Supported uniform nickel-cobalt (Ni-Co) alloy catalyst and preparation method thereof

A technology of alloy catalyst and nickel-cobalt alloy, which is applied in the field of supported uniform nickel-cobalt alloy catalyst and its preparation, can solve the problems of affecting catalytic performance, uneven composition, coexistence of multi-phase alloys, etc., and achieve good catalytic activity and uniform composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

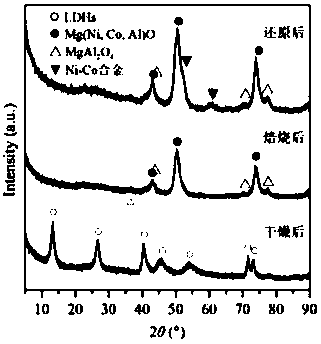

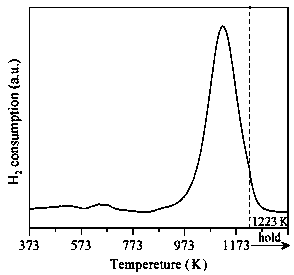

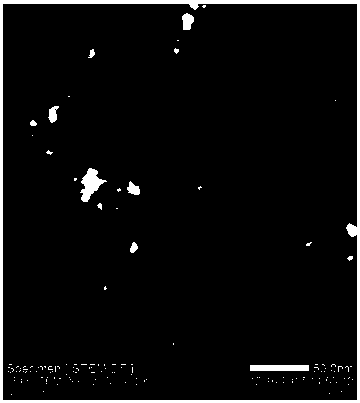

Embodiment 1

[0029] Accurately weigh 40 g of flaky NaOH solid, dissolve it in 500 mL of deionized water, stir for 10 minutes, and prepare a 2mol / L NaOH aqueous solution for use. According to the (Ni+Co+Mg):Al molar ratio of 3:1 and Ni:Co molar ratio of 3:1, weigh 1.3378gNi(NO 3 ) 2 ·6H 2 O, 0.4445g Co(NO 3 ) 2 ·6H 2 O, 10.8974g Mg(NO 3 ) 2 ·6H 2 O and 6.0846g Al(NO 3 ) 3 ·9H 2 O was dissolved in 100 mL of deionized water and stirred for 10 minutes to completely dissolve the nitrate to obtain a mixed solution. Press Na 2 CO 3 The molar amount is Al(NO 3 ) 3 ·9H 2 0.5 times the molar amount of O to weigh anhydrous Na 2 CO 3 X 0.8596g, dissolved in 100mL deionized water, as the bottom liquid. The mixed solution of nickel, cobalt, magnesium and aluminum was dripped into Na containing Na with a constant pressure funnel at a rate of 30 drops / min. 2 CO 3 Place the solution in a beaker and stir constantly. At the same time, use a peristaltic pump to slowly drip the NaOH solution of the precipitant ...

Embodiment 2

[0031] The process of Example 1 was repeated for the preparation of NaOH aqueous solution. Then press (Ni+Co+Mg):Al molar ratio 3:1 and Co:Ni molar ratio 1:1, and weigh 0.8919g Ni(NO 3 ) 2 ·6H 2 O, 0.8890g Co(NO 3 ) 2 ·6H 2 O, 10.8974g Mg(NO 3 ) 2 ·6H 2 O and 6.0846g Al(NO 3 ) 3 ·9H 2 O was dissolved in 100 mL of deionized water and stirred for 10 minutes to completely dissolve the nitrate to obtain a mixed solution. Press Na 2 CO 3 The molar amount is Al(NO 3 ) 3 ·9H 2 0.5 times the molar amount of O to weigh anhydrous Na 2 CO 3 X0.8596g, dissolved in 100mL deionized water, as the bottom liquid. The mixed solution of nickel, cobalt, magnesium and aluminum was dripped into Na containing Na with a constant pressure funnel at a rate of 30 drops / min. 2 CO 3 Place the solution in a beaker and stir constantly. At the same time, use a peristaltic pump to slowly drip the NaOH solution of the precipitant into the beaker at a rate of 35 drops / min. During the dripping process, keep the s...

Embodiment 3

[0033] The process of Example 1 was repeated for the preparation of NaOH aqueous solution. Then according to the molar ratio of (Ni+Co+Mg):Al 3:1 and Ni:Co molar ratio 1:3, weigh 0.4459g Ni(NO 3 ) 2 ·6H 2 O, 1.3334g Co(NO 3 ) 2 ·6H 2 O, 10.8974g Mg(NO 3 ) 2 ·6H 2 O and 6.0846g Al(NO 3 ) 3 ·9H 2 O was dissolved in 100 mL of deionized water and stirred for 10 minutes to completely dissolve the nitrate to obtain a mixed solution. Press Na 2 CO 3 The molar amount is Al(NO 3 ) 3 ·9H 2 0.5 times the molar amount of O to weigh anhydrous Na 2 CO 3 X0.8596g, dissolved in 100mL deionized water, as the bottom liquid. The mixed solution of nickel, cobalt, magnesium and aluminum was dripped into Na containing Na with a constant pressure funnel at a rate of 30 drops / min. 2 CO 3 Place the solution in a beaker and stir constantly. At the same time, use a peristaltic pump to slowly drip the NaOH solution of the precipitant into the beaker at a rate of 35 drops / min. During the dripping process, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com