High temperature resistant halogen-free flame-retardant adhesive for flexible copper clad foil substrate and preparation thereof

A technology of copper-clad substrates and flame-retardant adhesives, which is applied in the direction of adhesives, adhesive types, conjugated diene adhesives, etc., and can solve the problems of poor high temperature resistance, moisture resistance, heat resistance, and substrate performance degradation and other problems, to achieve the effects of reducing adverse effects, improving solubility, and improving high temperature solder resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

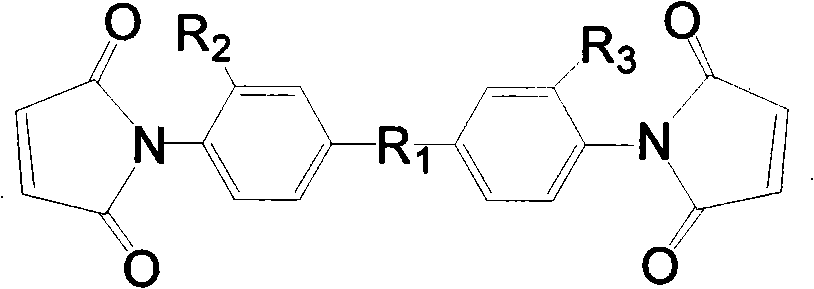

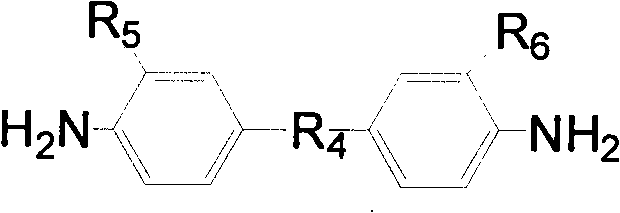

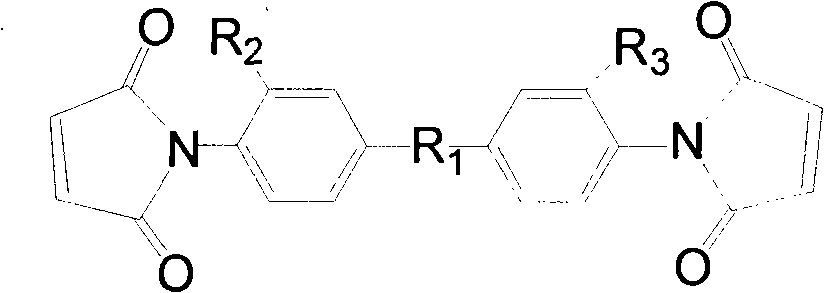

[0060] Embodiment 1. Get 5 grams of bismaleimide (in the bismaleimide structure, R 1 for -O-, R 2 , R 3 Both are -H), 1.42 grams of aromatic diamine (in the structure of aromatic diamine, R 4 for -O-, R 5 , R 6 Both are -H), 0.14 grams of aniline and 10 grams of toluene are heated to transparency in a 100 milliliter three-necked bottle with a stirrer, a condenser and a temperature sensor (industrially it can be enlarged to 100 liters of reactor production). , reacted at reflux temperature for 30 minutes, discharged after cooling, and with 100 gram phosphorus-containing epoxy resin (phosphorus content is 2.55%), 40 gram liquid end carboxyl nitrile rubber, 30 gram phenol type phenolic resin (polymerization degree is 3 ), 40 grams of aluminum hydroxide, 0.2 grams of 2-ethyl-4-methylimidazole, and finally add 200 grams of butanone and mix evenly to obtain a high-temperature-resistant halogen-free flame-retardant adhesive for flexible copper-clad laminates.

[0061] Apply this...

Embodiment 2

[0062] Embodiment 2. Get 2 kilograms of bismaleimide (in the bismaleimide structure, R 1 for -CH 2 -, R 2 , R 3 Both are -H), 0.51 kg of aromatic diamine (in the structure of aromatic diamine, R 4 for -O-, R 5 , R 6 Both are -CH 3 ), 8 grams of aniline and 3 kilograms of toluene were heated to transparency in a 10-liter three-necked flask with a stirrer, a condenser and a temperature sensor, and reacted at reflux temperature for 20 minutes, and discharged after cooling, and mixed with 10 kilograms of Phosphorus epoxy resin (phosphorus content is 3.66%), 3.5 kilograms of liquid carboxy-terminated nitrile rubber, 0.5 kilograms of bisphenol A type phenolic resin (polymerization degree is 4), 4 kilograms of aluminum hydroxide and 1 kilogram of silicon dioxide, 10 grams 2-Methylimidazole, and finally add 25 kg of acetone and 25 kg of methyl ethyl ketone and mix evenly to obtain a high-temperature-resistant halogen-free flame-retardant adhesive for flexible copper-clad laminat...

Embodiment 3

[0064] Embodiment 3. Get 1 kilogram of bismaleimide (in the bismaleimide structure, R 1 for -CH 2 -, R 2 , R 3 Both are -C 2 h 5 ), 0.24 kg of aromatic diamine (in the structure of aromatic diamine, R 4 for -O-, R 5 , R 6 All are-H), 11.1 grams of aniline and 2 kilograms of toluene, after being heated to transparent in 5 liters of three-neck bottles with stirrer, condenser, temperature sensor, react 35 minutes at reflux temperature, discharge after cooling, and With 6.5 kilograms of phosphorus-containing epoxy resin (phosphorus content is 4.3%), 2.5 kilograms of liquid end carboxyl nitrile rubber, 0.13 kilograms of cresol type phenolic resin (polymerization degree is 4), 2.25 kilograms of aluminum hydroxide and 1 kilogram of basic carbonic acid Aluminum sodium, 0.13 kg of 2-ethylimidazole, and finally 20 kg of butanone and 3.4 kg of toluene were added and mixed evenly to obtain a high-temperature-resistant halogen-free flame-retardant adhesive for flexible copper clad l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com