Method for preparing carbon nano fiber

A carbon nanofiber and tellurium nanotechnology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problem that the surface of the product is difficult to functionalize, and achieve the effect of mild preparation conditions, high application value, and simple process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

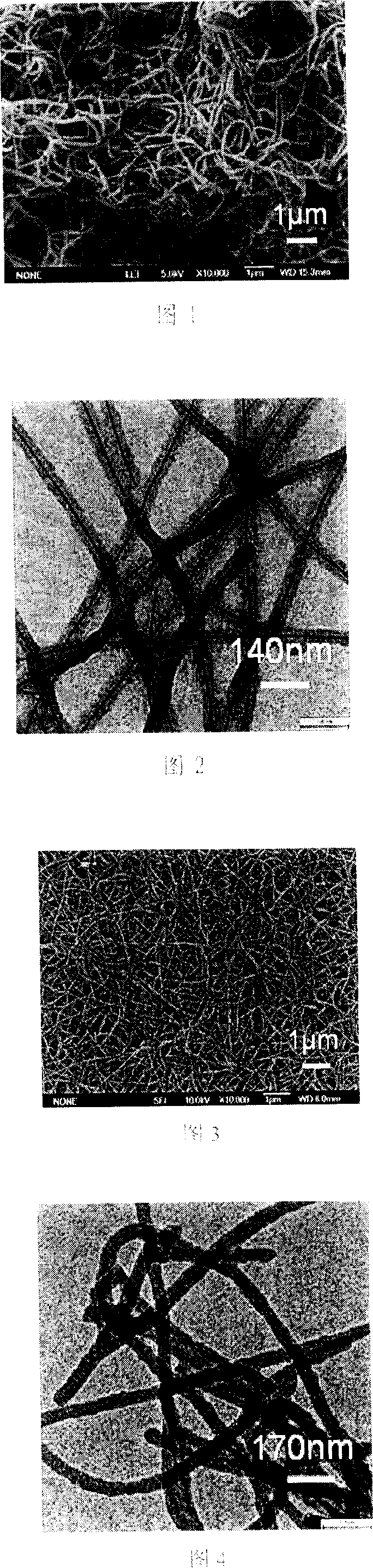

[0023] The tellurium nanowires synthesized in the prior art all have relatively large wire diameters and small specific surface areas. In the present invention, we adopt strong reducing agent (hydrazine hydrate), under relatively higher reaction temperature (160-200 ℃) and polymer surfactant polyvinylpyrrolidone exist, first hydrothermal synthesis has higher ratio Nanowires of semiconductor tellurium with a surface area and wire diameter of 4-9nm; then using the nanowires of semiconductor tellurium as a template, using sugar carbohydrates to synthesize carbon-coated tellurium nanocables at a lower temperature, as a preparation An intermediate product of carbon nanofibers; the tellurium core of the semiconductor tellurium nanocable is removed by oxidation, and finally carbon nanofibers are obtained.

[0024] 0.6g polyvinylpyrrolidone and 0.1107g Na 2 TeO 3 , placed in a reaction kettle with a capacity of 30ml, add 21ml of distilled water to dissolve, then add 1ml of hydrazine...

Embodiment 2

[0036] 0.2g polyvinylpyrrolidone and 0.1584gNa 2 TeO 3 , placed in a reaction kettle with a capacity of 30ml, add 21ml of distilled water to dissolve, then add 1ml of hydrazine hydrate and 2ml of ammonia water in sequence, stir, seal the reaction kettle, put it in an oven at 180°C, keep it for 8 hours, and cool it down to room temperature naturally. The obtained product was precipitated with 40ml of acetone, washed with distilled water and absolute ethanol several times in sequence to remove impurities, and obtained semiconductor tellurium nanowires.

[0037]Take 0.06 grams of tellurium nanowires, disperse them in 24ml of water, add 0.3 grams of β-cyclodextrin, stir and dissolve, then transfer to a 30ml reaction kettle, seal the reaction kettle, and place it in an oven at 180°C for 4 hours , cooled naturally to room temperature; the product was washed several times with distilled water and absolute ethanol, and after drying, a carbon-coated tellurium nanocable was obtained. ...

Embodiment 3

[0045] 1.2g polyvinylpyrrolidone and 0.0528gNa 2 TeO 3 , placed in a reaction kettle with a capacity of 30ml, add 21ml of distilled water to dissolve, then add 1ml of hydrazine hydrate and 2ml of ammonia water in turn, stir, seal the reaction kettle, put it in an oven at 190°C, keep it for 6 hours, and then naturally cool to room temperature ; The product obtained was precipitated with 40ml of acetone, and washed several times with distilled water and absolute ethanol in turn to remove impurities and obtain nanowires of semiconductor tellurium.

[0046] Take 2.4 mg of the above-mentioned tellurium nanowires, disperse them in 24 ml of water, add 7.5 g of glucose, stir to dissolve, transfer to a 30 ml reaction kettle, seal the reaction kettle, put it in an oven at 190°C for 8 hours, and cool it down to room temperature naturally ; The product was washed several times with distilled water and absolute ethanol, and then dried to obtain carbon-coated tellurium nanocables.

[0047...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com