Anti-aging method for polymer materials

A polymer material and anti-aging technology, applied in the field of polymer material preparation, can solve the problems of high toxicity and unenvironmental protection of antioxidants, and achieve the effect of prolonging service life and improving thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

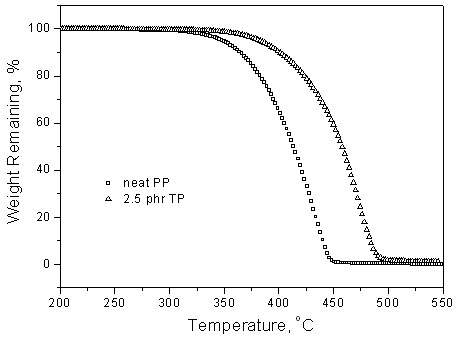

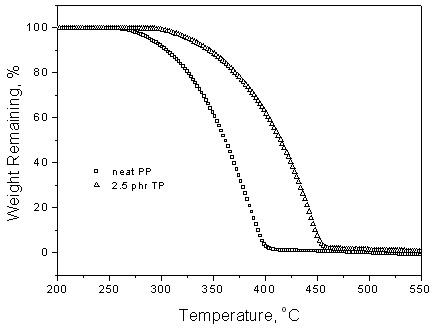

[0025] 10 grams of tea polyphenols and 1000 grams of polypropylene were extruded and granulated by twin-screw, and then the extruded pellets were subjected to thermogravimetric analysis (the heating rate was 5°C / min). The thermogravimetric curves of polypropylene samples in nitrogen protection and air atmosphere are as follows: figure 1 and figure 2 shown.

[0026] It can be seen from the figure that tea polyphenols as heat stabilizers and thermal oxygen stabilizers have a very significant effect on the anti-aging effect of polypropylene. After adding tea polyphenols, the thermal stability of polypropylene in nitrogen and air The thermo-oxidative stability of the polypropylene was significantly improved, and its 5% weight loss temperature increased by about 34 ° C and 38 ° C, respectively, indicating that tea polyphenols are very effective heat stabilizers and thermo-oxygen stabilizers for polypropylene.

Embodiment 2

[0028] The natural rubber is mixed on the open mill according to the formula in Table 1, and then vulcanized on a flat vulcanizer (the vulcanization temperature is 143°C). The aging resistance to hot air is tested according to the GB / T3512-1983 standard, and the aging temperature is 90°C. , the time is 12 days, 24 days and 48 days respectively. The mechanical properties of formula 1 and formula 2 before and after aging are shown in Table 2 below. It can be seen from Table 2 that after adding pine bark polyphenols to natural rubber, the aging resistance of natural rubber is significantly improved. Natural rubber is an efficient anti-aging agent.

[0029] Table 1 Natural rubber formula table

[0030]

[0031] TMTD*: Tetramethylthiuram disulfide, NOBS**: N-oxydiethylene-2-benzothiazolesulfenamide, 4010NA***: N-isopropyl-N'-phenylpara phenylenediamine

[0032] Table 2 Mechanical properties before and after aging

[0033]

Embodiment 3

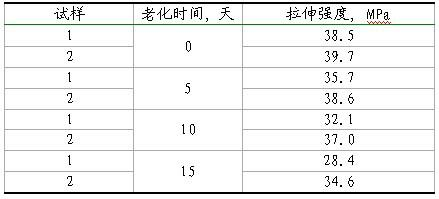

[0035]The polyurethane was mixed uniformly with an internal mixer according to the formula in Table 3, and then the uniformly mixed sample was molded into a thin sheet with a thickness of 1 mm, and then the artificial accelerated aging box (Z-UV type) was used to carry out according to ASTM G53296 standard, and irradiated The power is 3.2 kW, the irradiation wavelength range is 280-400 nm, and the temperature is about 70-75 ℃. The tensile strengths of formulation 1 and formulation 2 before and after aging are shown in Table 4. It can be seen from Table 4 that after adding tannic acid to polyurethane, the aging resistance is significantly improved, indicating that tannic acid is an efficient antioxidant for polyurethane.

[0036] Table 3 Polyurethane formula table

[0037]

[0038] Table 4 Mechanical properties before and after aging

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com