Method and device for preparing porous ceramic by heavy gas-protective direct-foaming technology

A technology of porous ceramics and foaming devices, applied in ceramic products, applications, household appliances, etc., can solve the problems of difficult polymerization of ceramic slurry, long production experiment cycle, hindering polymerization reaction, etc., and achieve fast gelation speed and stable foam , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

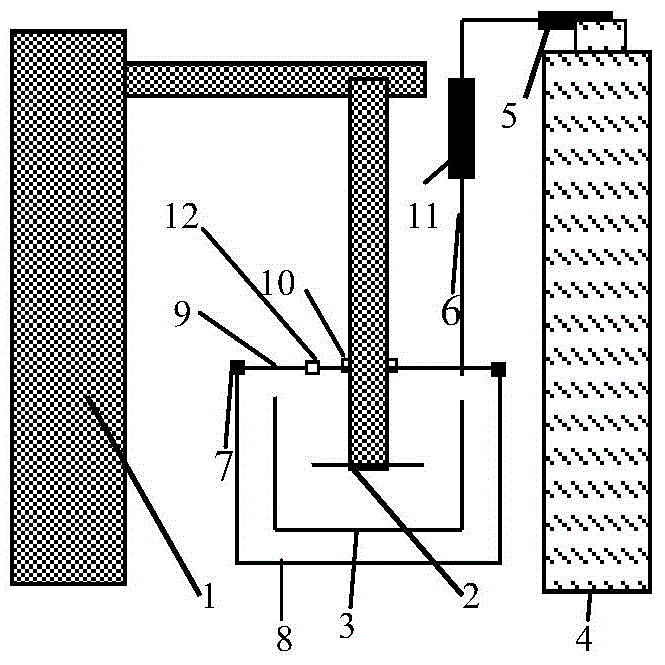

Image

Examples

Embodiment 1

[0024]Weigh 500g of alumina ceramic powder with an average particle size of 0.5μm, add 80ml of deionized water, 10ml of ammonium acrylate dispersant, 10ml of ammonia water (10%), 1g of basic magnesium carbonate powder, and 12g of acrylamide organic monomer , 0.8g methylenebisacrylamide; put the above mixture into a roller mill for 15 hours; Activator 0.5g, put into special foaming equipment, and keep the Ar gas flow rate 500ml / min; after 2min, adjust the rotor speed of the mixer to 1000r / min, and foam the slurry to 500ml; drop in ammonium persulfate aqueous solution (10%) 1.5 g, 1.5 g of tetramethyl-ethylenediammonium (50%) aqueous solution; inject the above-mentioned foamed ceramic slurry into a glass mold; after 1 hour, demould the porous ceramic body and place it on a transparent sieve to dry freely for 10 days ; The dried body is calcined at 1600°C for 2 hours in an air furnace to obtain alumina foam ceramics with a porosity of 65%.

Embodiment 2

[0026] Weigh 500g of silicon nitride ceramic powder with an average particle size of 0.5 μm, 7g of alumina ceramic powder, 7g of yttrium oxide powder, measure 150ml of deionized water, 15ml of ammonium acrylate dispersant, 15ml of ammonia water (10%), 20g Acrylamide organic monomer, 1g methylene bisacrylamide; put the above mixture into a ball mill jar and mill for 15 hours; measure 100ml of ceramic suspension slurry; the slurry is degassed by vacuum stirring until no bubbles overflow, add surface active 0.5g; put the slurry into special foaming equipment, feed Ar gas at 500ml / min for 2min, adjust the mixer speed to 1000r / min, foam the slurry to 500ml, drop in 2ml of ammonium persulfate aqueous solution (10%), Tetramethyl ethylenediammonium (50%) aqueous solution 3ml; The above-mentioned slurry is injected in the glass mould; After 1h, the green body is taken out from the mould, placed on the upper and lower transparent screens and dried for 10 days; The silicon nitride green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com