Cyanate ester/bimaleimide modified resin and preparation method

A bismaleimide and modified resin technology, applied in the field of high-performance modified resins, can solve the problems of harsh curing equipment and restrictions on the wide application of cyanate/bismaleimide resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

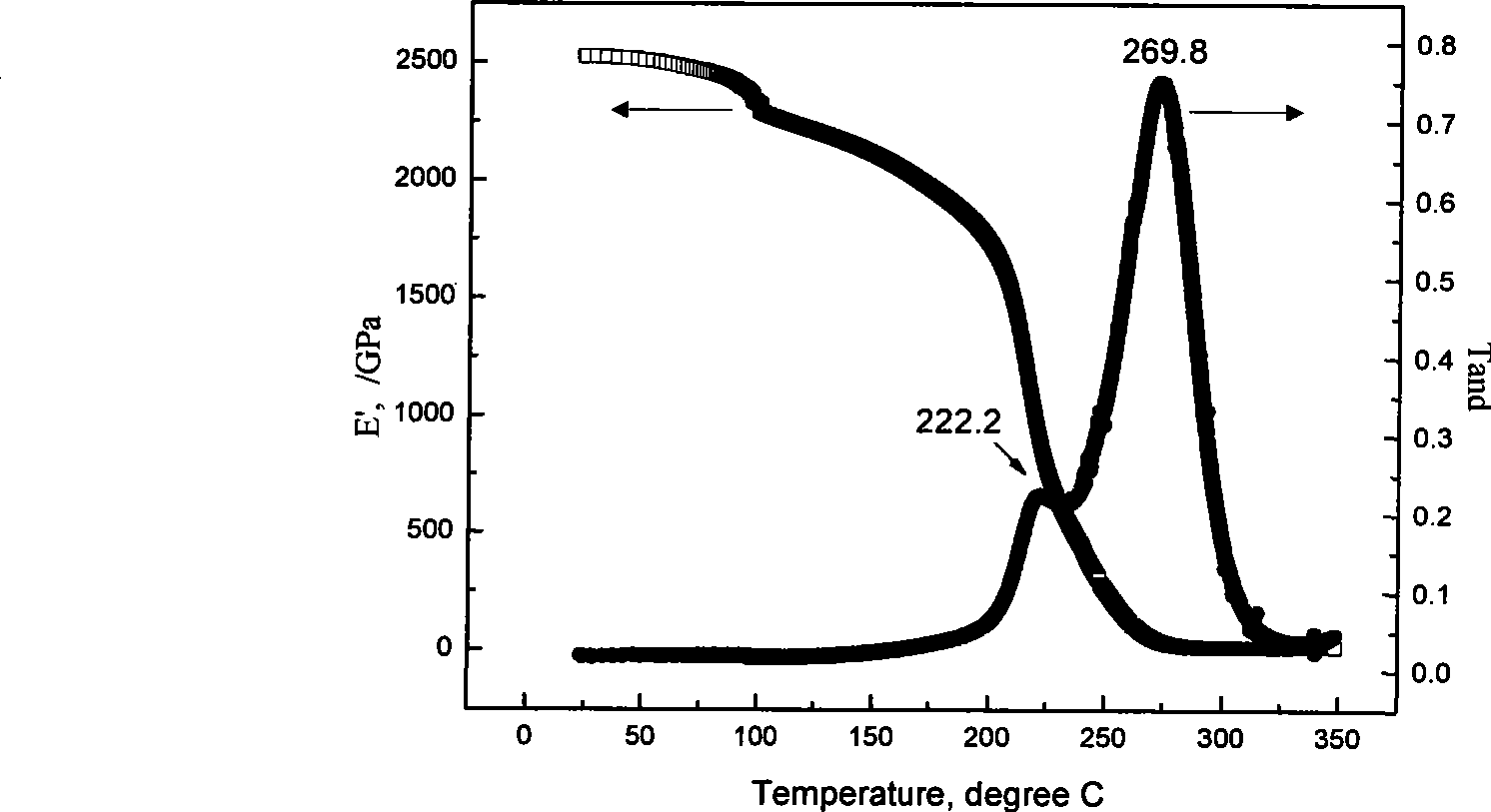

[0018] Bisphenol A type cyanate monomer (BADCy) 90g, 4,4'-diphenylmethane bismaleimide (BDM) 10g (BADCy:BDM=15.6:1mol), heat and melt in an oil bath at 160°C , after stirring evenly, add 4.5g of organotin catalyst, stir and react at this temperature for 20min, then pour it into the mold, degas it in a vacuum drying oven for 5min, put it in an electronic oven for curing according to the predetermined curing process, and post-cure The condition is 220°C / 2h. The properties of the cured resins are listed in Table 1. Dynamic Mechanical Thermal Analysis DMA as figure 1 shown.

Embodiment 2

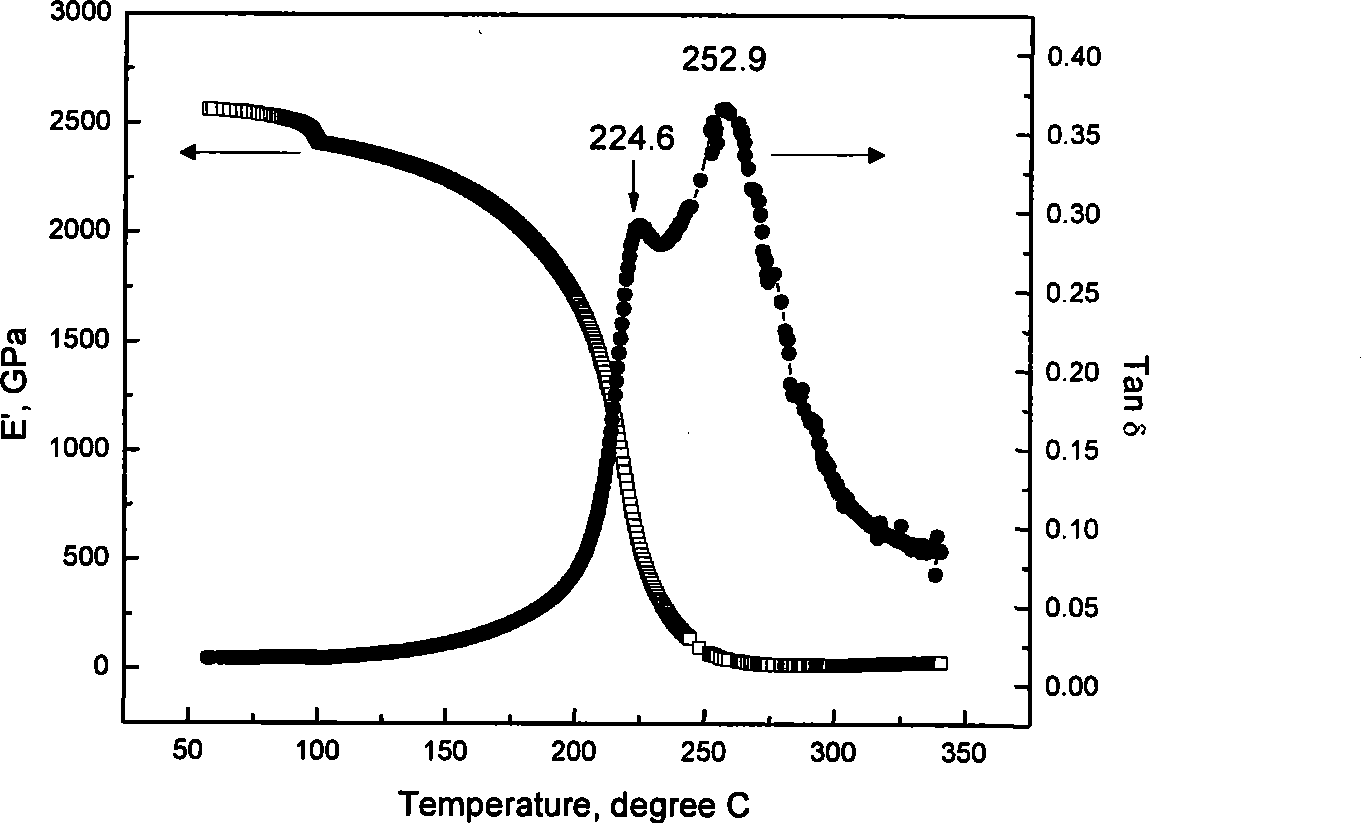

[0020] Bisphenol A type cyanate monomer (BADCy) 30g, 4,4'-diphenylmethane bismaleimide (BDM) 20g (BADCy:BDM=1.93:1mol), heat and melt in an oil bath at 160°C , after stirring evenly, 1.5 g of organotin catalyst was added, and the rest were the same as in Example 1, and the post-curing condition was 220°C / 4h. Dynamic Mechanical Thermal Analysis DMA as figure 2 shown.

Embodiment 3

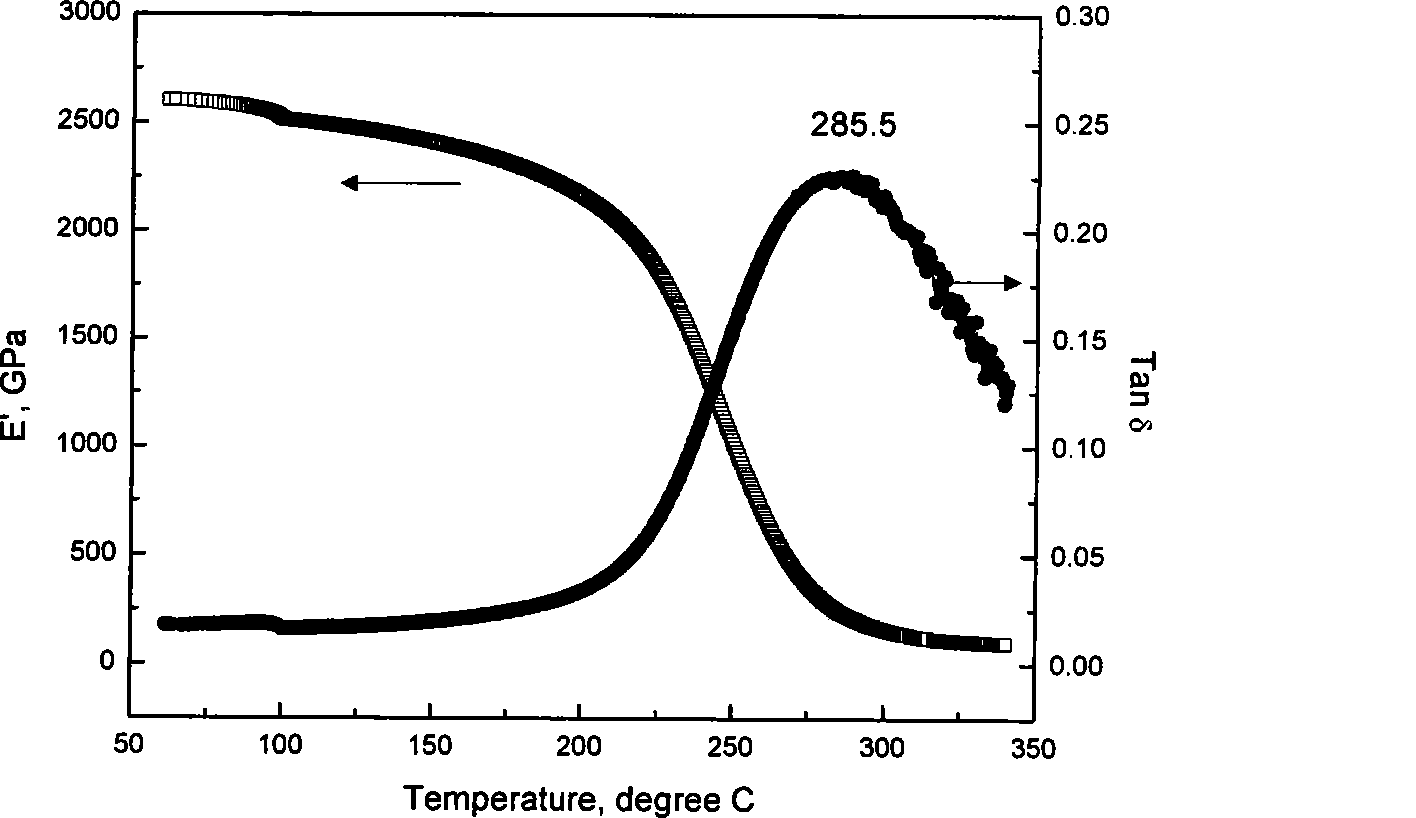

[0022] Bisphenol A type cyanate monomer (BADCy) 22g, 4,4'-diphenylmethane bismaleimide (BDM) 28g (BADCy:BDM=1:1mol), heat and melt in an oil bath at 160°C , add organotin catalyst 2.2g after stirring evenly, all the other are the same as embodiment 2. Dynamic Mechanical Thermal Analysis DMA as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com