Preparation method and application of bimetallic catalyst for preparing alanine through lactic acid amination

A bimetallic catalyst, alanine technology, applied in catalyst activation/preparation, preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of single reaction catalytic system, difficult catalyst separation, recycling Using problems such as poor utilization to achieve the effects of simple reaction operation, strong applicability and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

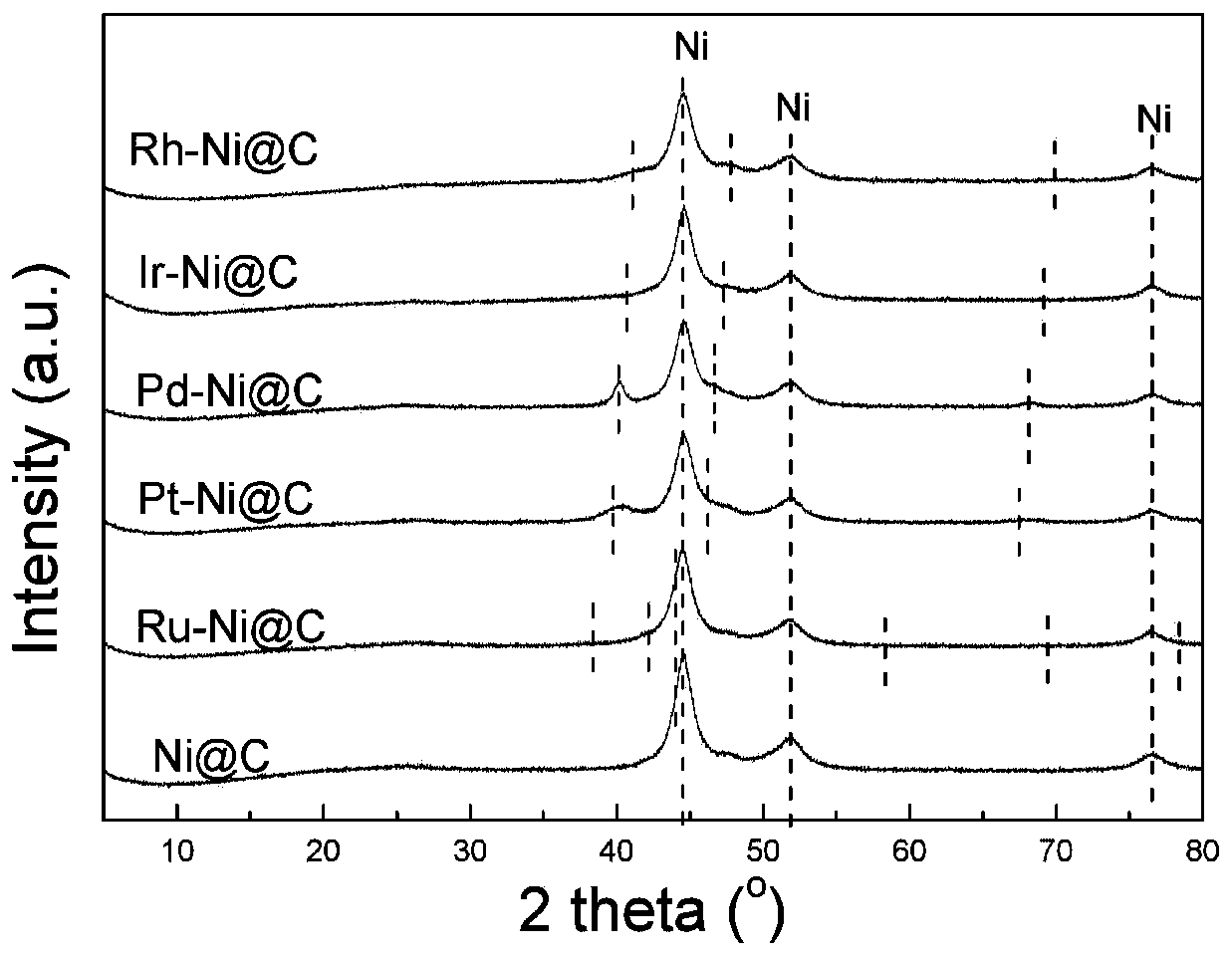

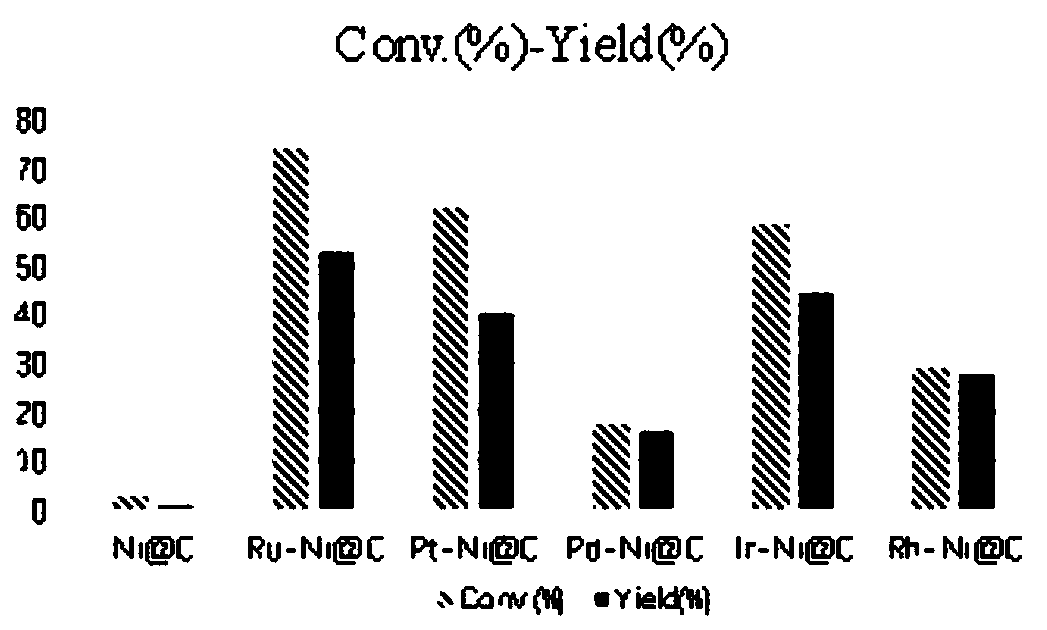

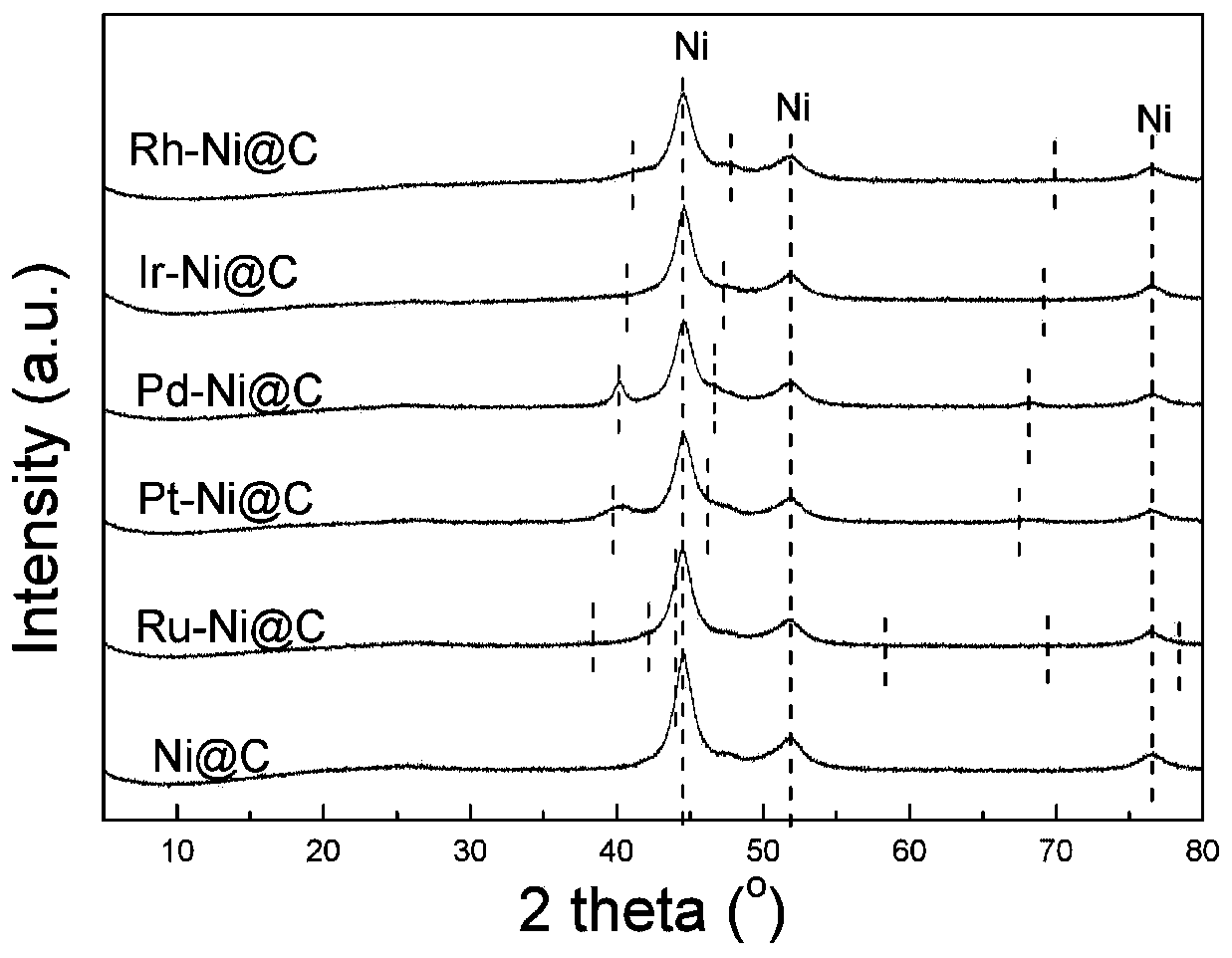

[0025] Example 1: Preparation of magnetic bimetallic catalyst Ru-Ni@C

[0026] Include the following steps:

[0027] Preparation of catalyst precursor CA-Ni: 17.8gNi(NO 3 ) 2 ·6H 2 O, 11.72g of citric acid was dissolved in 5mL of water, stirred at 60°C for 6h to gel, and then placed in a vacuum oven at 60°C for 8h to obtain catalyst precursor powder CA-Ni;

[0028] Preparation of single metal catalyst Ni@C: put catalyst precursor powder CA-Ni in 30mL / min N 2 Calcined at 600°C for 4 hours in the air flow, reduction carbonization reaction occurs, and the heating rate is 2°C / min. The calcined catalyst was taken out and poured into 1mol / L sulfuric acid solution, and stirred at 70°C for 12 hours to wash away insufficiently encapsulated nickel particles. The acid-washed catalyst was fully washed several times in distilled water to achieve neutrality, and then dried in a vacuum freeze dryer to obtain a single metal catalyst Ni@C;

[0029] Preparation of bimetallic catalyst Ru-N...

Embodiment 2

[0030] Example 2: Preparation of magnetic bimetallic catalyst Pt-Ni@C

[0031] Include the following steps:

[0032] Preparation of catalyst precursor CA-Ni: 17.8g Ni(NO 3 ) 2 ·6H 2 O, 11.72g of citric acid was dissolved in 5mL of water, stirred at 60°C for 6h to gel, and then dried in a vacuum oven at 60°C for 8h to obtain the precursor powder CA-Ni;

[0033] Preparation of single metal catalyst Ni@C: put catalyst precursor powder CA-Ni in 30mL / min N 2 Roast at 600°C for 4 hours in airflow, with a heating rate of 2°C / min. The calcined catalyst was taken out and poured into 1mol / L sulfuric acid solution, and stirred at 70°C for 12 hours to wash away insufficiently encapsulated nickel particles. The acid-washed catalyst was fully washed several times in distilled water to achieve neutrality, and then dried in a vacuum freeze dryer to obtain a single metal catalyst Ni@C;

[0034] Preparation of bimetallic catalyst Pt-Ni@C: add H in a three-necked flask 2 PtCl 6 ·6H 2 O ...

Embodiment 3

[0035] Example 3: Preparation of magnetic bimetallic catalyst Pd-Ni@C

[0036]Include the following steps:

[0037] Preparation of catalyst precursor CA-Ni: 17.8g Ni(NO 3 ) 2 ·6H 2 O, 11.72g of citric acid was dissolved in 5mL of water, stirred at 60°C for 6h to gel, and then dried in a vacuum oven at 60°C for 8h to obtain the precursor powder CA-Ni;

[0038] Preparation of single metal catalyst Ni@C: put catalyst precursor powder CA-Ni in 30mL / min N 2 Roast at 600°C for 4 hours in airflow, with a heating rate of 2°C / min. The calcined catalyst was taken out and poured into 1mol / L sulfuric acid solution, and stirred at 70°C for 12 hours to wash away insufficiently encapsulated nickel particles. The acid-washed catalyst was fully washed several times in distilled water to achieve neutrality, and then dried in a vacuum freeze dryer to obtain a single metal catalyst Ni@C;

[0039] Preparation of bimetallic catalyst Pd-Ni@C: adding PdCl to a three-necked flask 2 0.025g (the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com