Method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion

A technology for catalytic conversion and cyclopentenone, applied in chemical instruments and methods, preparation of heterocyclic compounds, organic chemistry, etc., can solve problems such as poor stability, improve dehydrogenation performance, selectively promote, and inhibit partial polymerization reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

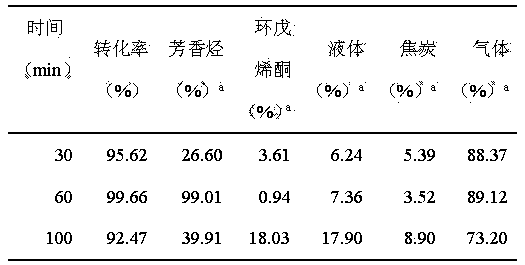

[0023] GVL aromatization: The thermal decomposition of GVL was carried out in a tubular reactor made of quartz glass, and the experimental results are shown in Table 1.

[0024] Table 1 The reaction results of GVL under various catalysts

[0025]

[0026] Reaction conditions: reaction temperature, 500 °C; catalyst, 0.5 g; GVL, 2.5 g (flow rate 2.4 ml / h) and N 2 , 30 ml / min; reaction time: 60 min.

[0027] Carbon Yield%

[0028] It can be seen from Table 1 that Zn / ZSM-5 can obtain 99.53% aromatic hydrocarbon yield, and HZSM-5 can obtain 10.83% cyclopentenone yield.

Embodiment 2

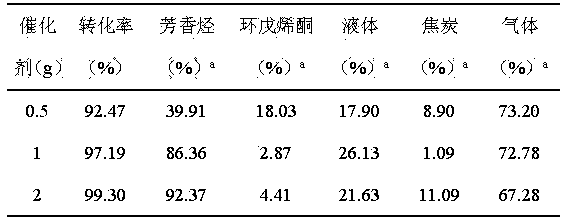

[0030] The GVL aromatization method is the same as in Example 1, except that 1.3% Zn / ZSM-5 is selected as the catalyst, and the influence of different catalyst dosages on the reaction yield is investigated. The experimental results are shown in Table 2.

[0031] Table 2 Effect of catalyst dosage on GVL catalytic conversion products

[0032]

[0033] Reaction conditions: reaction temperature, 500 ℃; catalyst 1.3%Zn / ZSM-5; GVL, 4.6 g (flow rate 2.4 ml / h); N 2 , 30 ml / min; reaction time: 100 min.

[0034] Carbon Yield %.

[0035] It can be seen from Table 2 that when the amount of catalyst used increases gradually, the conversion rate of the product increases, the yield of aromatics increases, the yield of cyclopentenone first decreases and then increases, the percentage of liquid products increases first and then decreases, and the percentage of gas gradually increases. reduce.

Embodiment 3

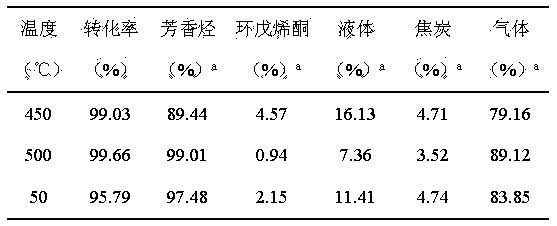

[0037] The GVL aromatization method is the same as in Example 1, except that 1.3% Zn / ZSM-5 is selected as the catalyst, and the yield of the product at different temperatures is investigated. The experimental results are shown in Table 3.

[0038] Table 3 Catalytic conversion of GVL at different temperatures

[0039]

[0040] Reaction conditions: Catalyst 1.3%Zn / ZSM-5, 0.5 g; GVL, 2.5 g (flow rate 2.4 ml / h) and N 2 , 30 ml / min; reaction time: 60 min.

[0041] Carbon Yield %.

[0042] It can be seen from Table 3 that, generally, at 450 °C, the GVL conversion and the yield of aromatics are lower, and the yield of aromatics increases at higher temperatures. Generally, at 500°C, the highest yield of aromatic products is obtained. However, at 550 °C, the yield of aromatics starts to decrease, because aromatics at this temperature can also undergo thermal decomposition, resulting in more gas products. The yields of benzene and toluene increased gradually, while the yields of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com