A kind of high temperature resistant flexible one-component epoxy sealing adhesive and preparation method thereof

A technology of epoxy sealing and high temperature flexibility, applied in epoxy resin glue, adhesives, adhesive additives, etc., can solve the problems of low bonding strength and low yield of silicone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

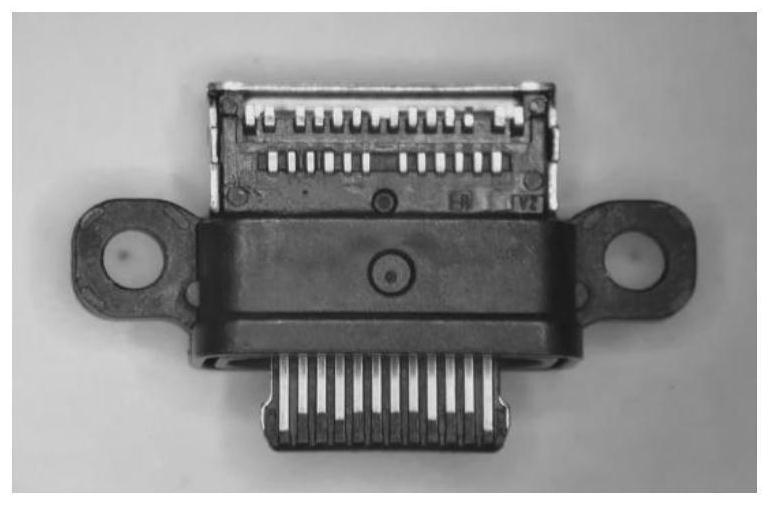

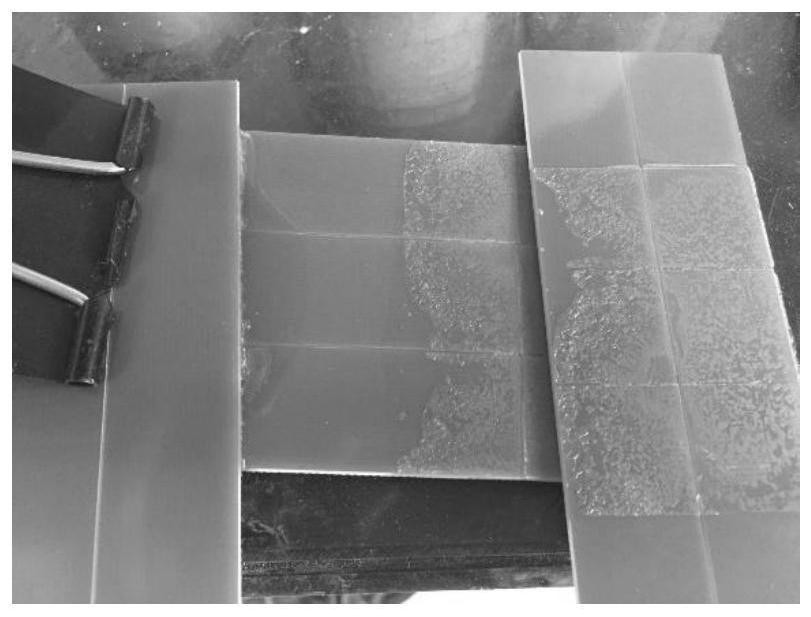

Image

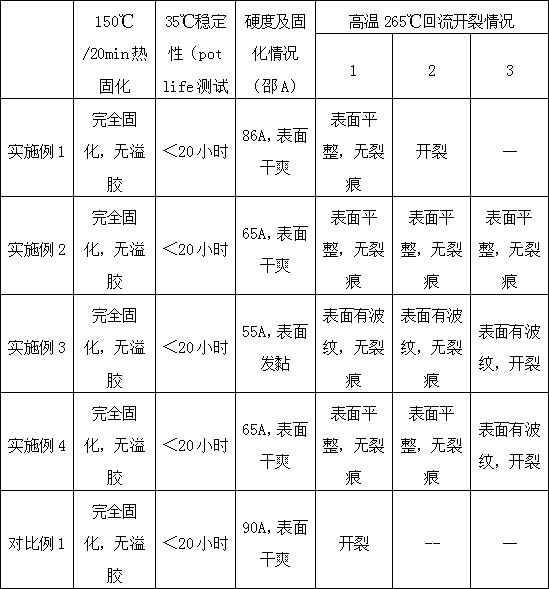

Examples

Embodiment 1

[0072] A high-temperature-resistant flexible one-component epoxy sealing adhesive prepared from the following raw materials in parts by weight:

[0073] Epoxy resin: 20 parts of bisphenol F epoxy resin YLE1300F;

[0074] Softening resin: HEF750 26 parts;

[0075] Softening resin: 4 parts of H2004;

[0076] Reactive diluent: 20 parts of tertiary carbonic acid glycidyl ether E10P;

[0077] Curing agent: 2.6 parts of modified imidazole latent thermal curing agent PN-23;

[0078] Curing agent: modified amine latent thermal curing agent EH-4360S 7 parts;

[0079] Inhibitor: 0.1 part of 2,6-di-tert-butyl-p-cresol BHT;

[0080] Fumed silica: 5 parts of R8200;

[0081] Wetting flow promoter: MEGAFACE F-560 0.3 parts;

[0082] Spherical silica powder: 15 parts of Q010.

[0083] The preparation method of adhesive in the present embodiment comprises the following steps:

[0084] 1) Add epoxy resin, mixed softening resin, fumed silica, and spherical silicon micropowder into the st...

Embodiment 2

[0089] A high-temperature-resistant flexible one-component epoxy sealing adhesive prepared from the following raw materials in parts by weight:

[0090] Epoxy resin: 20 parts of bisphenol F epoxy resin YLE1300F;

[0091] Softening resin: 22 parts of HEF750;

[0092] Softening resin: 8 parts of H2004;

[0093] Reactive diluent: 20 parts of tertiary carbonic acid glycidyl ether E10P;

[0094] Curing agent: 2.6 parts of modified imidazole latent thermal curing agent PN-23;

[0095] Curing agent: modified amine latent thermal curing agent EH-4360S 7 parts;

[0096] Inhibitor: 0.1 part of 2,6-di-tert-butyl-p-cresol BHT;

[0097] Fumed silica: 5 parts of R8200;

[0098] Wetting flow promoter: MEGAFACE F-560 0.3 parts;

[0099] Spherical silica powder: 15 parts of Q010.

[0100] The preparation method of the adhesive in this example is consistent with Example 1.

Embodiment 3

[0102] A high-temperature-resistant flexible one-component epoxy sealing adhesive prepared from the following raw materials in parts by weight:

[0103] Epoxy resin: 20 parts of bisphenol F epoxy resin YLE1300F;

[0104] Softening resin: HEF750 18 parts;

[0105] Softening resin: 12 parts of H2004;

[0106] Reactive diluent: 20 parts of tertiary carbonic acid glycidyl ether E10P;

[0107] Curing agent: 2.6 parts of modified imidazole latent thermal curing agent PN-23;

[0108] Curing agent: modified amine latent thermal curing agent EH-4360S 7 parts;

[0109] Inhibitor: 0.1 part of 2,6-di-tert-butyl-p-cresol BHT;

[0110] Fumed silica: 5 parts of R8200;

[0111] Wetting flow promoter: MEGAFACE F-560 0.3 parts;

[0112] Spherical silica powder: 15 parts of Q010.

[0113] The preparation method of the adhesive in this example is consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com