Injecting paste material for administering soil rising of plate-type ballastless track and preparation method and application method thereof

A technology of slab ballastless track and grouting materials, which is applied in the direction of track, track maintenance, track laying, etc. It can solve the problems of long gel time, poor curing, and inability to bond graded gravel into a whole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

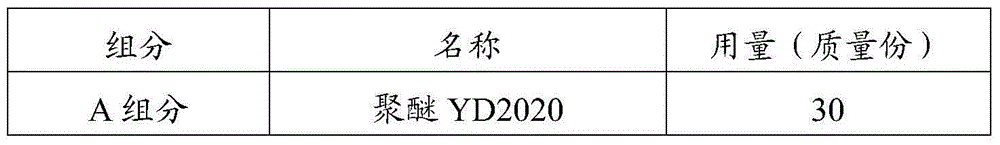

[0062] The preparation process of the plate type ballastless track grouting material of the present invention is as follows (the consumption of each component is shown in Table 1):

[0063] (1) Polyol polyether YD1020 (hydroxyl value 112mgKOH / g), polyether YD4450 (hydroxyl value 350mgKOH / g), crosslinking agent polyether YD303 (hydroxyl value 480mgKOH / g), chain extender 1,4-butyl Diol, plasticizer dibutyl phthalate, polyurethane foam stabilizer AK8805, antioxidant 1010 and silane coupling agent KH560 are put into the reaction kettle in turn, stirred at a speed of 200rpm and heated to 110°C, and then reacted Vacuumize and dehydrate the kettle with a vacuum degree of 0.09MPa, keep it for 3 hours, stop heating, cool down to 40°C, add water, curing accelerator stannous octoate, pentamethyldiethylenetriamine, diluent S1000 solvent naphtha, continue to stir at a speed of 200rpm for 0.5 hour, and then pack and store to obtain the A component.

[0064](2) Stir the isocyanate PAPI (pur...

Embodiment 2

[0073] The preparation process of the slab ballastless track grouting material of the present invention is as in Example 1 (see Table 2 for the dosage of each component).

[0074] The performance of the grouting material of the present invention: A and B components start to react 30s after mixing, the gel foams and solidifies after 90s, the viscosity is 350mPa·s, the expansion pressure is 11.8kPa, the compressive strength is 32MPa, and the elastic modulus It is 153MPa, and the bonding strength is 3.2MPa.

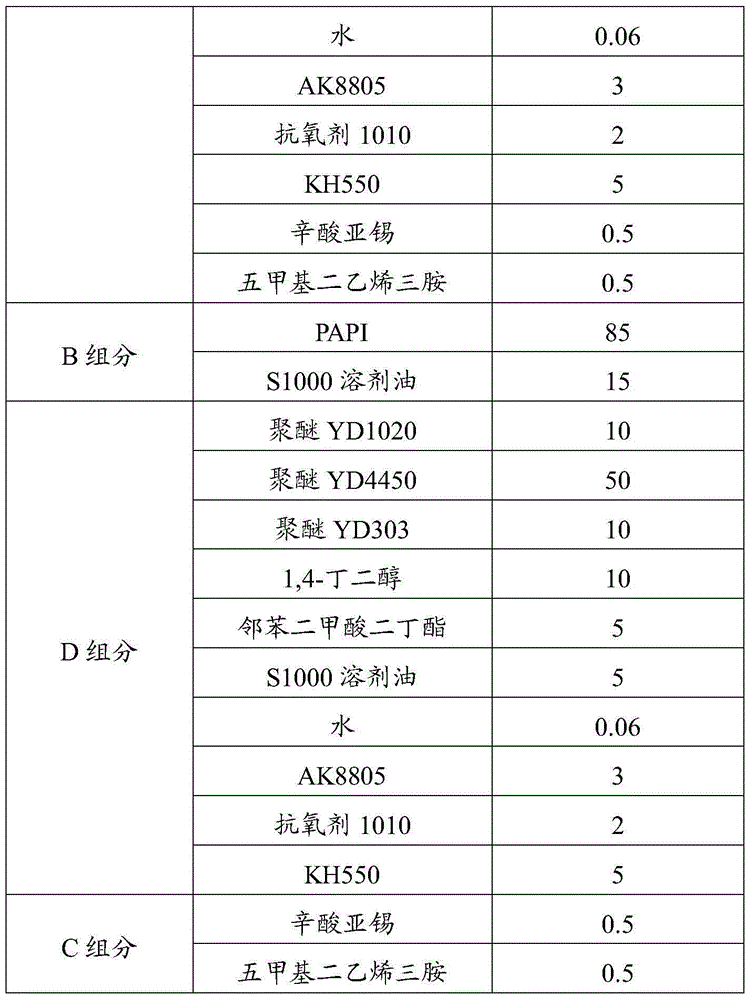

[0075] Table 2: The dosage of each component

[0076]

[0077]

Embodiment 3

[0079] The preparation process of the slab ballastless track grouting material of the present invention is as in Example 1 (see Table 3 for the dosage of each component).

[0080] The performance of the grouting material of the present invention: A and B components start to react 20s after mixing, the gel foams and solidifies after 60s, the viscosity is 350mPa·s, the expansion pressure is 10.4kPa, the compressive strength is 36MPa, and the elastic modulus It is 161MPa, and the bonding strength is 3.8MPa.

[0081] Table 3: The amount of each component

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com