Method for preparing barium titanate compounds

A barium titanate and compound technology, which is applied in the field of preparing barium titanate compounds, can solve the problems of high hydrothermal time, large sample particle size, and low product purity, and achieves simple methods, fast gelation speed, and colloidal Uniform effect throughout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] 1. Synthesis of Barium Titanate

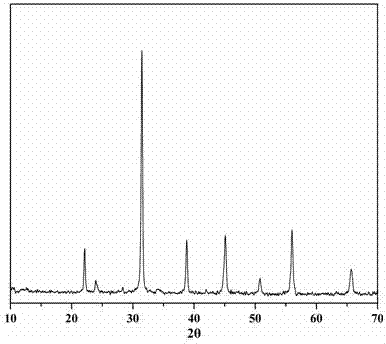

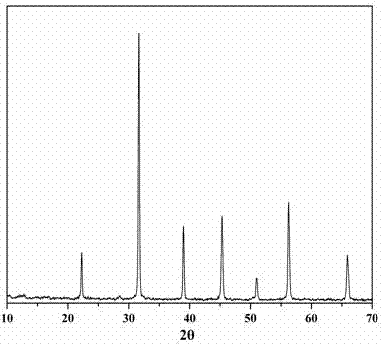

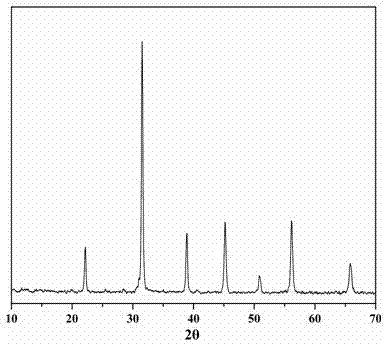

[0014] Dissolve 0.01 mol of tetra-n-butyl titanate in 5 ml of isopropanol, then add 1.5 ml of glacial acetic acid, and stir on a magnetic stirrer. Dissolve 0.01 mole of barium acetate in 10 ml of 36% acetic acid, and add it to the solution of tetra-n-butyl titanate after completely dissolving (it is not necessary to adjust the water content and pH of the solution during this period), and continue on the magnetic stirrer. After stirring for half an hour, put it into a reaction kettle with a volume of 25 ml, put it in a 100°C constant temperature for 2-4 hours after filling the can, and obtain a milky white, uniform jelly-like colloid, and dry it at 100°C for 10 hours. After grinding evenly, put it in a muffle furnace, pre-calcined at 350°C, and calcined at 900°C for 5 hours to obtain a pure white barium titanate compound with a perovskite structure.

[0015] Analysis by X-ray diffraction (XRD), elemental analysis and energy spectrum ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com