Method for modifying attapulgite clay

A modified technology of attapulgite clay, which is applied in the treatment of dyed low-molecular organic compounds, fibrous fillers, dyed organic silicon compounds, etc. It can solve the problems of system thickening and water-based coatings losing performance, and achieve good dispersion. , the effect of inhibiting the polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

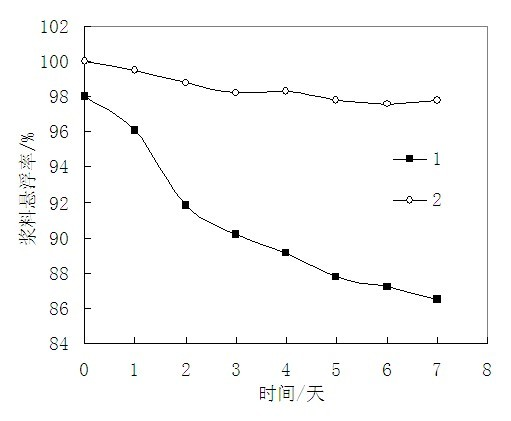

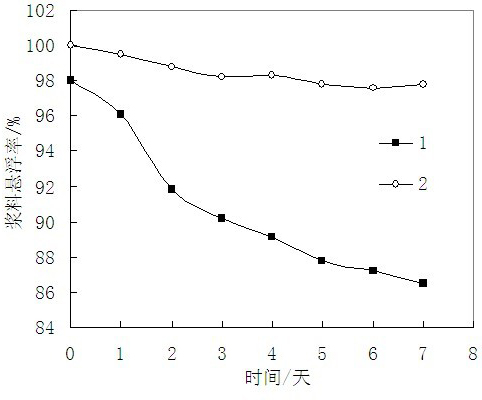

Image

Examples

Embodiment 1

[0017] 1) Soak 50g attapulgite powder (fineness of 200-300 mesh) and 5g stearic acid in 100ml ethanol solution, stir continuously for 4 hours, and then stand for 2 hours;

[0018] 2) Add 2ml of Tween 80 nonionic surfactant to the above mixture, stir and heat it in a 60℃ water bath for 3 hours;

[0019] 3) Filter the mixture, filter out the attapulgite powder and wash it with anhydrous ethanol solution 4 times;

[0020] 4) Dry the cleaned attapulgite powder at 80°C for 5 hours to obtain outstanding attapulgite powder.

Embodiment 2

[0022] 1) Soak 100g of attapulgite powder (with a fineness of 300 mesh to 400 mesh) and 15g of stearic acid in 100ml of toluene solution, stir continuously for 4 hours, and then stand for 2 hours;

[0023] 2) Add 4ml of Tween 20 non-ionic surfactant to the above mixture, stir and heat in a water bath at 80°C for 5 hours;

[0024] 3) Filter the mixture, filter out the attapulgite powder and wash it with anhydrous ethanol solution 4 times;

[0025] 4) Dry the cleaned attapulgite powder at 100°C for 2 hours to obtain outstanding attapulgite powder.

Embodiment 3

[0027] 1) Soak 50g of attapulgite powder (with a fineness of 300 to 400 mesh) and 5g of epoxy polysiloxane in 120ml of a mixed solution of xylene and isopropanol (the ratio of xylene and isopropanol is 78.5 vol%: 21.5vol%), keep stirring for 2 hours, and then stand for 3 hours;

[0028] 2) Add 2ml of Tween 80 non-ionic surfactant to the above mixture, stir and heat in a 60℃ water bath for 7 hours;

[0029] 3) Filter the mixture, filter out the attapulgite powder and wash it with anhydrous ethanol solution 4 times;

[0030] 4) Dry the cleaned attapulgite powder at 80°C for 4 hours to obtain outstanding attapulgite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com