High-toughness flame-retardant medium-and-low-temperature cured epoxy resin system and preparation method thereof

A technology for curing epoxy resin and epoxy resin, applied in the field of advanced polymer material science, can solve problems such as difficulty in ensuring particle dispersion, achieve excellent flame retardant efficiency, improve flame retardant performance, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

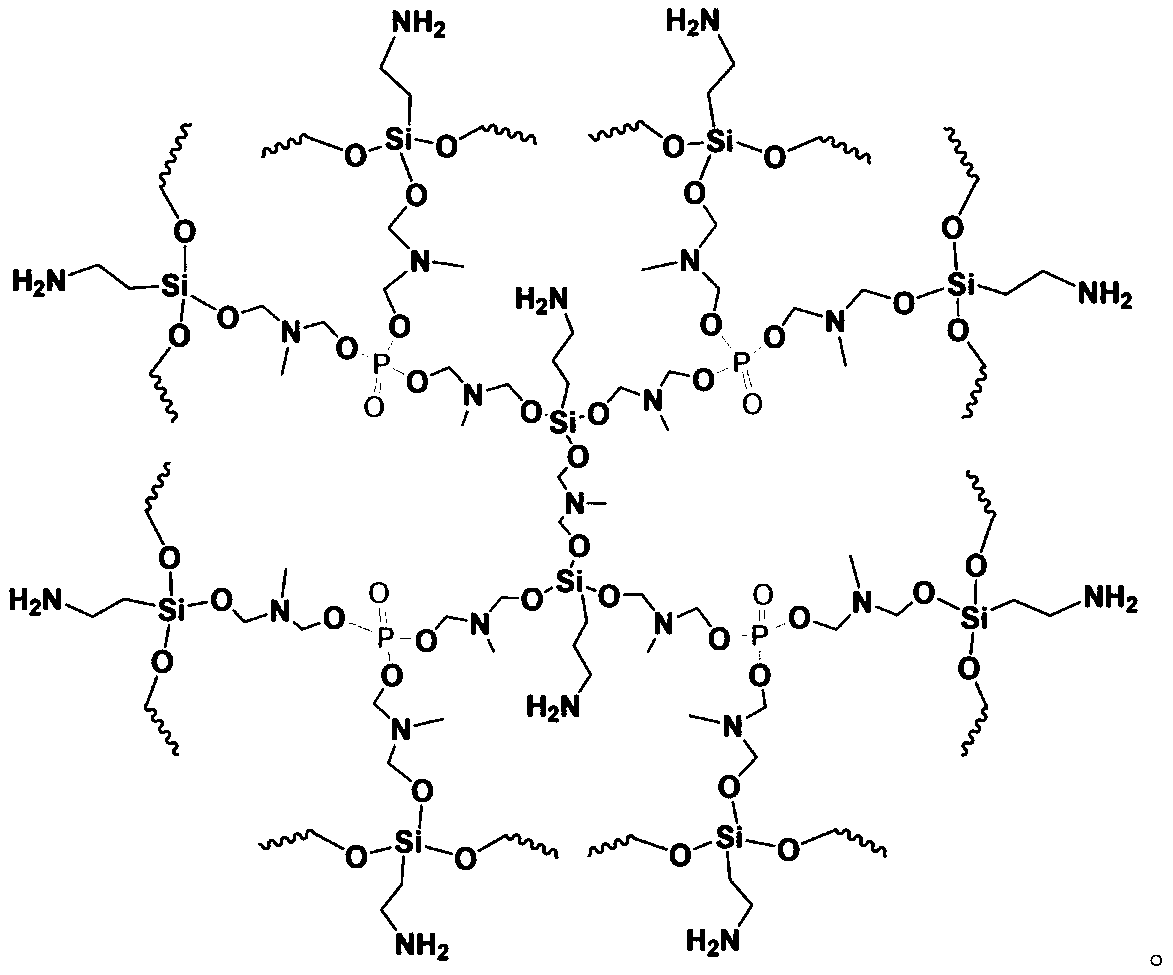

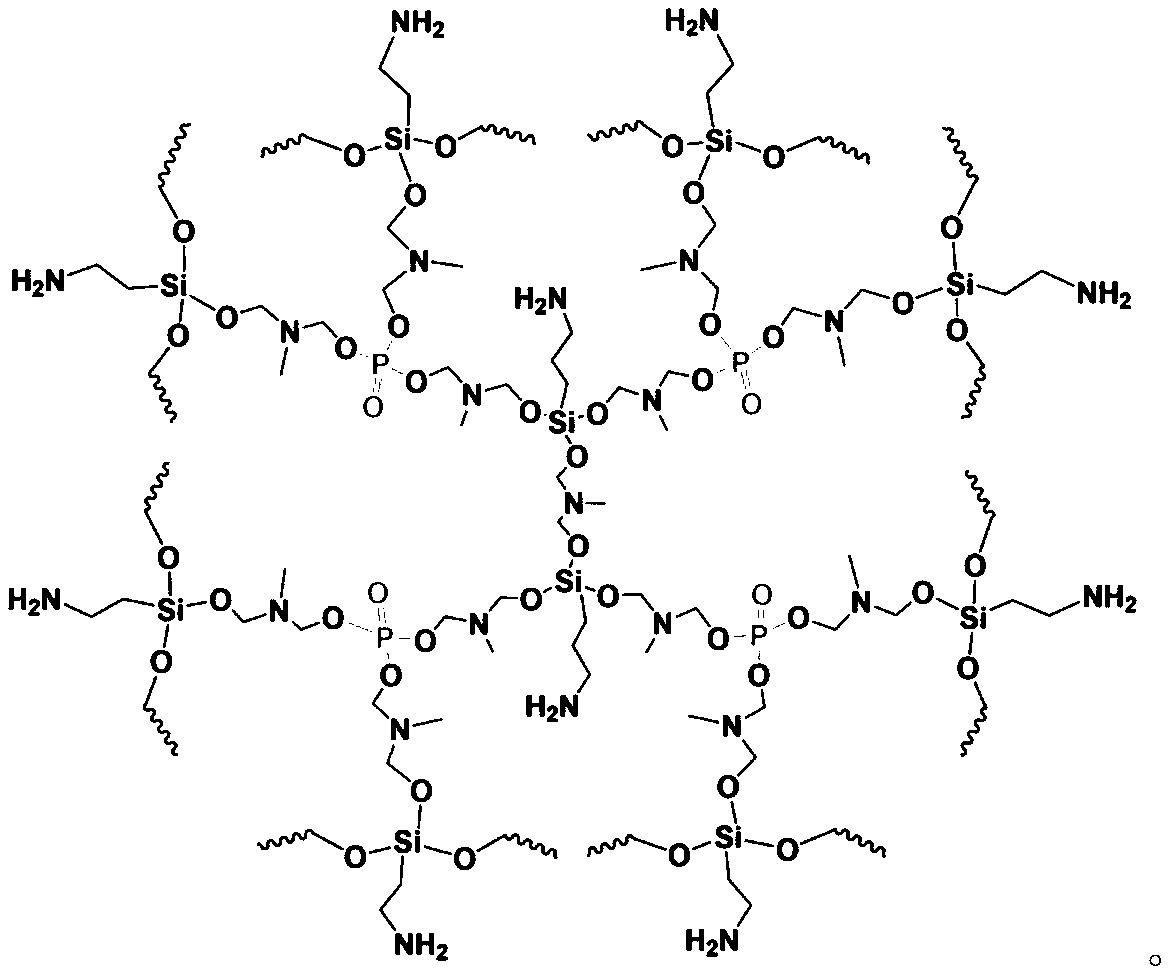

[0032]Add γ-aminopropyltriethoxysilane, triethyl phosphate and N-methyldiethanolamine into a three-necked flask at a molar ratio of 1:1:4.375, and stir in an oil bath under the protection of nitrogen to control the reaction The temperature is between 80-150 DEG C, and the reaction is carried out for 10-12 hours until no distillate is produced to obtain the product hyperbranched polysilicon phosphate.

[0033] Mix 12 parts of bisphenol A epoxy resin and 48 parts of tetraglycidylamine epoxy resin, add 3 parts of hyperbranched polysilicon phosphate, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 60 parts of acid anhydride curing agent into the above-mentioned prepolymer, stir for 5-10 minutes, pour into the preheated mold, vacuumize to remove air bubbles in a vacuum oven at 60-80°C, and put Blast drying oven for staged heating and curing, the curing process is 90~120°C / 2~4h+140~160°C / 2~3h, cooling, after demoulding, and then post-treatment...

Embodiment 2

[0035] Add γ-aminopropyltriethoxysilane, triethyl phosphate and N-methyldiethanolamine into a three-necked flask at a molar ratio of 1:1:4.375, and stir in an oil bath under the protection of nitrogen to control the reaction The temperature is between 80-150 DEG C, and the reaction is carried out for 10-12 hours until no distillate is produced to obtain the product hyperbranched polysilicon phosphate.

[0036] Mix 12 parts of bisphenol A epoxy resin and 48 parts of tetraglycidylamine epoxy resin, add 5 parts of hyperbranched polysilicon phosphate, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 60 parts of acid anhydride curing agent into the above-mentioned prepolymer, stir for 5-10 minutes, pour into the preheated mold, vacuumize to remove air bubbles in a vacuum oven at 60-80°C, and put Blast drying oven for staged heating and curing, the curing process is 90~120°C / 2~4h+140~160°C / 2~3h, cooling, after demoulding, and then post-treatmen...

Embodiment 3

[0038] Add γ-aminopropyltriethoxysilane, triethyl phosphate and N-methyldiethanolamine into a three-necked flask at a molar ratio of 1:1:4.375, and stir in an oil bath under the protection of nitrogen to control the reaction The temperature is between 80-150 DEG C, and the reaction is carried out for 10-12 hours until no distillate is produced to obtain the product hyperbranched polysilicon phosphate.

[0039] Mix 20 parts of bisphenol A epoxy resin and 40 parts of tetraglycidylamine epoxy resin, add 3 parts of hyperbranched polysilicon phosphate, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 60 parts of acid anhydride curing agent into the above-mentioned prepolymer, stir for 5-10 minutes, pour into the preheated mold, vacuumize to remove air bubbles in a vacuum oven at 60-80°C, and put Blast drying oven for staged heating and curing, the curing process is 90~120°C / 2~4h+140~160°C / 2~3h, cooling, after demoulding, and then post-treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com