Multifunctional thermoplasticity aramid fiber bulletproof tablet and bulletproof spine-resistant clothes thereof

A bullet-proof and stab-proof clothing, thermoplastic technology, applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of increasing the quality of bullet-proof clothing, increasing costs, and stacking stiffness, so as to reduce production costs and sales prices, improve Bulletproof function, the effect of improving the broad spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

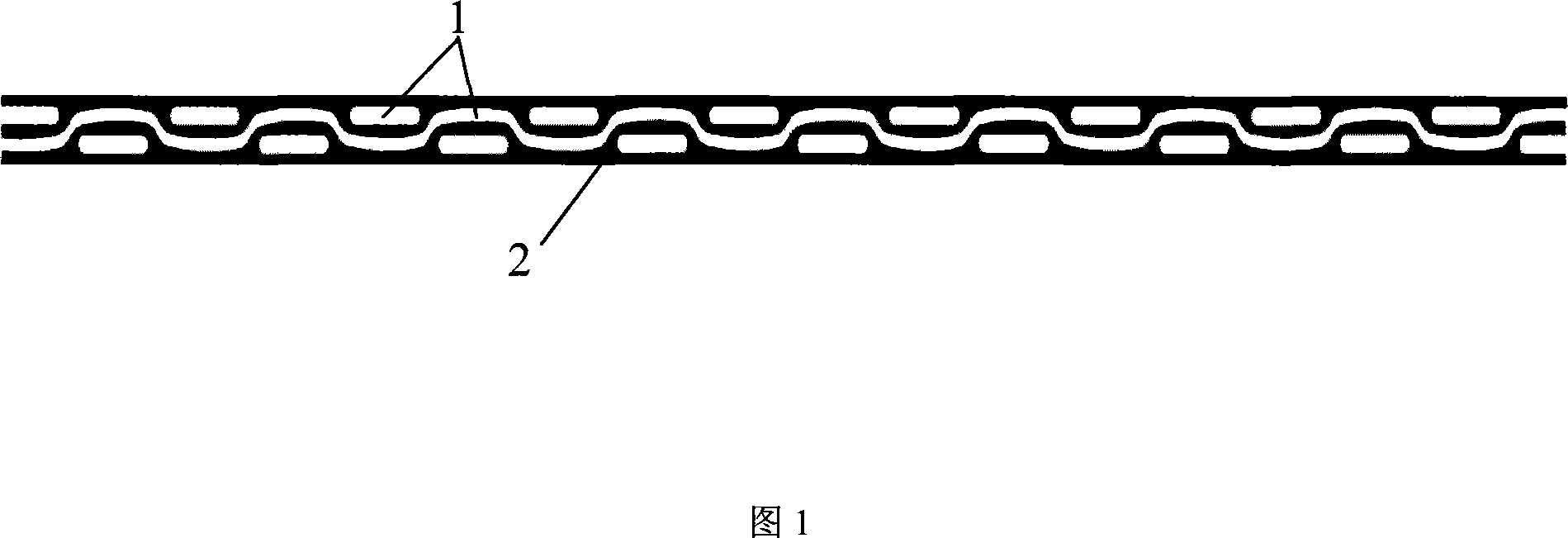

[0022] Example 1: Using aramid bullet-proof cloth 1 and thermoplastic resin 2, composite forming by casting lamination, hot-melt rolling or hot-melt molding, etc., after cooling, it is formed into a multifunctional thermoplastic aramid bullet-proof sheet, and the thermoplastic resin is covered on The surface of the tow of the aramid bulletproof fabric penetrates into the pores of the interweaving point of the tow.

[0023] Aramid bulletproof cloth is an international standard product; the thermoplastic resin is a dark opaque and modified polyethylene elastomer resin.

Embodiment 2

[0024] Example 2: Using aramid bullet-proof cloth 1 and thermoplastic resin 2, composite forming by casting lamination or hot-melt rolling or hot-melt molding, after cooling, it is formed into a multifunctional thermoplastic aramid bullet-proof sheet, and the thermoplastic resin is covered on The surface of the tow of the aramid bulletproof fabric penetrates into the pores of the interweaving point of the tow.

[0025] The aramid bulletproof fabric is an international standard product; the thermoplastic resin is a dark opaque and modified polyvinyl chloride elastomer resin.

Embodiment 3

[0026] Example 3: Using aramid bulletproof cloth 1 and thermoplastic resin 2, composite molding is performed by casting lamination or hot-melt rolling or hot-melt molding, and after cooling, it is formed into a multifunctional thermoplastic aramid bulletproof sheet, and the thermoplastic resin is covered on The surface of the tow of the aramid bulletproof fabric penetrates into the pores of the interweaving point of the tow.

[0027] The aramid bulletproof fabric is an international standard product; the thermoplastic resin is a dark opaque and modified polyurethane elastomer resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com