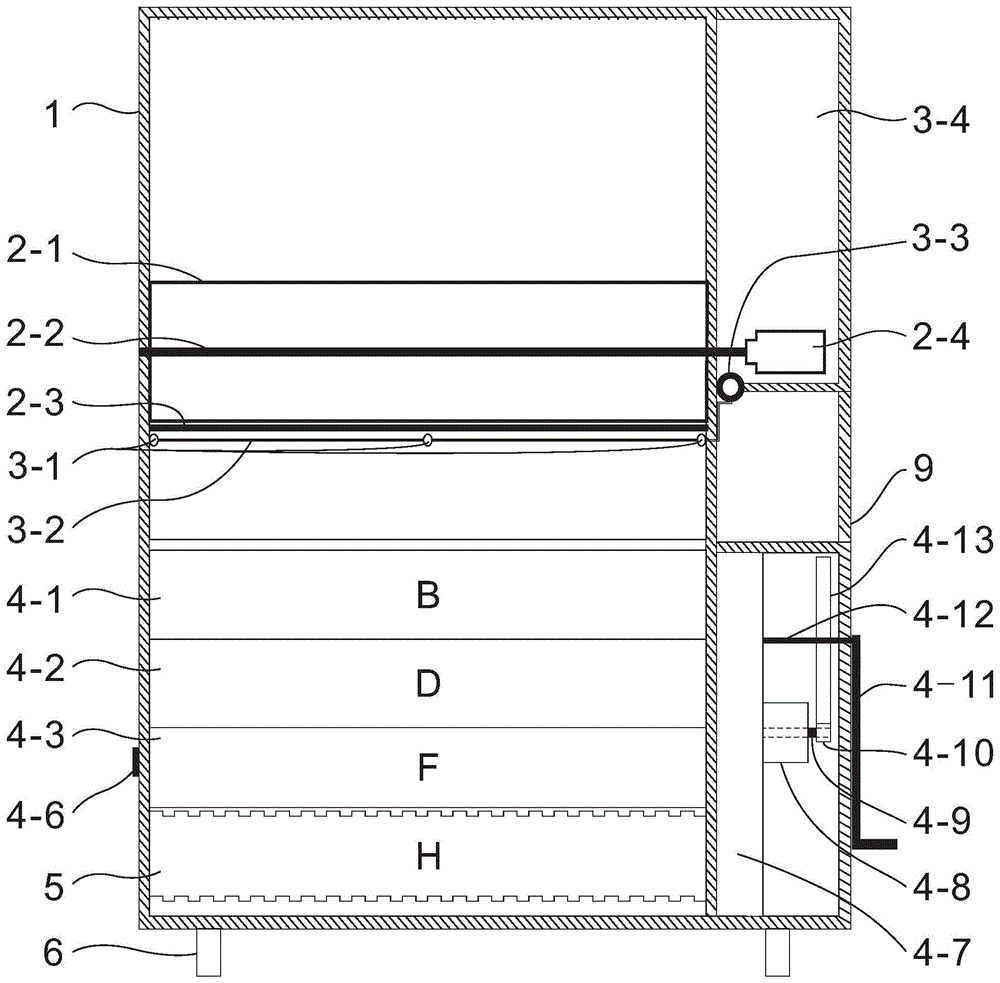

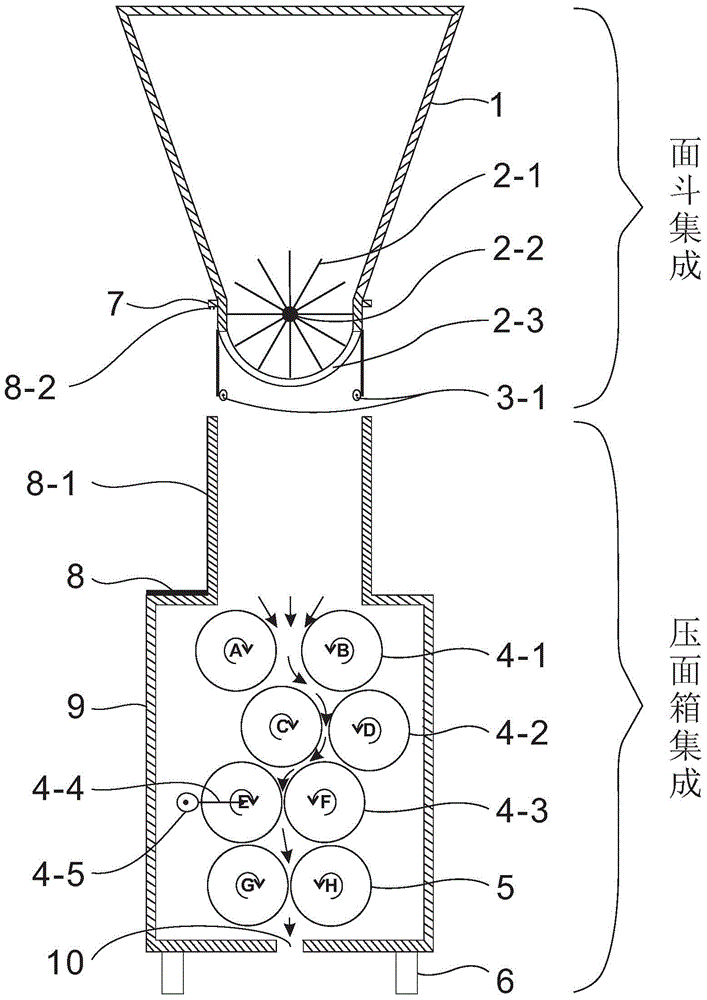

[0026] Embodiment one: Figure 1 to Figure 8 shown.

[0027] Flour micronization device: 1 is a flour bucket, 2-1 is a powder scraping sheet group, 2-2 is a powder scraping sheet shaft, 2-3 is a screen, 2-4 is a powder scraping motor, and 7 is a flour bucket support.

[0028] Water atomization device: 3-1 is an atomized water nozzle, 3-2 is a water pipe, 3-3 is an atomizer, and 3-4 is a water tank.

[0029] Noodle and dough pressing device and noodle cutting device: 4-1, 4-2, 4-3 are noodle pressing roller groups, each group contains two noodle rollers, 4-4 is distance adjusting rod, 4-5 is Adjustable distance cam, 4-6 is the adjustable distance handle, 4-7 is the pressing roller gear box, 4-8 is the pressing roller motor, 5 is the cutter, 6 is the machine foot, 9 is the pressing box, 10 is Come out.

[0030] The noodle and dough pressing device and the noodle cutting device are also connected with a hand-operated noodle-pressing device: 4-9 is the motor shaft of the noodle...

example example 2

[0041] Example two: Figure 9 to Figure 11 shown.

Embodiment 2

[0042] In the second embodiment, the integration of the noodle pressing box is exactly the same as that of the first embodiment, and the water atomization device is also the same as that of the first embodiment, except that the flour atomization device is different.

[0043] The flour micronizing device of the second embodiment adopts wind force, that is, the flour is micronized by blowing with wind force, and then it is contacted with atomized water for fusion.

[0044] Figure 9 , Figure 10 , Figure 11 Among them, the flour micronization device: 1 is the flour bucket, 2-1 is the fan, 2-2 is the air inlet, 2-3 is the air outlet for blowing the face, 2-4 is the air outlet for the face, and 2-5 is the air outlet for the face.

[0045] The working mode of the noodle machine in Embodiment 2 is: the wind generated by the blower fan 2-1 passes through the air inlet channel 2-2, blows the flour in the noodle bucket 1 from the blowing air outlet 2-3, and the flour is disturbed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com