Crosslinkable polyphenyl ether resin, preparation method and use thereof

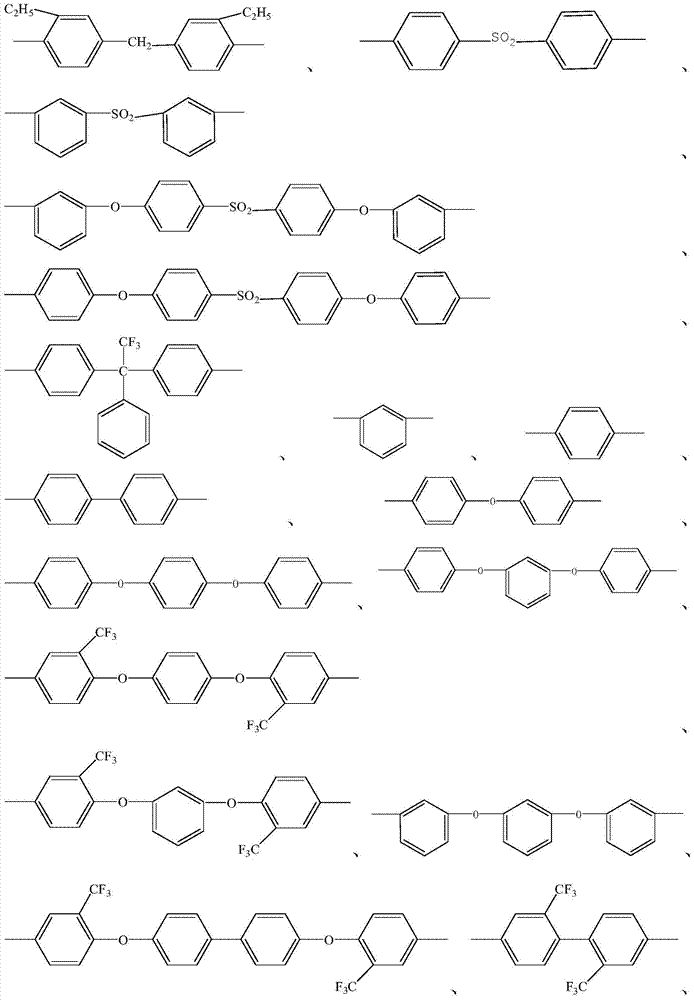

A polyphenylene ether resin and cross-linking technology, which is applied in the field of preparation of cross-linkable polyphenylene ether resin, can solve the problems of poor processing performance, poor compatibility, phase separation, and poor solvent resistance of PPO resin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

[0081] (1) Redistribution of PPO

[0082] Stir and heat 400g of toluene in a three-necked flask equipped with a stirrer, condensing reflux tube, and thermometer to 102°C, then add 100g of PPO resin with a number average molecular weight of 20,000, and add 6g of diallyl bis Phenol A (DABPA), stirred for 30 minutes, then added 7.5 g of tert-butyl peroxyisobutyrate dissolved in toluene, and kept the temperature at 102 ° C, and reacted for 180 minutes.

[0083] (2) Modified PPO reacts with BMI

[0084] In (1), the temperature of the reaction product was raised to 140 degrees Celsius, and 13.9 g of diphenylmethane-type BMI was added. After the BMI was dissolved, the reaction was stopped after 5 hours of reaction, poured out, and cooled.

[0085] Repeating the above operations, changi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com