Technology for preparing high-purity 2-hydroxyethyl acrylate

A preparation technology of hydroxyethyl acrylate, which is applied in the field of preparation technology of high-purity hydroxyethyl acrylate, and can solve problems such as polymer refractory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

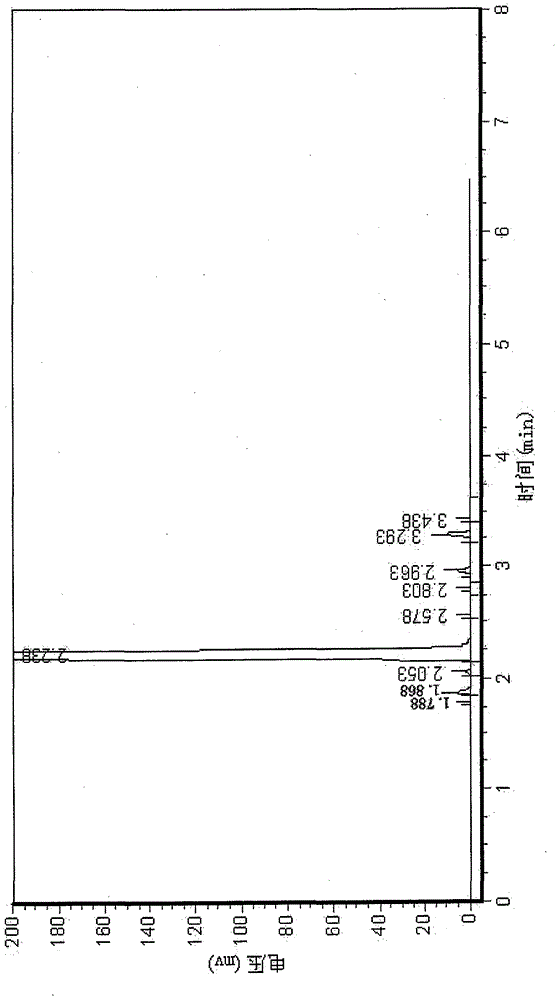

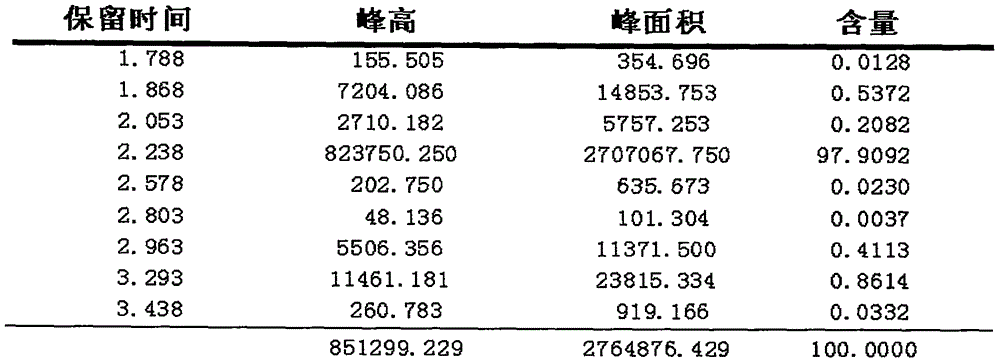

Image

Examples

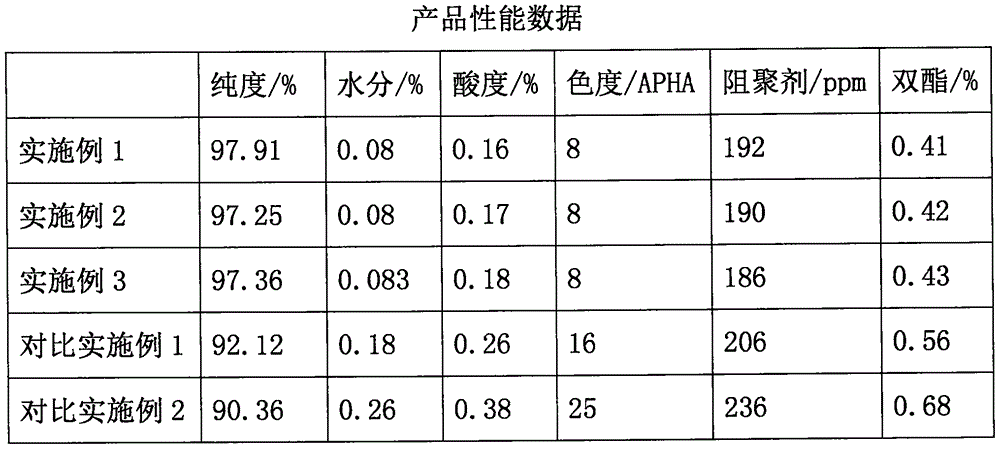

Embodiment 1

[0031] see Figure 1-Figure 2 As shown, the technical scheme adopted in this embodiment is: under vacuum conditions, 2000kg of acrylic acid is pumped in by a vacuum unit, and the mass fraction is 2.0% chromium acetate, 13 × 10 -4 Hydroquinone and p-hydroxyanisole, after the completion, ensure that the vacuum is 0.75Mpa, add ethylene oxide after the metering tank is replaced by nitrogen, ensure that the oxygen / nitrogen volume ratio is 0.25%, and drop it under the condition of steam heating to 80°C Add ethylene oxide, by controlling the drop rate of ethylene oxide to ensure that the pressure is ≤ 60KPa, the molar ratio of ethylene oxide to acrylic acid is 1.02:1, the reaction temperature is controlled at 90°C by cooling with cooling water, and the reaction time is 1.5 hours; After the addition is completed, turn off the cooling water and raise the temperature naturally. After the temperature drops, take a sample to detect that the mass percentage of acrylic acid is less than 0.5...

Embodiment 2

[0035] Under vacuum conditions, 2000kg of acrylic acid, chromium acetate with a mass fraction of 5.0%, 13×10 -4 of hydroquinone and paraben and 5 x 10 -3 After completion, ensure that the vacuum is at 0.75Mpa, fill in nitrogen to ensure that the oxygen / nitrogen volume ratio is 0.25%, add ethylene oxide dropwise under the condition of steam heating to 80°C, and ensure that the pressure is ≤ 60KPa by controlling the drop rate of ethylene oxide , the molar ratio of ethylene oxide to acrylic acid is 1.06:1, the reaction temperature is controlled at 90°C by cooling with cooling water, and the reaction time is 1.5 hours; after the dropwise addition, the cooling water is turned off and the temperature rises naturally, and after the temperature drops, a sample is taken to detect that the mass percentage of acrylic acid is less than 0.5% is regarded as the completion of the addition reaction;

[0036]Thin-film evaporator is used for weight removal under vacuum conditions to obtain pri...

Embodiment 3

[0038] Under vacuum conditions, 2000kg of acrylic acid, chromium acetate with a mass fraction of 2.0%, 13×10 -4 of hydroquinone and paraben and 5 x 10 -3 After completion, ensure that the vacuum is at 0.75Mpa, fill in nitrogen to ensure that the oxygen / nitrogen volume ratio is 0.25%, add ethylene oxide dropwise under the condition of steam heating to 85°C, and ensure that the pressure is ≤ 60KPa by controlling the drop rate of ethylene oxide , the molar ratio of ethylene oxide to acrylic acid is 1.02:1, the reaction temperature is controlled at 90°C by cooling with cooling water, and the reaction time is 1.5 hours; after the dropwise addition is completed, the cooling water is turned off and the temperature rises naturally. After the temperature drops, the mass percentage of acrylic acid is less than 0.5% is regarded as the completion of the addition reaction;

[0039] Thin-film evaporator is used for weight removal under vacuum conditions to obtain primary distillation produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com