Clutch face sheet for cars

A technology of clutch face plate and automobile, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., can solve the problems of low anti-rotation burst strength, poor impregnation and adhesion, unstable friction coefficient, etc., to achieve anti-rotation burst The effect of high strength, good impregnation and adhesion, and stable coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

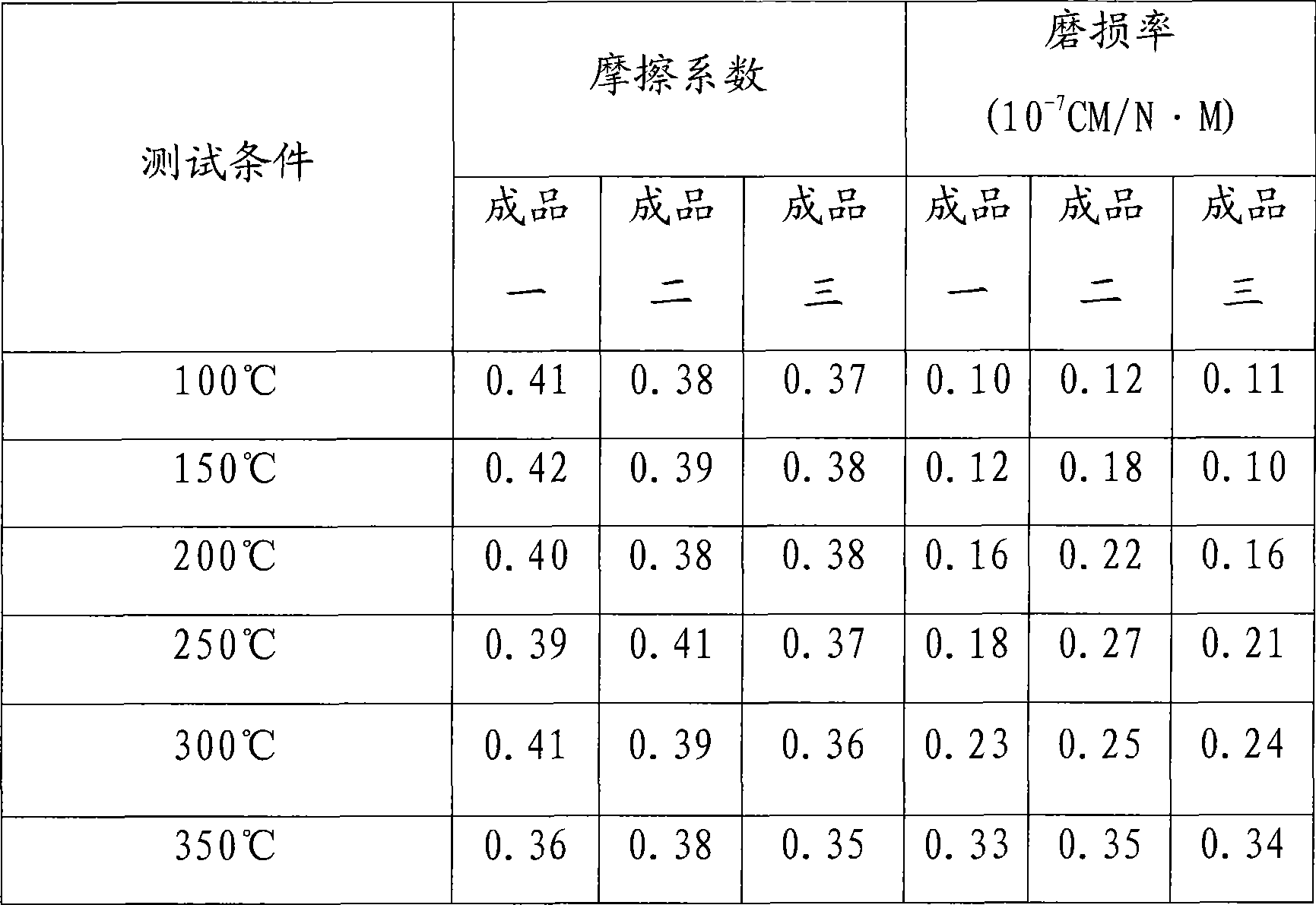

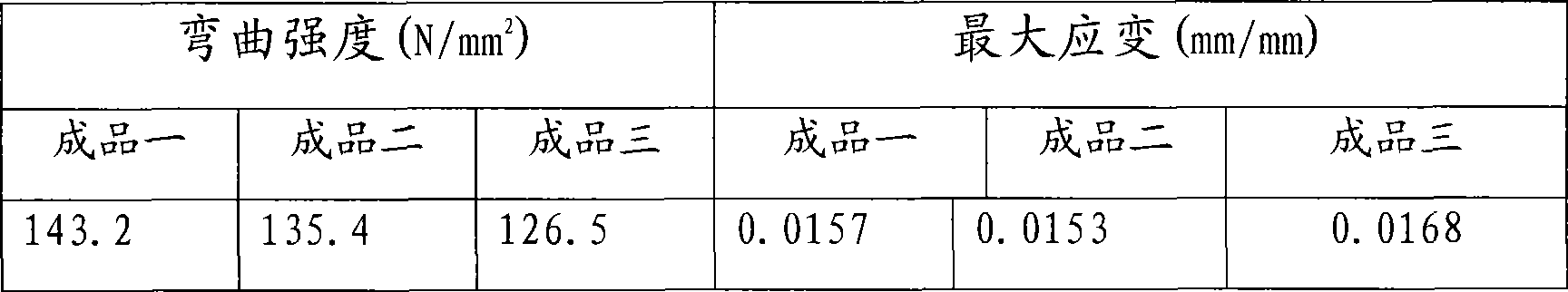

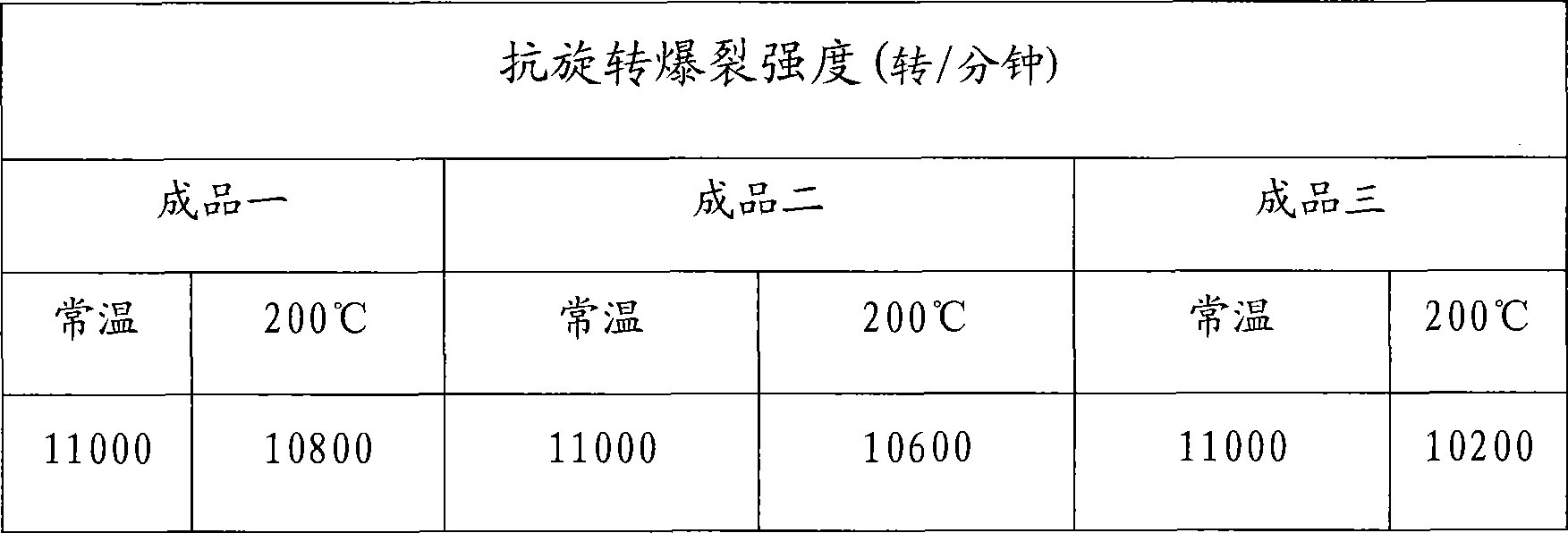

Examples

specific Embodiment approach 1

[0010] Specific embodiment 1: Use subtropical sisal fiber to spun yarn, and then composite aluminum-nickel alloy fiber to weave cord fabric. In this cord fabric, the mass ratio of the subtropical sisal fiber is 90%, and the mass ratio of the aluminum-nickel alloy wire is 10%. Select thermosetting cashew nut shell liquid powdered resin, water-soluble liquid phenolic resin modified by nitrile rubber, and nitrile latex as bonding materials. In the adhesive material, the thermosetting cashew nut shell liquid powdered resin accounts for 27% by mass, the water-soluble liquid phenolic resin modified by nitrile rubber accounts for 53% by mass, and the nitrile rubber latex accounts for The mass ratio is 20%. Use abrasive fillers such as barite, calcium carbonate, cryolite, chromite, and non-abrasive fillers such as antimony sulfide, graphite, and molybdenum disulfide as functional fillers. In the filling material, the mass ratio of the abrasive filler is 85%, and the mass ratio of the non-...

specific Embodiment approach 2

[0011] Specific implementation manner 2: Use subtropical sisal fiber to spun into yarn, and then compound aluminum-nickel alloy wire to weave into cord fabric. In this cord fabric, the mass ratio of the subtropical sisal fiber is 98%, and the mass ratio of the aluminum-nickel alloy wire is 2%. The bonding material, filling material and processing technology are the same as in the first embodiment. In the finished automobile clutch face sheet (hereinafter referred to as "finished product 2"), the above-mentioned cord fabric mainly made of natural subtropical sisal fiber accounts for 31% by mass, binding material accounts for 28% by mass, and filler material accounts for The mass ratio is 41%.

specific Embodiment approach 3

[0012] Specific implementation mode 3: Use subtropical sisal fiber to spun into yarn, and then composite aluminum-nickel alloy wire to weave cord fabric. In this cord fabric, the mass ratio of the subtropical sisal fiber is 96.5%, and the mass ratio of the aluminum-nickel alloy fiber is 3.5%. The bonding material, filling material and processing technology are the same as in the first embodiment. In the finished automobile clutch face sheet (hereinafter referred to as "finished product 3"), the above-mentioned cord fabric mainly made of natural subtropical sisal fiber accounts for 32% by mass, binding material accounts for 27% by mass, and filler material accounts for The mass ratio is 41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com