Polyphenyl ether resin composition and application thereof

A technology of polyphenylene ether resin and composition, which is applied in synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of insufficient curing and crosslinking, high viscosity, poor processing performance, etc. Storage stability, high Tg, toughness enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 comparative example 1-3

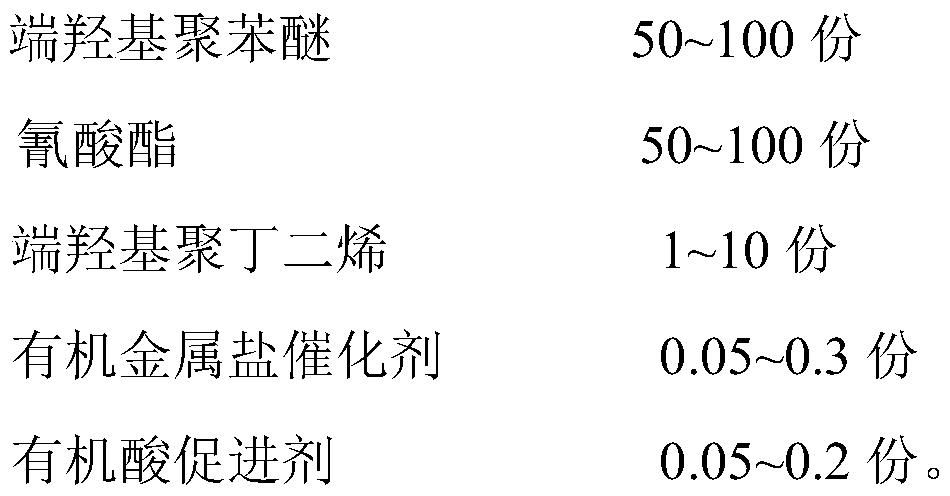

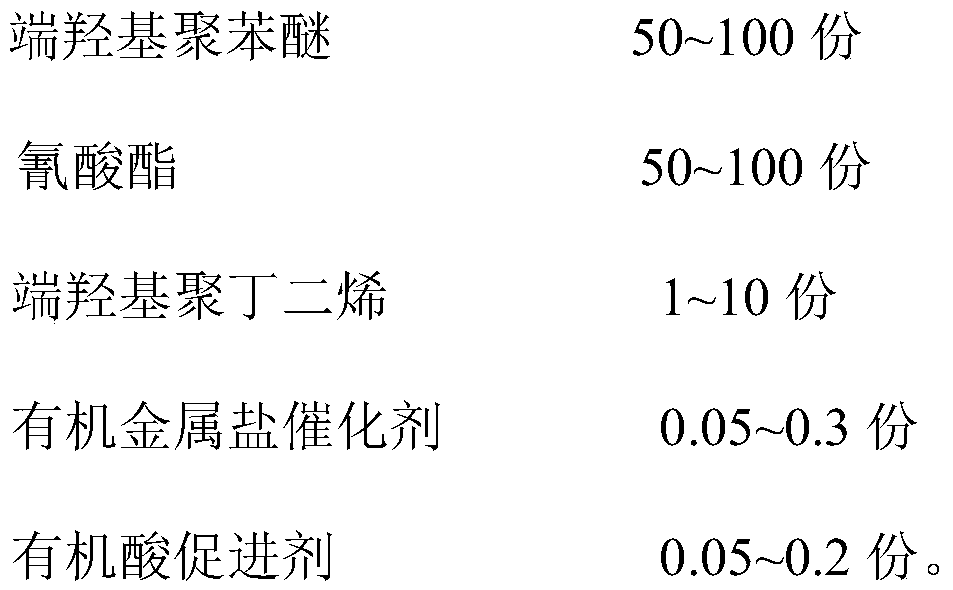

[0046] Fully dissolve hydroxyl-terminated polyphenylene ether, cyanate resin, and hydroxyl-terminated polybutadiene in toluene solution, and then mix them evenly with inorganic filler, flame retardant, organic metal salt catalyst, and organic acid accelerator to obtain polyphenylene ether Toluene solution of the resin composition.

[0047] Immerse the NE glass cloth (Nittobo Co., Ltd., NEA2116) into the resin composition, and bake it at 120°C for 8 minutes to remove the solvent, so that the volatile matter is less than 1%, and the gel time of the resin is about 160s to obtain the resin A prepreg with a content of about 65%.

[0048] Cover each side of 8 overlapping prepregs with an inverted copper foil, hot press at 180°C and a pressure of 3.0MPa for 90min, and then press at 220°C for 120min to obtain a double-sided copper-clad laminate .

[0049] Polyphenylene ether SA90 and cyanate resin CE01MO are common models on the market.

[0050] Wherein specific embodiment result i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com