Attapulgite-clay-based electromagnetic wave absorber in metal-surface-coated electromagnetic wave-absorbing coating and preparation method of attapulgite-clay-based electromagnetic wave absorber

A wave-absorbing coating and metal surface technology, applied in coatings and other directions, can solve the problems of easy agglomeration, loss, and aerodynamic performance degradation of wave-absorbing materials, and achieve the effects of excellent wave-absorbing performance, strong absorption, and spectral bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

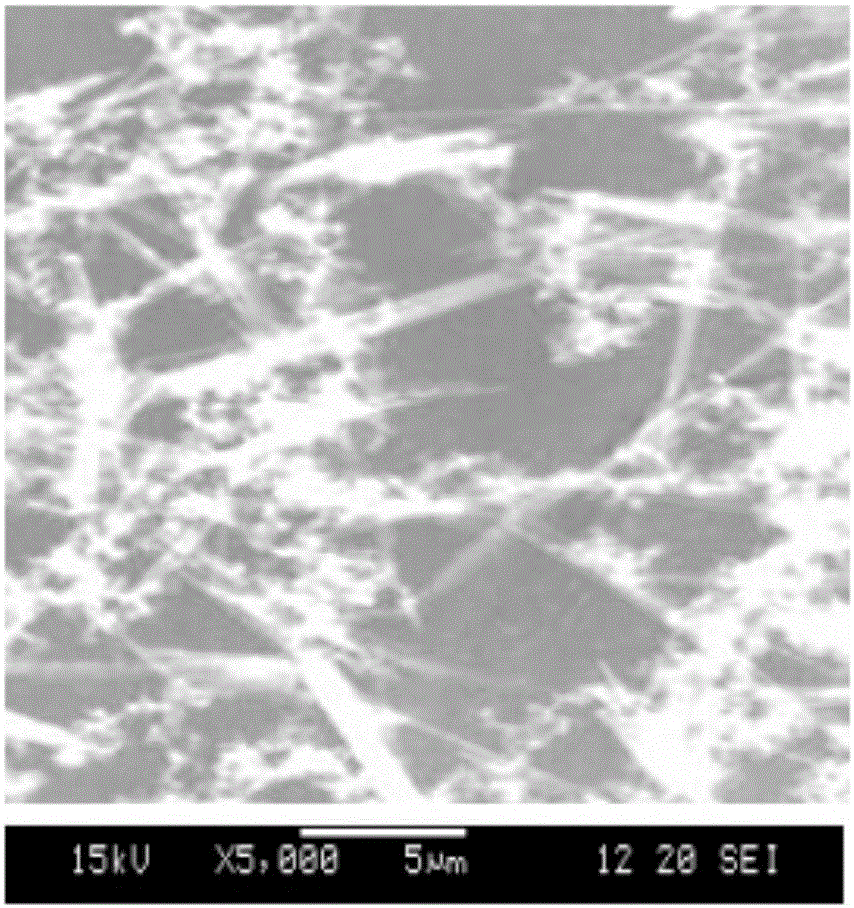

Image

Examples

preparation example Construction

[0021] An attapulgite-based wave-absorbing agent for metal surface coating, the preparation method comprising the following process steps:

[0022] 1. Weigh 100g of attapulgite clay with a fineness of 200-400 mesh, put it into 800-1000ml distilled water and stir it with a stirrer for 2-4 hours, and treat it with 50-100ml hydrochloric acid with a solubility of 1mol / L at 80-100°C 1 to 3 hours; add 5 to 10 ml of compound active agent to the treated suspension, then dropwise add NaOH solution to adjust the pH value of the suspension to 6 to 8, and then stir with a cross blade stirrer at 1500 rpm for 2 ~4 hours, after standing for 10 hours, the attapulgite clay suspension was separated;

[0023] 2. Add 10 to 20 g of carbon nanotubes to the above-mentioned separated attapulgite clay suspension, utilize the active adsorption of carbon nanotubes on the surface of the attapulgite, and stir for 10 to 30 minutes to obtain the attapulgite clay suspension;

[0024] 3. Add 10-20 g of sodiu...

Embodiment 1

[0030] 1. Weigh 100g of attapulgite clay with a fineness of 200 mesh, put it into 1000ml distilled water and stir it with a stirrer for 2 hours, and treat it with 100ml hydrochloric acid with a solubility of 1mol / L at 80-100°C for 2 hours; Add 5ml of composite active agent to the solution, the composite active agent includes organopolysiloxane and OP-10, then add dropwise NaOH solution to adjust the pH value of the suspension to 8, and then use a cross blade stirrer at 1500 rpm After stirring for 4 hours, after standing still for 10 hours, the attapulgite clay suspension was separated;

[0031] 2. Add 20 g of carbon nanotubes to the attapulgite clay suspension separated above, and use the active adsorption of carbon nanotubes on the surface of the attapulgite to obtain the attapulgite clay suspension after stirring for 30 minutes;

[0032] 3. Add 1 g of sodium hexametaphosphate and 30 g of nickel sulfate to 500 ml of deionized water, titrate ammonia water to adjust the pH=8.5 ...

Embodiment 2

[0037] 1. Weigh 100g of attapulgite clay with a fineness of 400 mesh, put it into 900ml distilled water and stir it with a stirrer for 3 hours, and treat it with 80ml hydrochloric acid with a solubility of 1mol / L at 8°C for 2 hours; add the treated suspension to The compound active agent of 8ml, described compound active agent comprises stearic acid and OP-10, then add dropwise NaOH solution to adjust the pH value of suspension to 8, then stir with cross blade stirrer with 1500 rev / min for 4 hours, After standing still for 10 hours, the attapulgite clay suspension was separated;

[0038] 2. Add 15 g of carbon nanotubes to the above-mentioned separated attapulgite clay suspension, utilize the active adsorption of carbon nanotubes on the surface of the attapulgite, and after stirring for 30 minutes, obtain the attapulgite clay suspension;

[0039] 3. Add 20 g of sodium hexametaphosphate and 30 g of nickel sulfate in 500 ml of deionized water, titrate ammonia water to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com