AEI composite molecular sieve catalyst and preparation method and application thereof

A composite molecular sieve and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

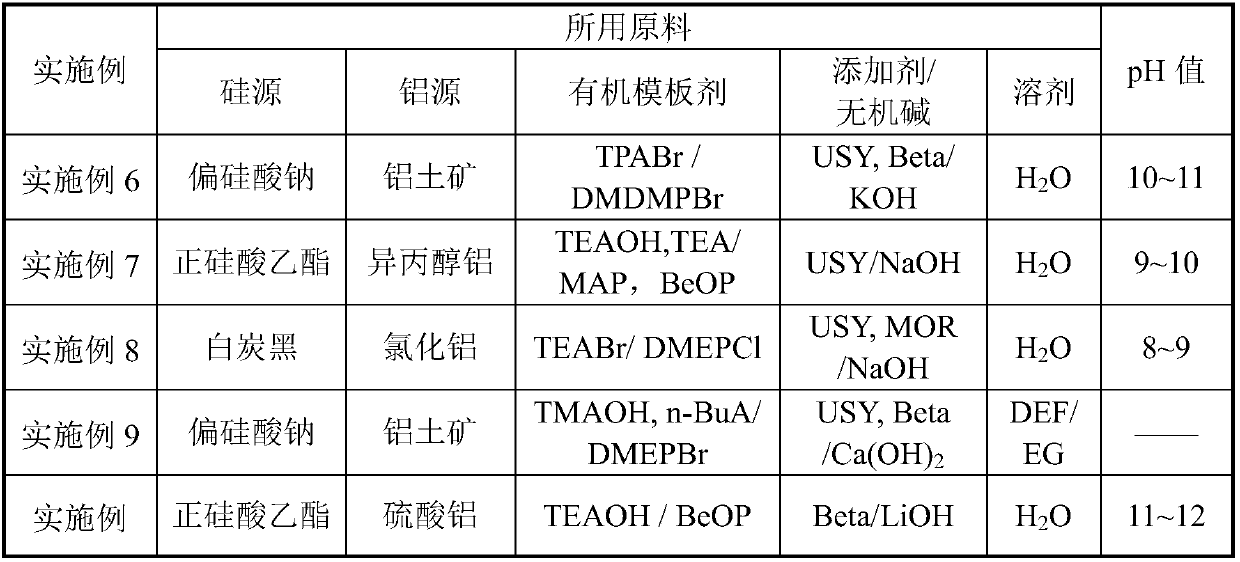

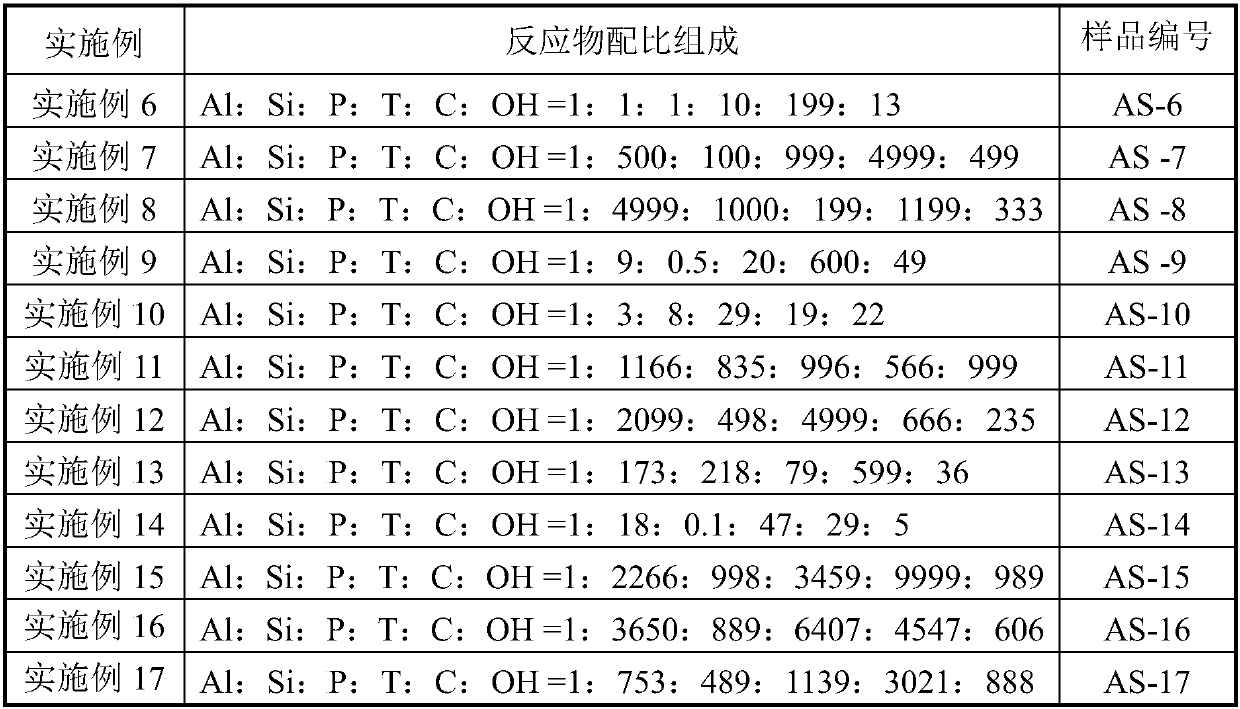

Examples

Embodiment 1

[0041] Synthesis of AEI Composite Molecular Sieves

[0042] Take by weighing 3023.11g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O, purity ≥98%wt., 8.05mol] was dissolved in 5536.36mL deionized water, and after stirring evenly, the solution was divided into two parts by mass, 25% and 75%, respectively, and recorded as solution C 1 and solution C 2 , 303.32g of phosphoric acid [H 3 PO 4 , 85%wt., 2.63mol], 1168.56g of tetraethylammonium hydroxide solution [TEAOH, 25%, 1.43mol] and 1245.24g of ethylenediamine [DEA, 20.72mol] into C 1 solution, after continuing to stir for 5h, solution C was obtained 1 '; 2071.36g of silica sol [SiO 2 , 60%wt, 20.71mol] and 155.16g of USY molecular sieves, 9.23g of Beta molecular sieves and 1008.94g of N,N-dimethyl-2-ethylpiperidinium bromide [DMEPBr, 3.66mol] and 263.36g of 1-Methyl-4-aminopiperidine [MAP, 2.24mol] into C 2 In the solution, after fully stirring, add 333.46g of sodium hydroxide [NaOH, 8.33mol] into the above solution to adjus...

Embodiment 2

[0044] Synthesis of AEI Composite Molecular Sieves

[0045] Weigh 1020.44g of aluminum isopropoxide [Al(Pr) 3 4H 2 O, purity≥98%wt., 4.99mol] was dissolved in 2143.25mL deionized water, and after stirring evenly, the solution was divided into two parts according to the mass parts, which were respectively 80% and 20%, which were recorded as solution C 1 and solution C 2 , 2111.66g of ammonium hydrogen phosphate [(NH 4 ) 2 HPO 4 , 15.99mol], and 1286.61g of tetraethylammonium bromide [TEABr, 6.12mol] and 661.56g of triethylamine [TEA, 6.54mol] into C 1 solution, continue to stir for 1.0h to obtain solution C 1 '; 61.36g of white carbon black [SiO 2 ,99wt.%, 1.02mol] and 32.26g of USY molecular sieves, 9.13g of MOR molecular sieves and 118.36g of 1-benzyl-4-hydroxypiperidine [BeOP, 0.72mol], 52.39g of N,N-dimethyl Base-2-ethylpiperidinium chloride [DMEPCl, 0.25mol] into C 2 In the solution, after fully stirring, add 109.23g of potassium hydroxide [KOH, 1.95mol] into the ...

Embodiment 3

[0047] Synthesis of AEI Composite Molecular Sieves

[0048] Weigh 10.55g of aluminum sulfate [Al 2 (SO 4 ) 3 18H 2 O, purity ≥ 98wt.%, 0.02mol] was dissolved in 22.09mL deionized water, and after stirring evenly, the solution was divided into two parts by mass, 50% and 50%, respectively, and recorded as solution C 1 and solution C 2 , 6.64g of phosphoric acid [H 3 PO 4 , 85%wt., 0.06mol], 3.38g of tetrabutylammonium hydroxide [TPAOH, 0.01mol] and 15.69g of tetraethylammonium hydroxide [TEAOH, 25%, 0.03mol] into C 1 solution, continue to stir for 2.5h to obtain solution C 1 ’; 10.18g of acidic silica sol [SiO 2 , 40wt.%, 0.07mol], 3.11g of USY molecular sieves and 6.15g of 2,2,4,6,6-pentamethyl-2-azabicyclo[3.2.1]octane [PMNO, 0.03mol ] and 2.23g of N,N-dimethyl-3,5-dimethylpiperidinium bromide [DMDMPBr, 0.01mol] into C 2In the solution, after fully stirring, add 1.31g of lithium hydroxide [LiOH, 0.10mol] into the above solution to adjust the pH value of the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com