Moving-bed reactor, solid acid alkylation reaction system and solid acid alkylation reaction method

A moving bed reactor, alkylation technology, applied in chemical instruments and methods, chemical/physical processes, production of liquid hydrocarbon mixtures, etc. Contact efficiency, the effect of improving contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

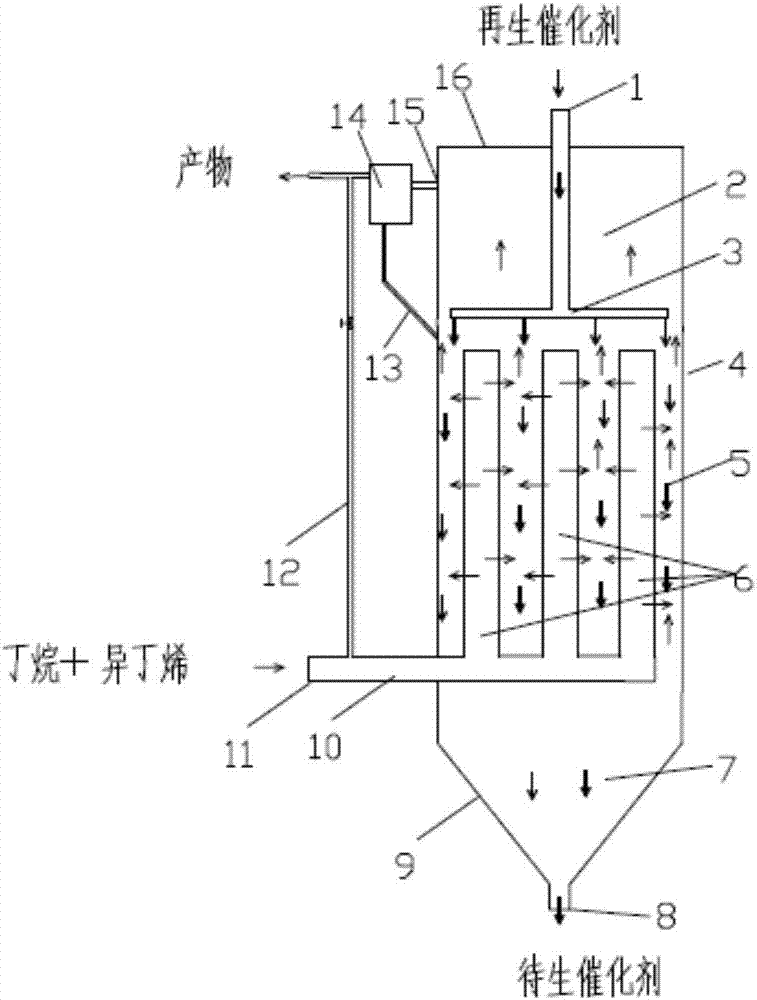

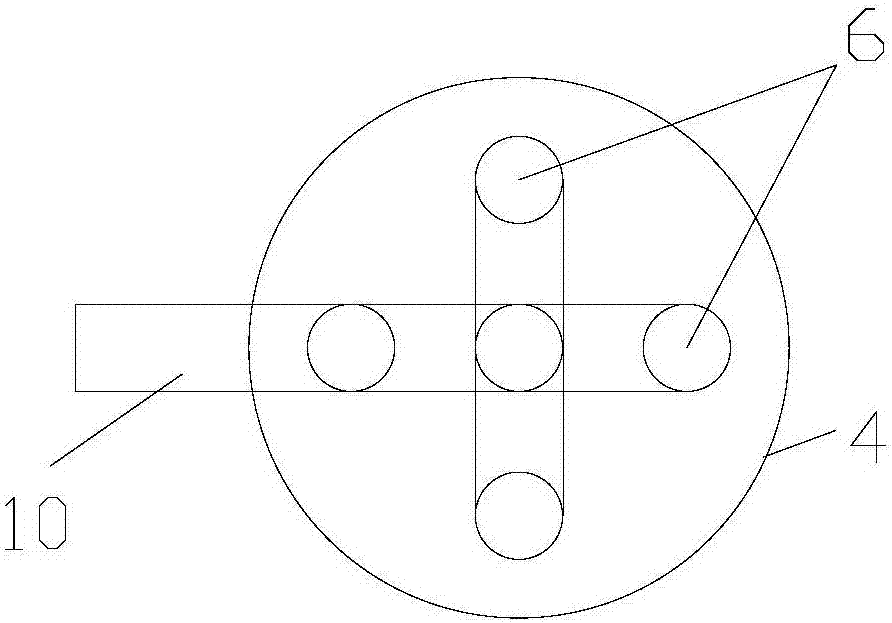

Embodiment 1

[0070] in the attached image 3 The solid acid alkylation reaction is carried out on the medium-sized experimental device of the moving bed reactor shown. The inner diameter of the reaction zone of the reactor is 200 mm, the height is 3000 mm, the inner diameter of the settling area is 500 mm, and the height is 1000 mm. 5 metal tubes with a diameter of 30mm filled with sieve holes, and the metal tubes are covered with a layer of wire mesh. The reaction raw material is a mixture of isobutane and butene, and the ratio of the two is 14:1. The fluid of the reaction product fluid returned to the reaction zone after liquid-solid separation accounts for 90% of the total fluid. The superficial flow rate of the liquid raw material mixture in the reaction zone is 0.04m / s, the corresponding total feed rate is 2360kg / h, and the mass space velocity of olefins is 0.2h -1 . The catalyst is a molecular sieve spherical catalyst loaded with metal Pt, the content of the active metal Pt is 0.3w...

Embodiment 2

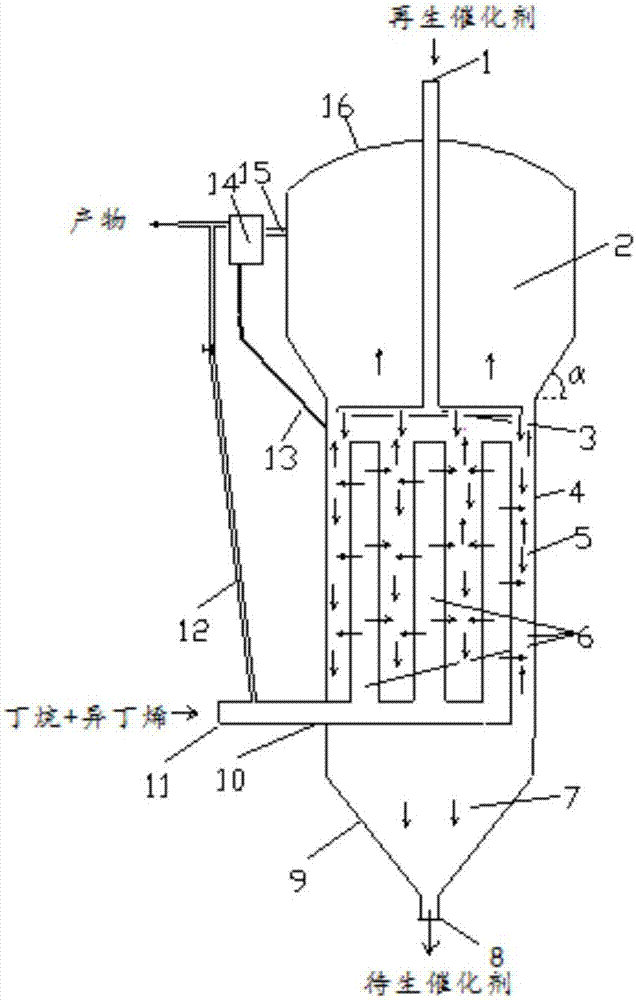

[0072] in such as Figure 4 The solid acid alkylation reaction is carried out on the medium-sized experimental device of the moving bed reactor shown. The inner diameter of the reaction zone of the reactor is 200mm, the height is 3000mm, the inner diameter of the settling zone is 500mm, and the height is 1000mm. The device is composed of a fan-shaped cylinder made of Johnson mesh. The fluid distributor in the central area is a metal tube with a diameter of 30mm filled with screen holes. The metal tube is covered with a layer of wire mesh. The reaction raw material is a mixture of isobutane and butene, and the ratio of the two is 10:1. The fluid of the reactant fluid returned to the reaction zone after liquid-solid separation accounts for 60% of the total fluid. The superficial flow rate of the liquid raw material mixture in the reaction zone is 0.05m / s, the corresponding total feed rate is 3000kg / h, and the mass space velocity of olefin is 0.2h -1 . The liquid products are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com